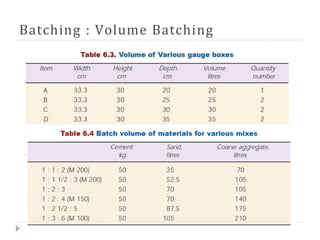

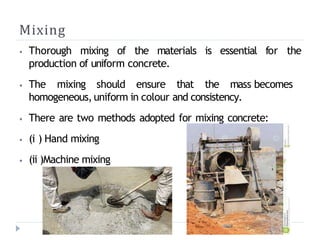

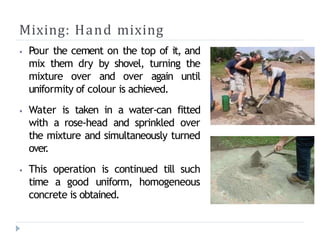

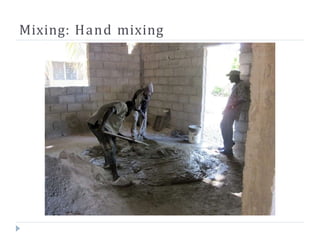

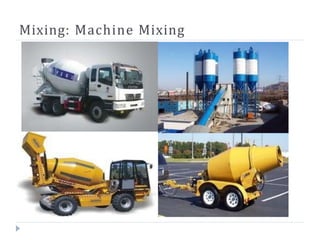

The document summarizes the process of manufacturing fresh concrete, including the key stages of batching, mixing, transporting, placing, and curing. It describes the batching process, noting that weigh batching is the correct method to ensure accuracy. It then explains the mixing stage, distinguishing between hand mixing and machine mixing, with machine mixing being more efficient and economical for larger jobs. Different types of machine mixers are also outlined.