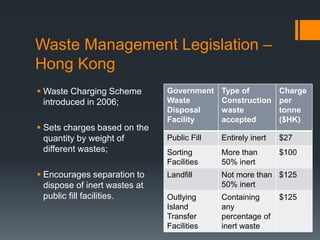

This document summarizes a presentation on construction and demolition waste recycling and provides legislative comparisons from Denmark, Hong Kong, and Queensland. It finds that Queensland is recycling only 42% of construction waste, compared to over 90% in Denmark and other countries. The presentation recommends that Queensland implement policies like landfill levies, recycling bans, and mandates for source separation to increase recycling rates as done successfully in other regions.