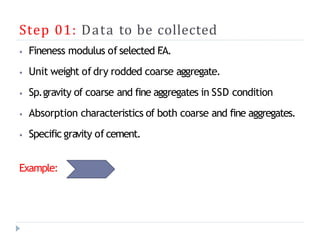

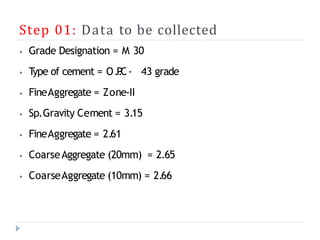

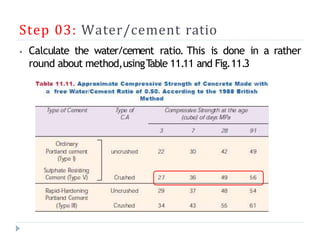

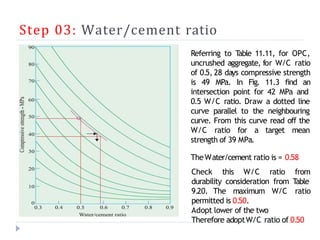

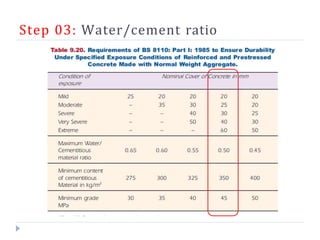

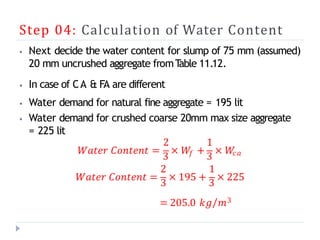

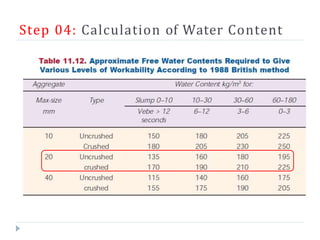

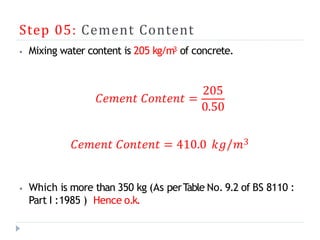

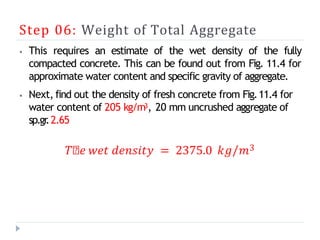

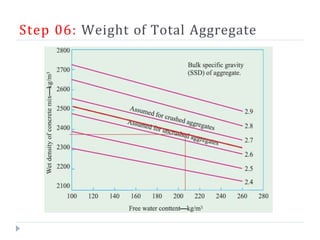

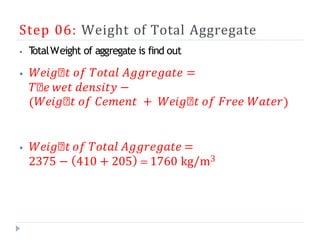

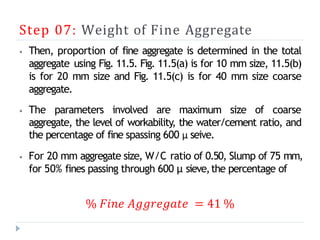

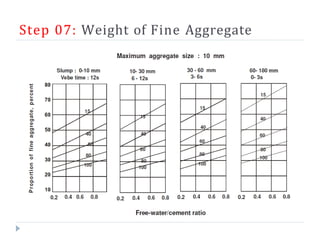

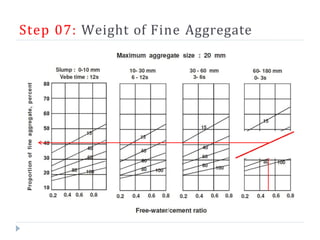

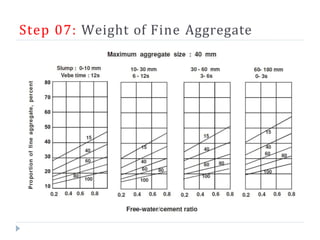

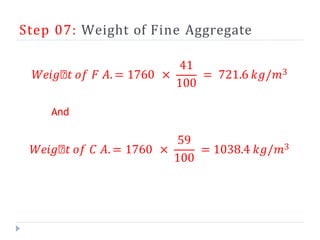

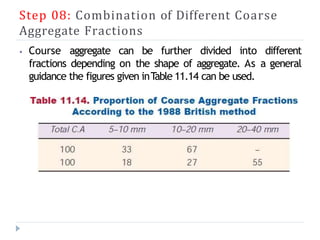

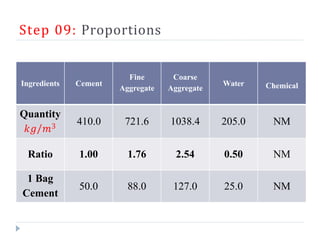

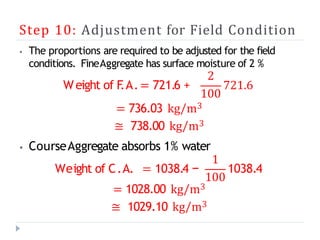

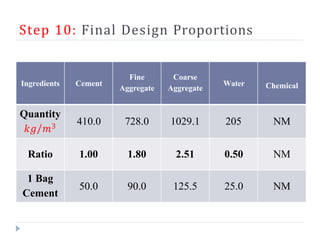

The document describes the DOE (Department of Environment) method for concrete mix design. It involves 10 steps: 1) collecting data on materials, 2) determining target mean strength, 3) calculating water-cement ratio, 4) determining water content, 5) determining cement content, 6) calculating total aggregate weight, 7) determining fine aggregate weight, 8) determining coarse aggregate fractions, 9) determining proportions, and 10) adjusting for field conditions. An example is provided where the final mix design proportions are cement: 410 kg/m3, fine aggregate: 728 kg/m3, coarse aggregate: 1029.1 kg/m3, and water: 205 kg/m3.