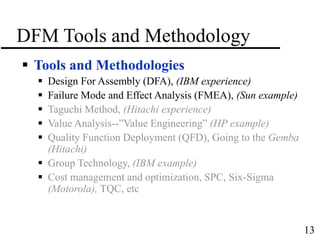

The document discusses design for manufacturability (DFM), which involves considering manufacturing requirements during product design. DFM aims to lower costs and development time while improving quality. It outlines the DFM process and various tools used, including design for assembly guidelines, failure mode and effects analysis, and Taguchi methods. DFM is presented as an integrated approach involving cross-functional teams to develop manufacturable products.