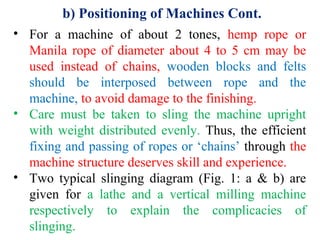

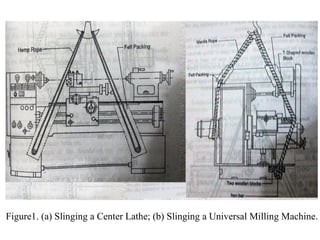

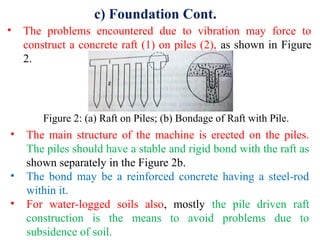

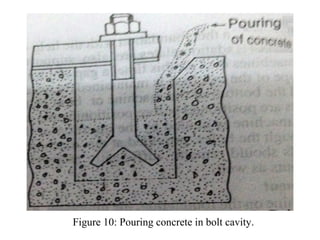

Chapter 1 provides an introduction to machine maintenance and installation, identifying the roles of maintenance professionals across various industries, and outlining the definition and importance of maintenance activities. It emphasizes the consequences of inadequate maintenance systems and discusses the general procedures for machine installation, including location, positioning, foundation work, leveling, and grouting. The chapter highlights the importance of various factors such as design, operational stages, and the technical aspects involved in ensuring proper installation and maintenance of machines in industrial settings.