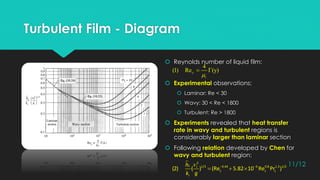

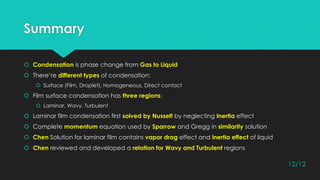

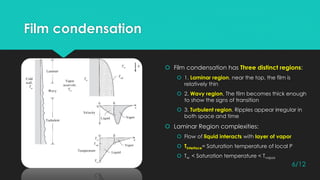

This document discusses condensation and film surface condensation on vertical surfaces. It defines condensation as the phase change from gas to liquid, and describes different types including surface, homogeneous, and direct contact condensation. For film surface condensation, it notes there are three regions - laminar, wavy, and turbulent - depending on the Reynolds number of the liquid film. It reviews the derivation of the laminar film condensation equation first solved by Nusselt, and improvements made by Sparrow and Gregg and Chen to account for inertia effects and vapor drag. Finally, it presents Chen's developed relation for calculating the heat transfer coefficient in the wavy and turbulent film regions.

![Laminar Film – Momentum Equation

Momentum equation for simplified laminar film:

Because of slenderness of the film:

Substituting:

Assuming negligible Inertia [Solved by Nusselt]:

2

2

(1) l l l

v v dP v

u v g

x y dy x

2

2

(3) ( )l l l v

Sinking Effect

FrictionInertia

v v v

u v g

x y x

(2) / vdP dy g

2 21

(4) ( , ) ( ) ( )

2

l g

l

g x x

v x y 7/12](https://image.slidesharecdn.com/condensationonverticalsurface-140505093257-phpapp02/85/Condensation-on-vertical-surface-7-320.jpg)

![Laminar Film – First thermodynamics law

The first law of thermodynamics:

Substituting conduction & (2):

Substituting (1)

Integrating from y=0

Local mass flow rate:

Vertical enthalpy inflow:

Assume linear temperature distribution:

3

0

(1) (y) ( )

3

l

l l v

l

g

vdx

,0

(2) [ ( )]l f P l satH v h c T T dx

''

(3) 0 ( ) hg wH H dH d q dy

'

,

3

[ ( )]

8

(4) ( )

fg

fg P l sat ts

h

a w

l

w h c T T

k

T T dy d

3

'

( )

(5)

( )

l l sat w

fg l v

kv T T

dy d

h g

1/4

'

4 (T T )

(6) ( )

( )

l l sat w

fg l v

kv

y y

h g

1sat

sat w

T T x

T T

8/12](https://image.slidesharecdn.com/condensationonverticalsurface-140505093257-phpapp02/85/Condensation-on-vertical-surface-8-320.jpg)