The document discusses various aspects of concrete mix design including:

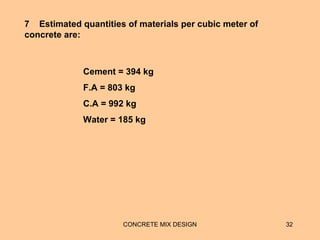

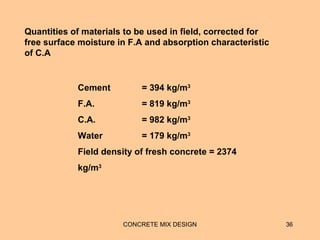

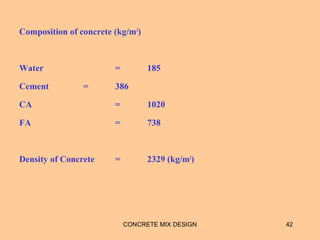

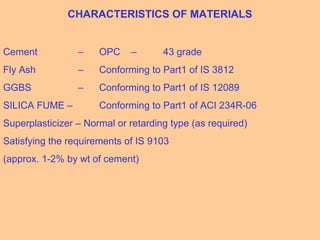

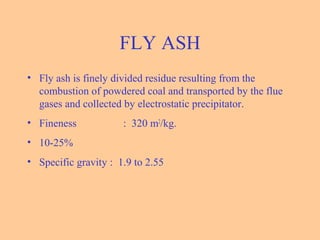

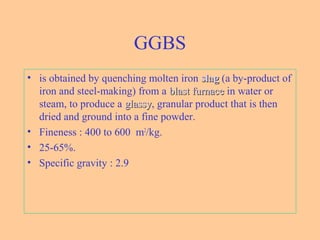

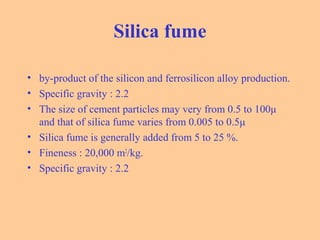

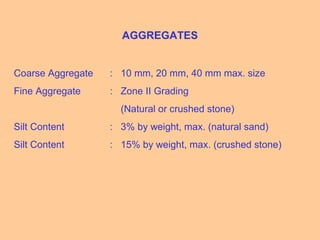

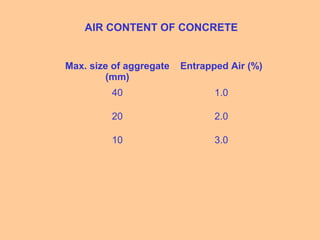

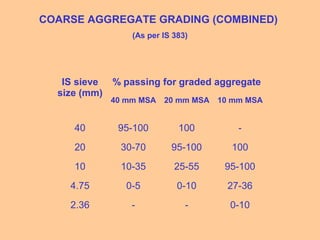

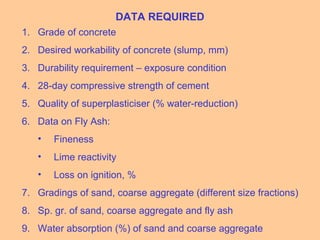

1. Materials used in concrete like cement, aggregates, water, and admixtures.

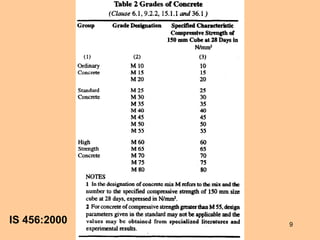

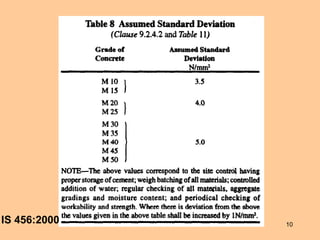

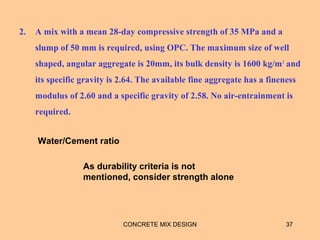

2. Types of concrete mixes including nominal and design mixes.

3. Trial mixes are conducted to verify the design mix proportions before use.

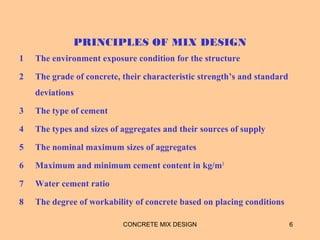

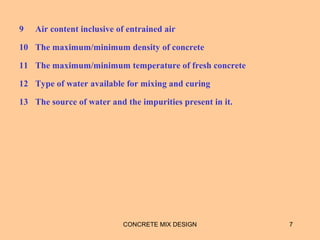

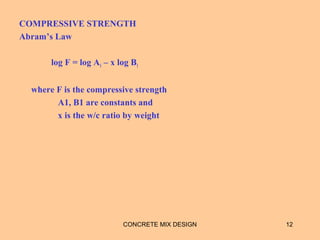

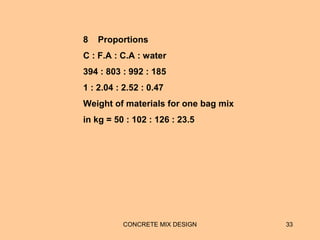

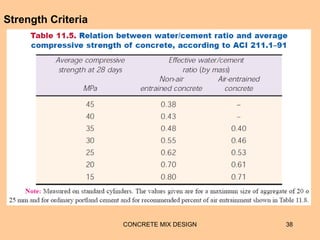

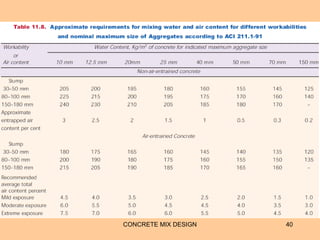

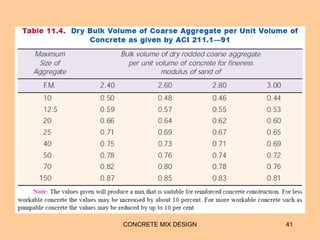

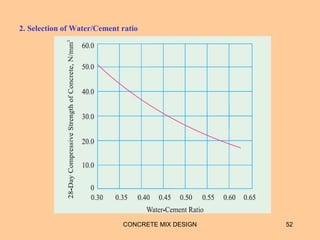

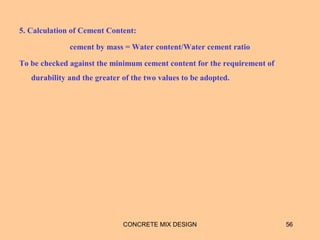

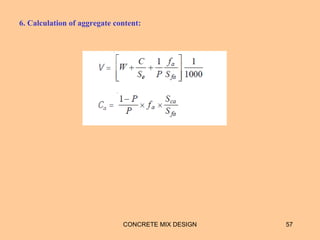

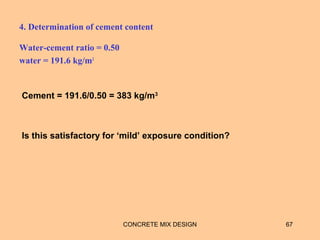

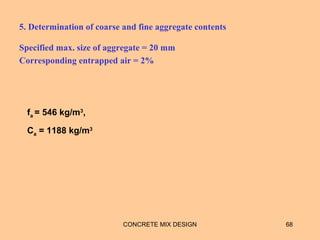

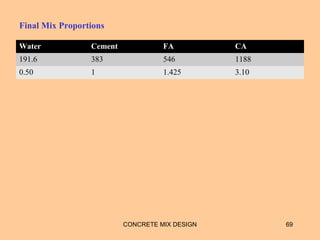

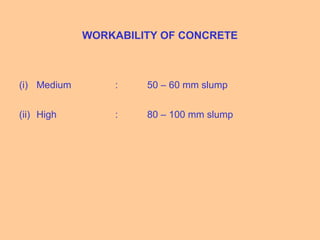

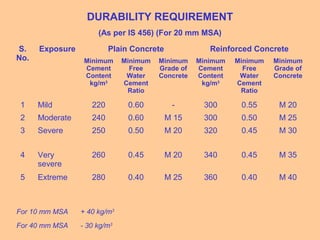

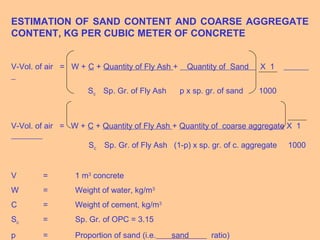

4. Mix design is defined as determining relative proportions of ingredients to achieve desired properties economically. Factors like strength, workability, and durability must be considered.

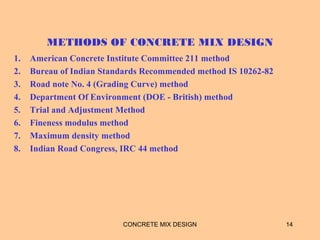

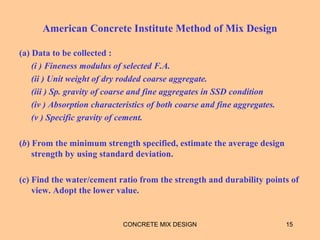

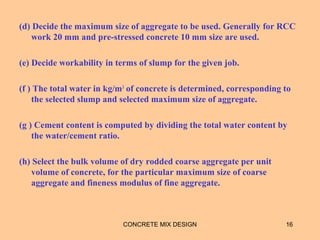

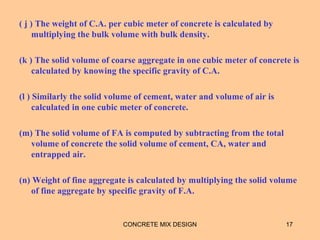

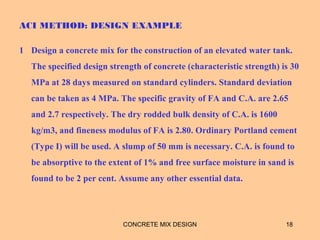

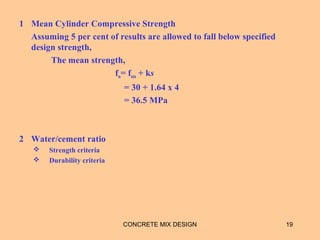

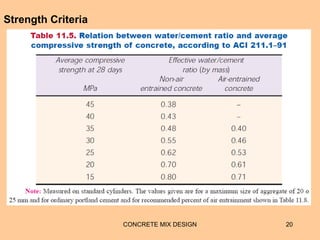

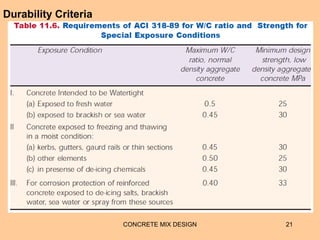

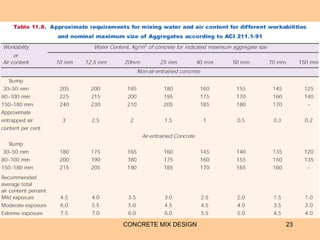

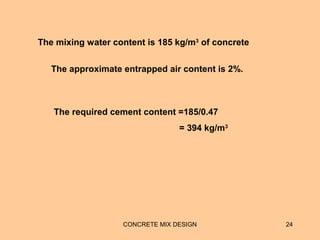

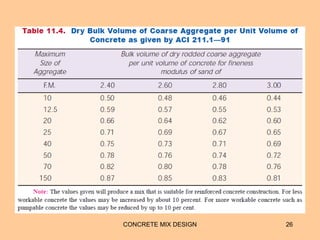

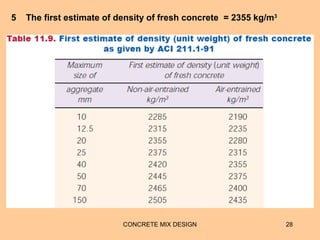

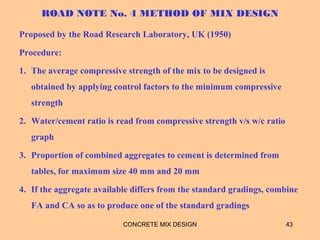

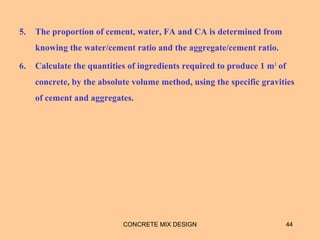

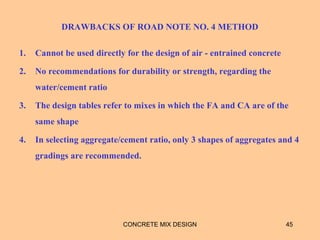

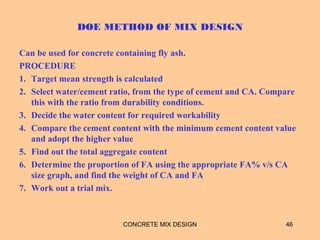

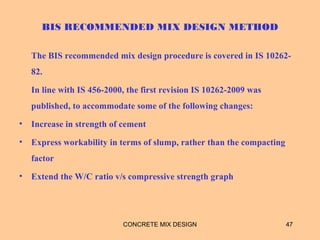

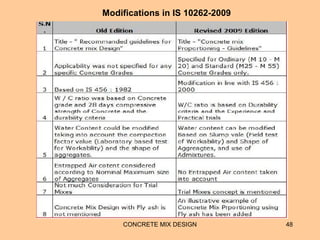

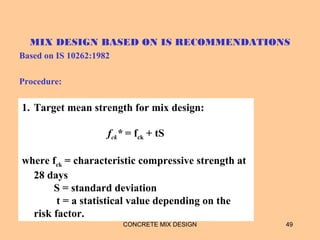

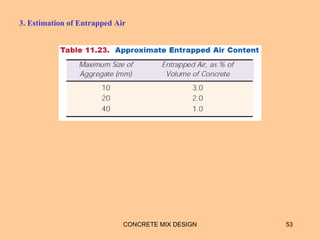

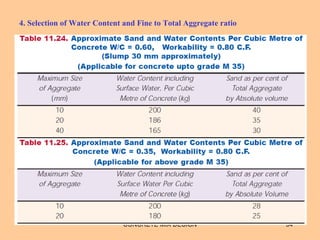

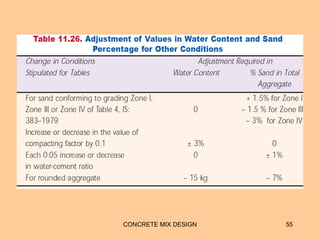

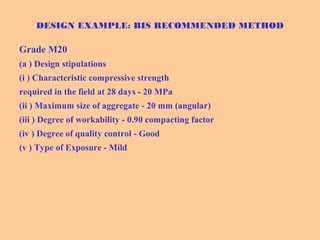

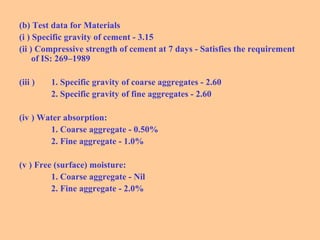

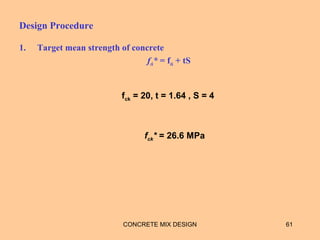

5. Methods for concrete mix design discussed include ACI, BIS, and Road Note No. 4 methods. Proportions are adjusted based on aggregate properties and desired concrete performance.