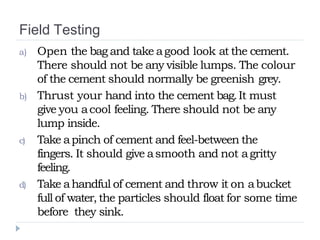

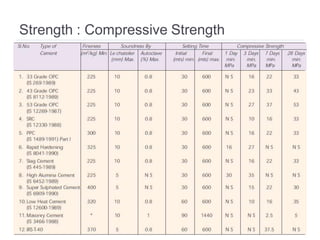

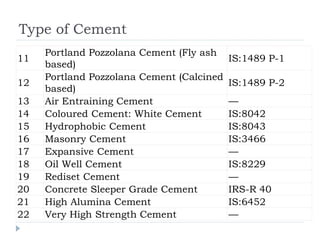

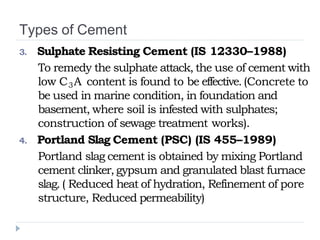

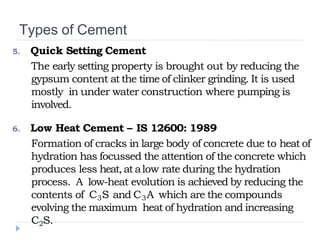

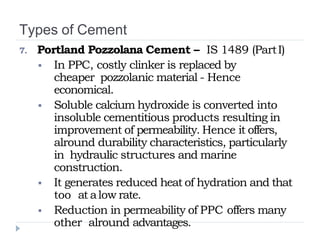

This document provides information on cement including field testing methods, physical properties like setting time, soundness, fineness, and strength. It describes how these properties are tested using methods like the Vicat apparatus, Le Chatelier test, and compressive strength testing. It also lists and describes various types of cement specified in Indian standards like ordinary Portland cement, rapid hardening cement, sulphate resisting cement, and Portland pozzolana cement.