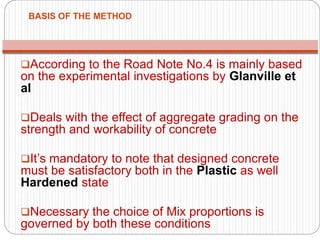

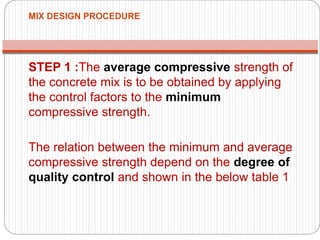

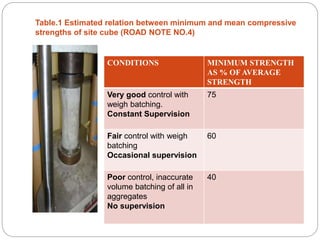

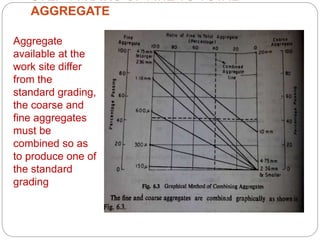

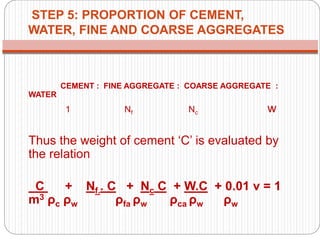

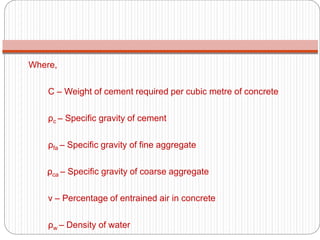

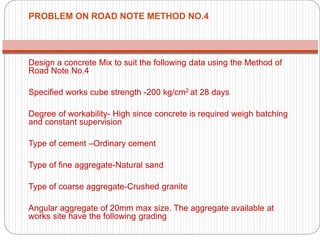

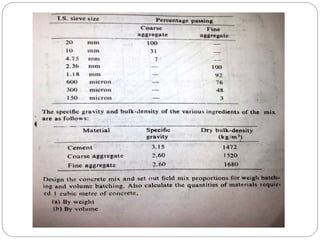

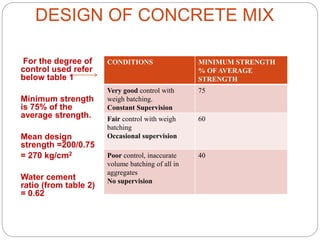

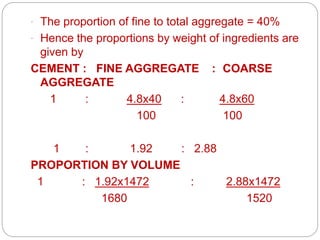

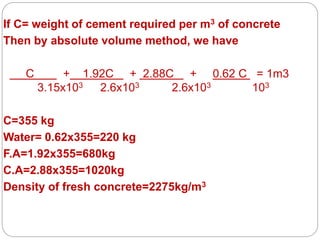

The document describes the Road Note Method No. 4 for mix design of concrete. It involves 5 steps: 1) determining average compressive strength, 2) selecting water-cement ratio, 3) choosing aggregate-cement ratio based on workability, 4) specifying fine-coarse aggregate ratio, and 5) calculating proportions. An example is provided to design a mix with 200 kg/cm2 strength using local aggregates graded within limits. The resulting mix has 355 kg cement, 220 kg water, 680 kg fine aggregate, and 1020 kg coarse aggregate per cubic meter of concrete.