This document describes the Bresenham's line drawing algorithm. It begins with the derivation of the algorithm, showing how it determines which pixel coordinates (xi+1, yi+1) are closest to the line between points (xi, yi) and (xi+1, yi+1) when m < 1. It then provides the algorithm steps, which include calculating differences, initializing variables, and using a decision parameter P to determine whether to increment x or y at each step. Finally, it provides a C program example to draw a line using the Bresenham's algorithm.

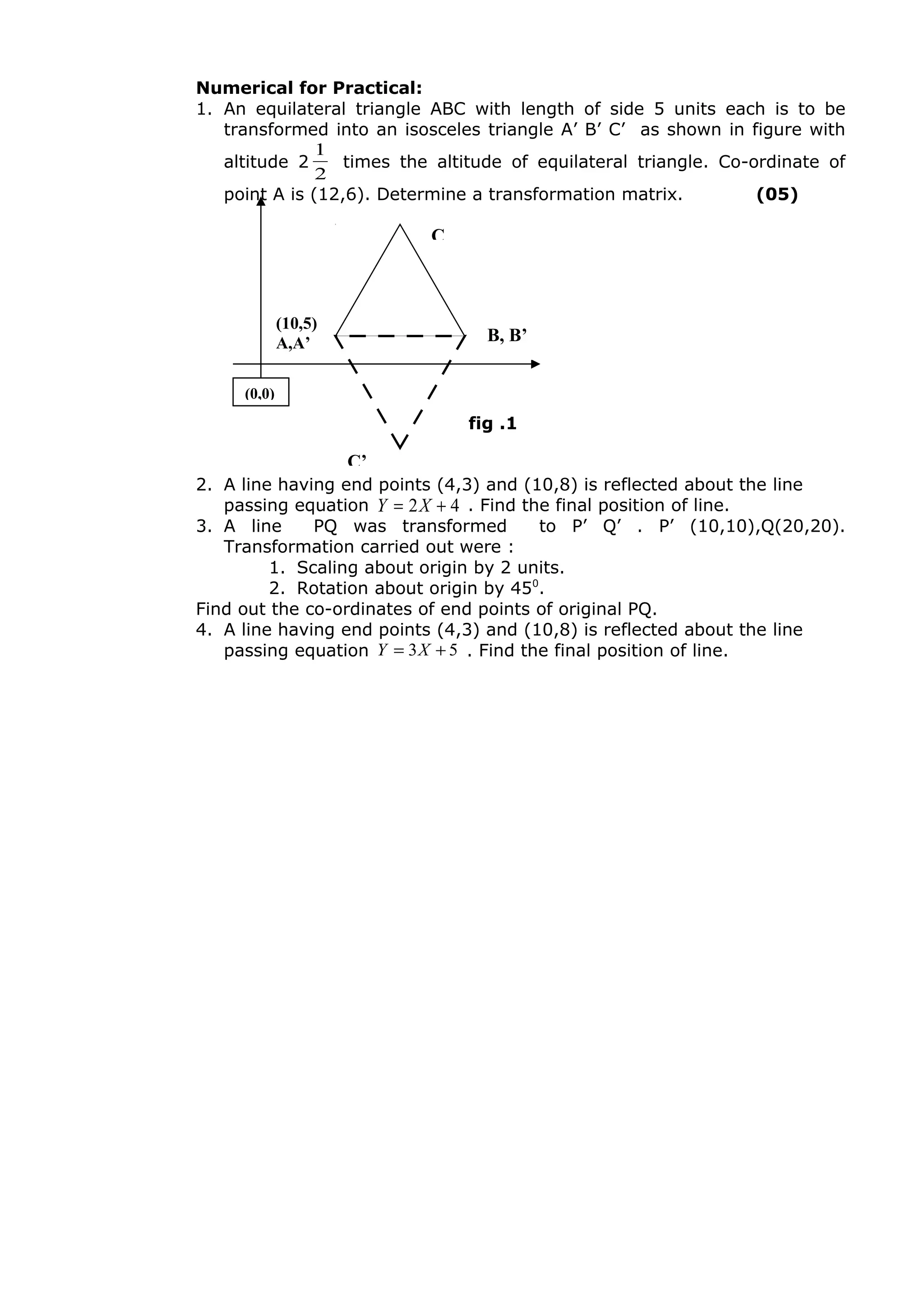

![Generation of Line using Bresenham’s Principle

(Derivation, Algorithm, Flow Chart, C-Programme and its

Output)

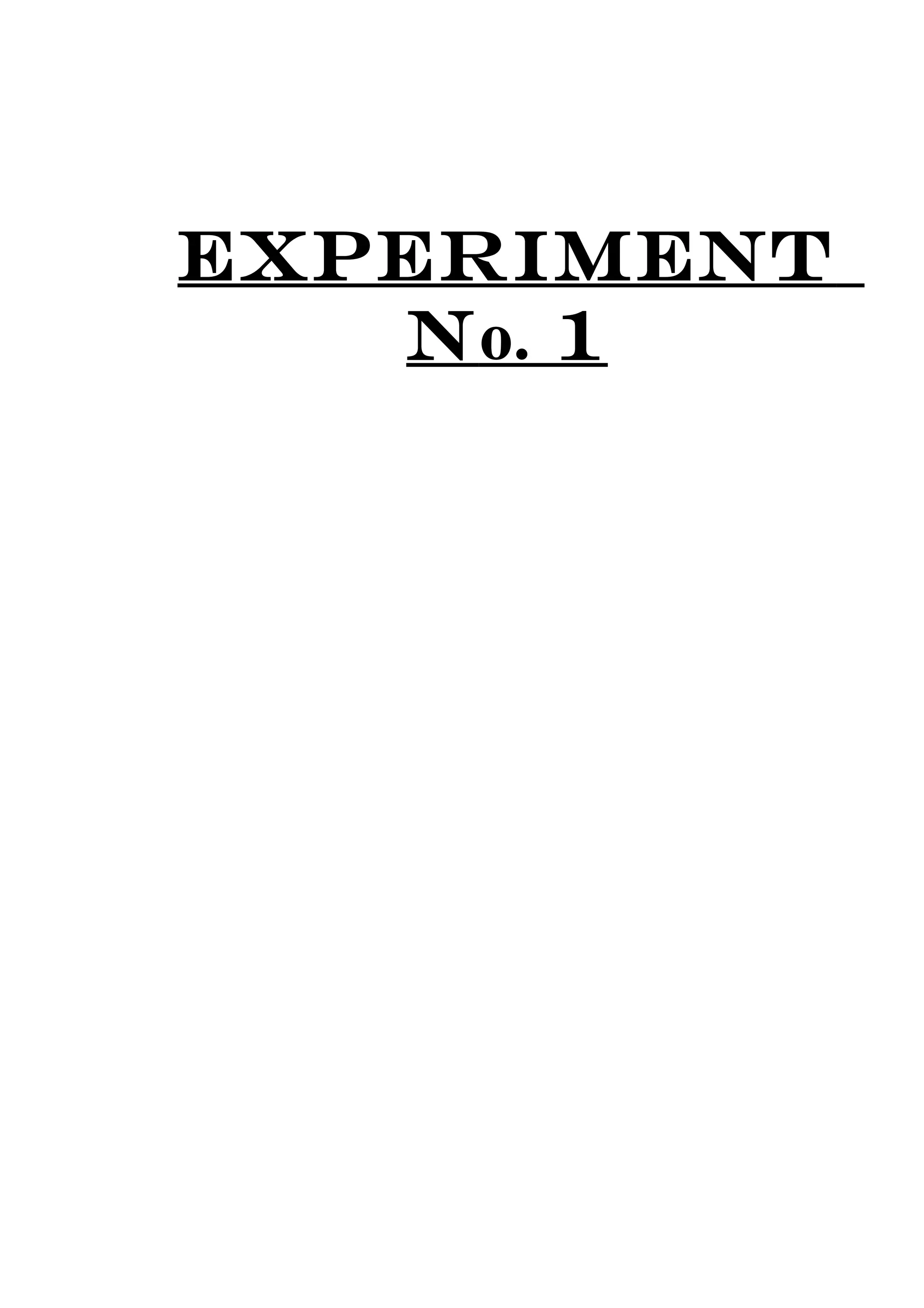

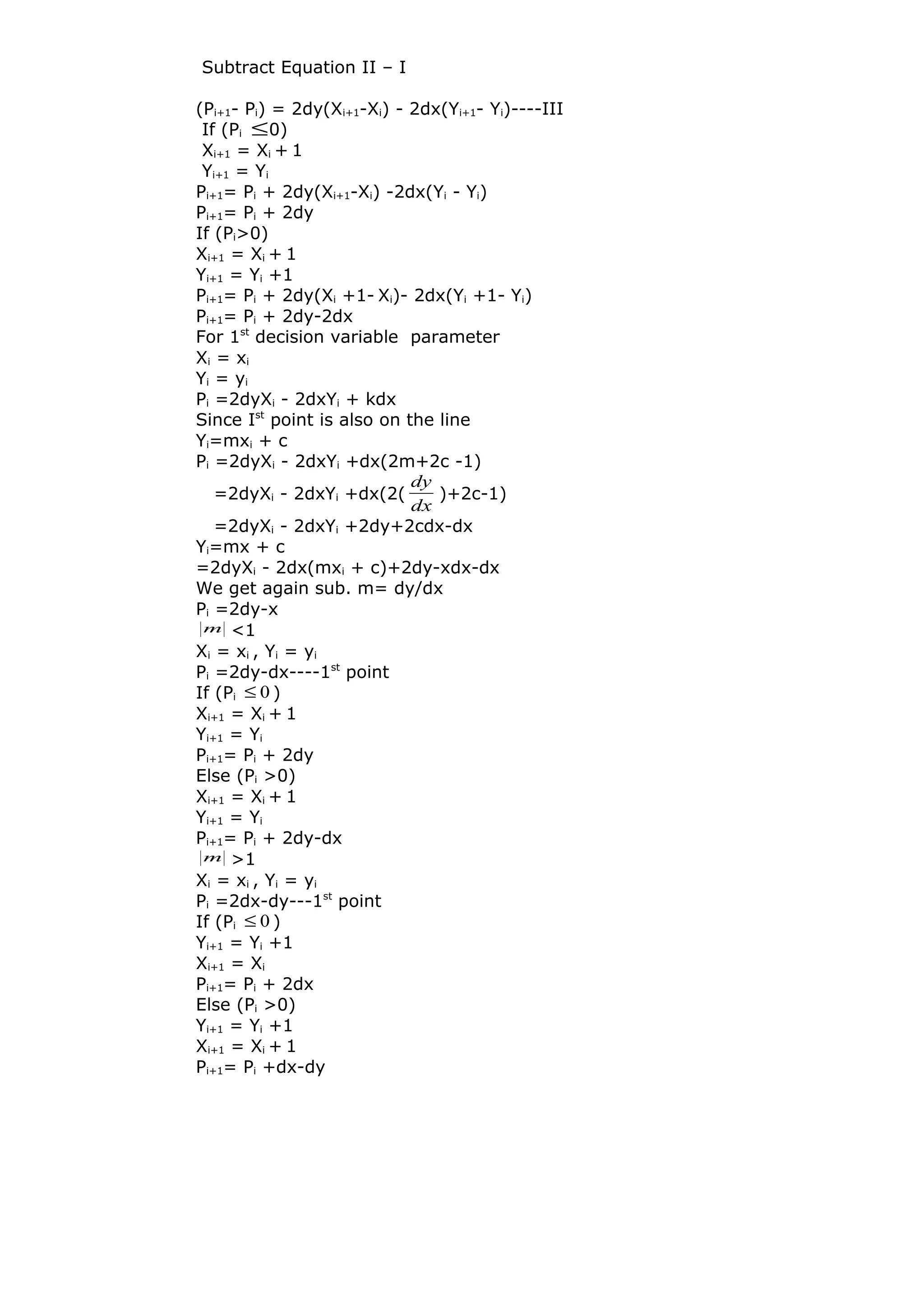

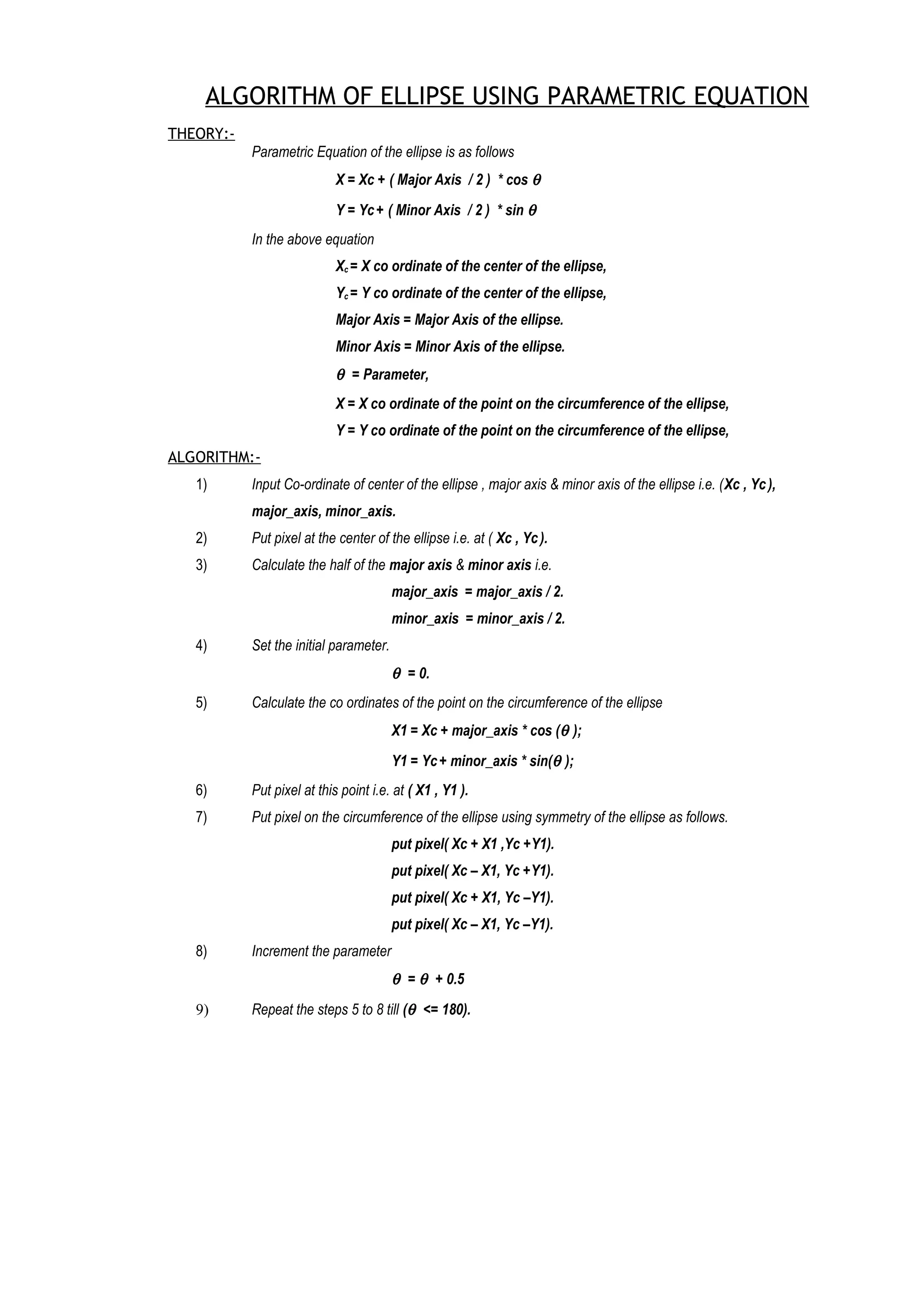

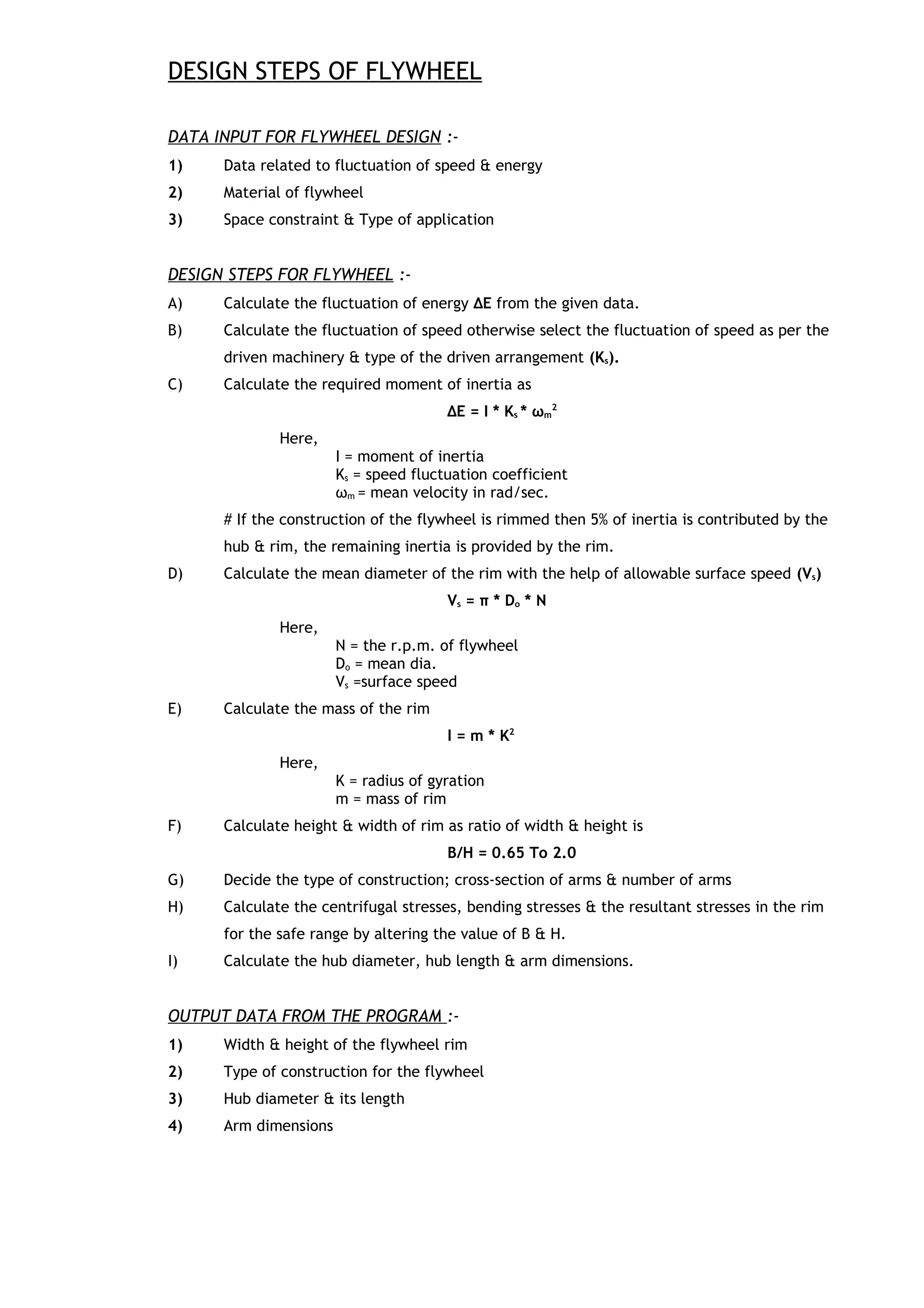

LINE USING BRESENHAM’S PRINCIPLE DERIVATION:

Let (Xi,Yi) be ith

pixel closed to the line & (Xi+1, Yi+1) be (i+1)th

pixel closed to

the line.

As m < 1

Xi+1 = Xi + 1

Yi+1 = Yi OR Yi +1

If (d1) ≤ (d2)

Yi+1 = Yi +1

If (d1 - d2) ≤0

Yi+1 = Yi

Else (d1 - d2) >0

Yi+1 = Yi +1

d1= Y- Yi

d2 = (Yi +1)-Y

(d1 - d2) = Y- Yi – (Yi+1) +Y

Yi+1 = Yi +1

= Y- Yi – Yi -1-Y

= 2Y-2Yi -1

Y=mx + c

X = Xi + 1

(d1 - d2) =2[m(Xi + 1) + c)]-2Yi -1

(d1 - d2) =2mXi+2m + 2c -2Yi -1

(d1 - d2) =2Yi Xi - 2Yi + (2Yi +2c-1)

(d1 - d2)= 2mXi - 2Yi +k

Where k = 2m + 2c-1

But m = dy/dx

(d1 - d2) =2(

dx

dy

)Xi - 2Yi +k

dx(d1 - d2) = 2dyXi - 2Yidx + kdx

Since dx is positive sign of (d1 - d2)will be the same as sign of dx (d1 - d2)

Hence dx(d1 - d2) can be taken as a decision parameter is to decide co-

ordinate of Yi +1

dx(d1 - d2) = Pi

Pi = 2dyXi - 2Yidx + k--------I

If Pi ≤0

Xi+1 = Xi + 1

Yi+1 = Yi

If Pi >0

Xi+1 = Xi + 1

Yi+1 = Yi +1

Similarly decision variable based (i+1)th

point

Pi+1= 2dyXi+1 -2Yi+1dx +k-----II

(0,0) xi

xi +1

yi+1

yi

1

2

d1

d2

Xm, Ym](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-10-2048.jpg)

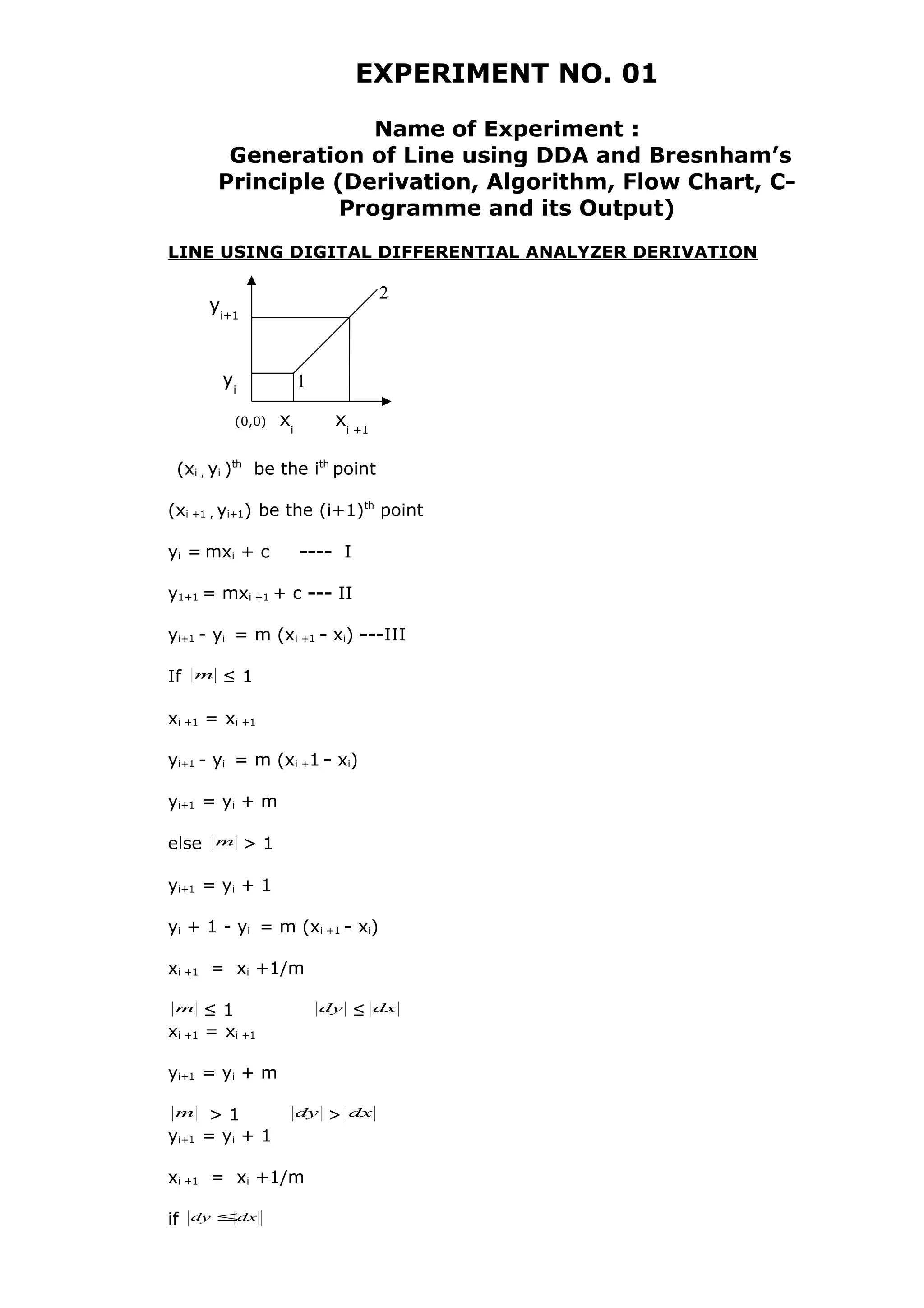

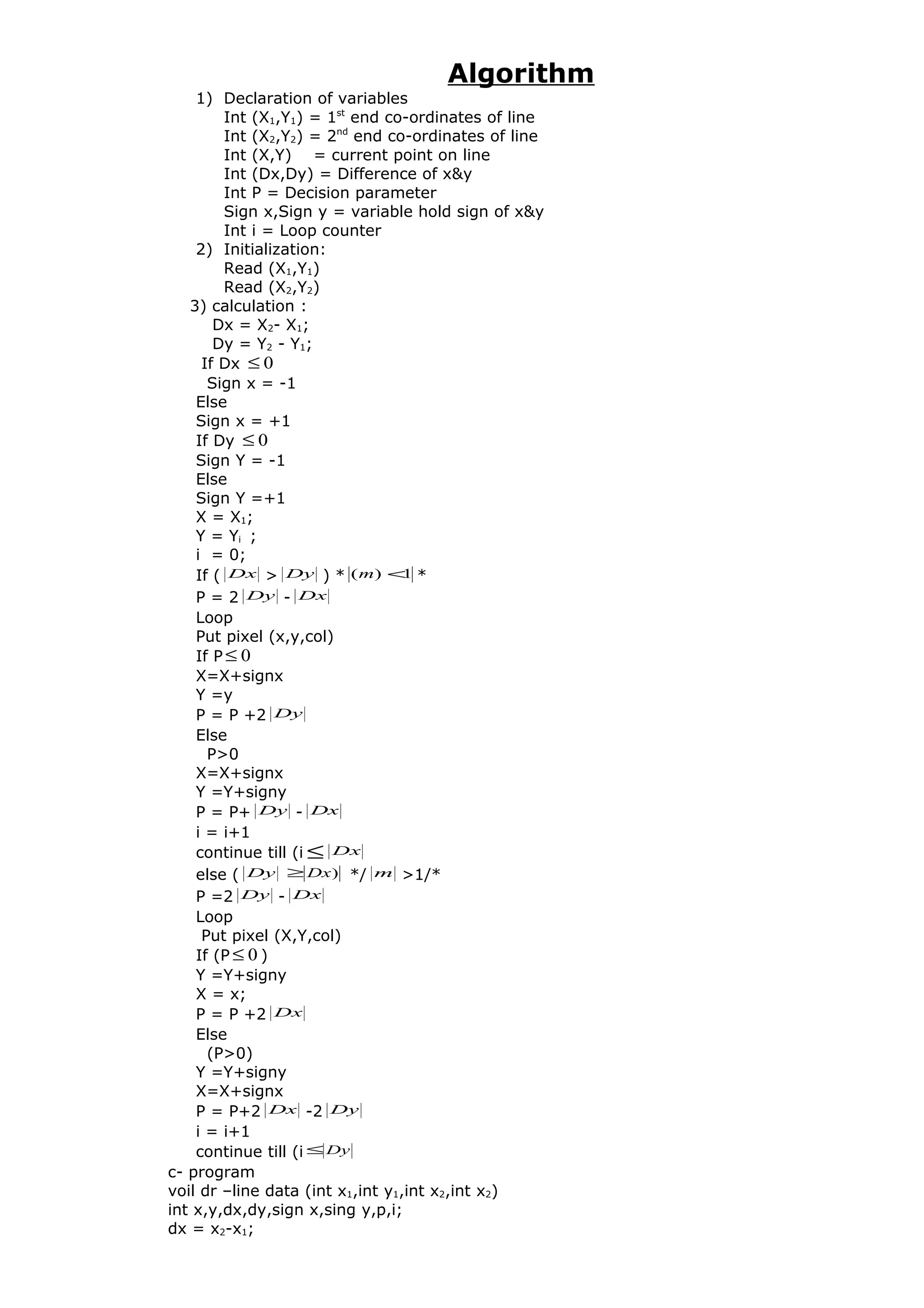

![As m<1

xi+1 = xi + 1

Yi+1 = Yi or Yi+1

If (d1) > (d2)

Yi+1 = Yi

If (d1) < (d2)

Yi+1 = Yi + 1

{ If (d1-d2}<0

Yi+1 = Yi

If (d1-d2}>0

Yi+1 = Yi + 1}

d1 = Y - Yi

d2 = Yi + 1 - Y

(d1 – d2) = Y - Yi – ( Yi + 1) + Y

=2Y – 2Yi – 1

Y= mX + C

X= Xi + 1

(d1 – d2) = 2[m(Xi + 1) + C ] – 2Yi 1

=2mXi – 2Yi + 2m + 2C + 1

(d1 – d2) = 2mXi – 2Yi + K

m = dy/dx

dX (d1 – d2) = 2dY Xi – 2 Yi dX + K dX

since dX be the d1 – d2 will be the same as sign of dX (d1 – d2).

Hence dX (d1 – d2) can be taken as a decision parameter co-ordiante of (Yi +

1)

dX (d1 – d2) = Pi

Pi = 2 dY Xi – 2 Yi dX + K

{If Pi < 0

xi+1 = Xi + 1

Yi+1 = Yi

If Pi > 0

Xi+1 = Xi + 1

Yi+1 = Yi + 1}

Similarly decision variables base on (i+1)th

point

Pi+1 = 2 dY Xi+1 – 2 dX Yi+1 + K

(Pi+1 – P1) = 2 dY (Xi+1 –Xi) – 2 dX (Yi+1 – Yi)

Pi+1 = Pi + 2 dY (Xi+1 –Xi) – 2 dX (Yi+1 – Yi)_____________1

If Pi < 0

xi+1 = Xi + 1

Yi+1 = Yi

Pi = Pi + 2 dY (Xi +1 –Xi) – 2 dX (Yi – Yi)

Pi = Pi +2dY

If Pi>0

xi+1 = Xi + 1

Yi+1 = Yi + 1

Pi = Pi + 2 dY (Xi +1 –Xi) – 2 dX (Yi + 1 – Yi)

Pi = Pi +2dY – 2dX

For Ist

point,](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-16-2048.jpg)

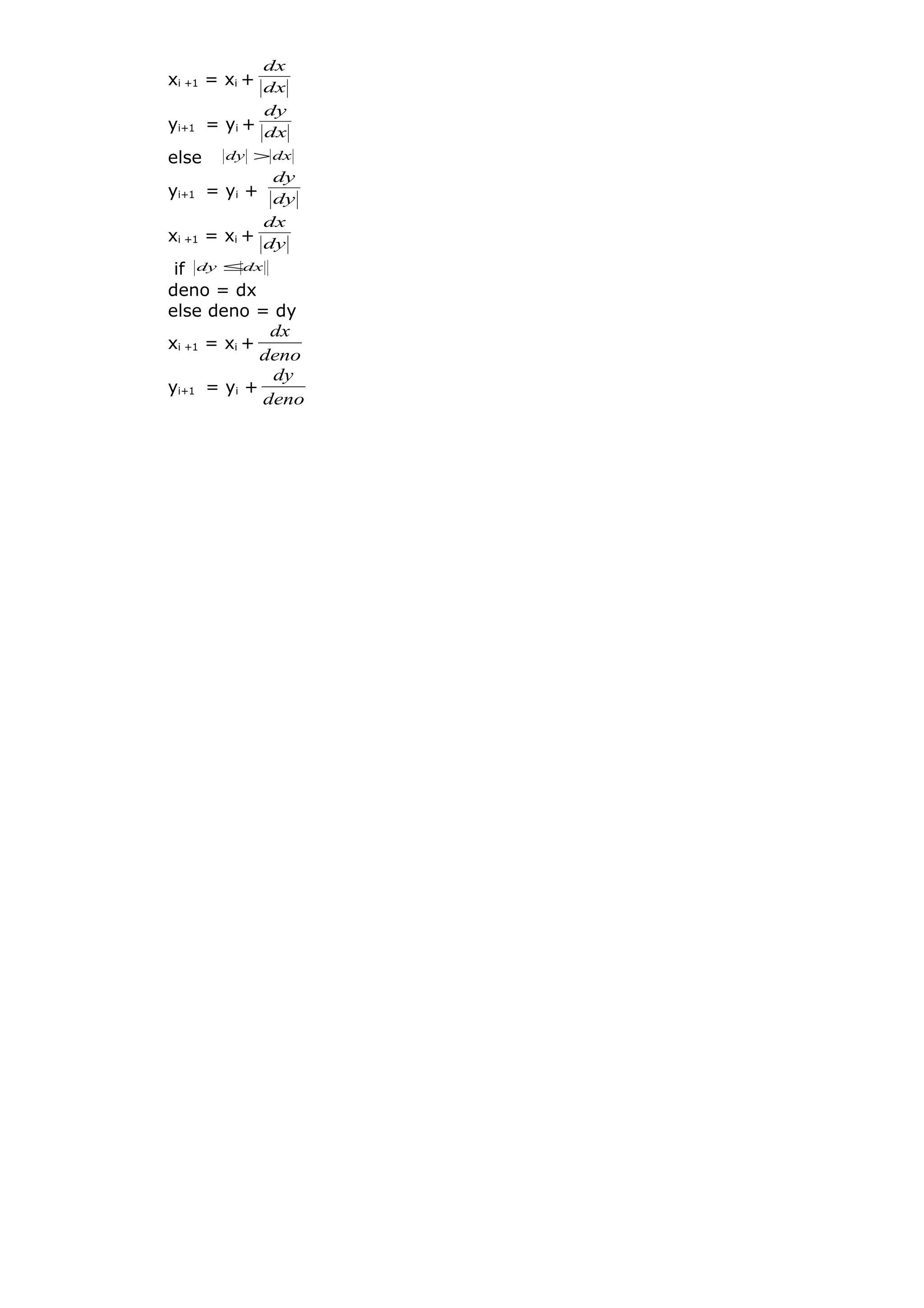

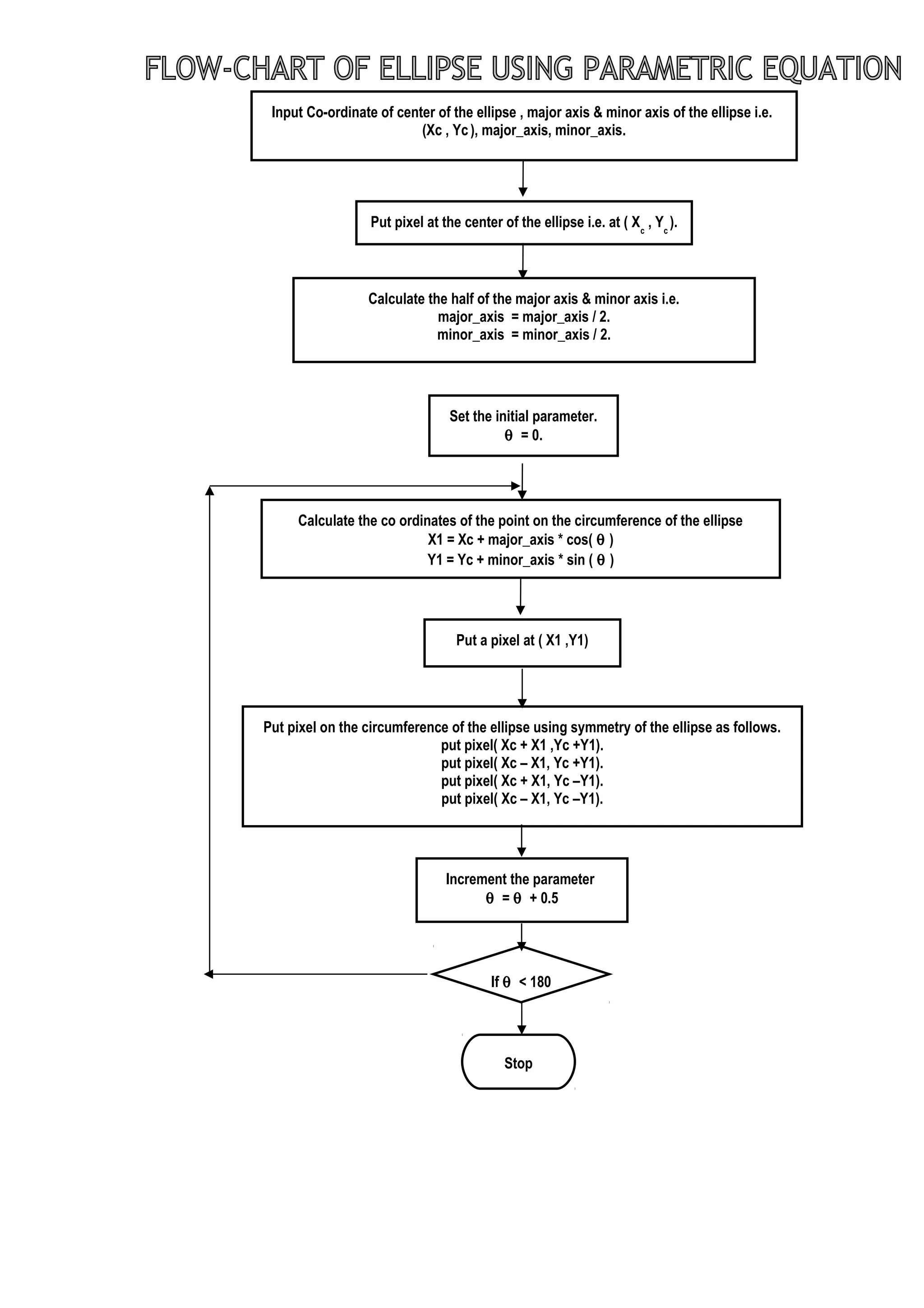

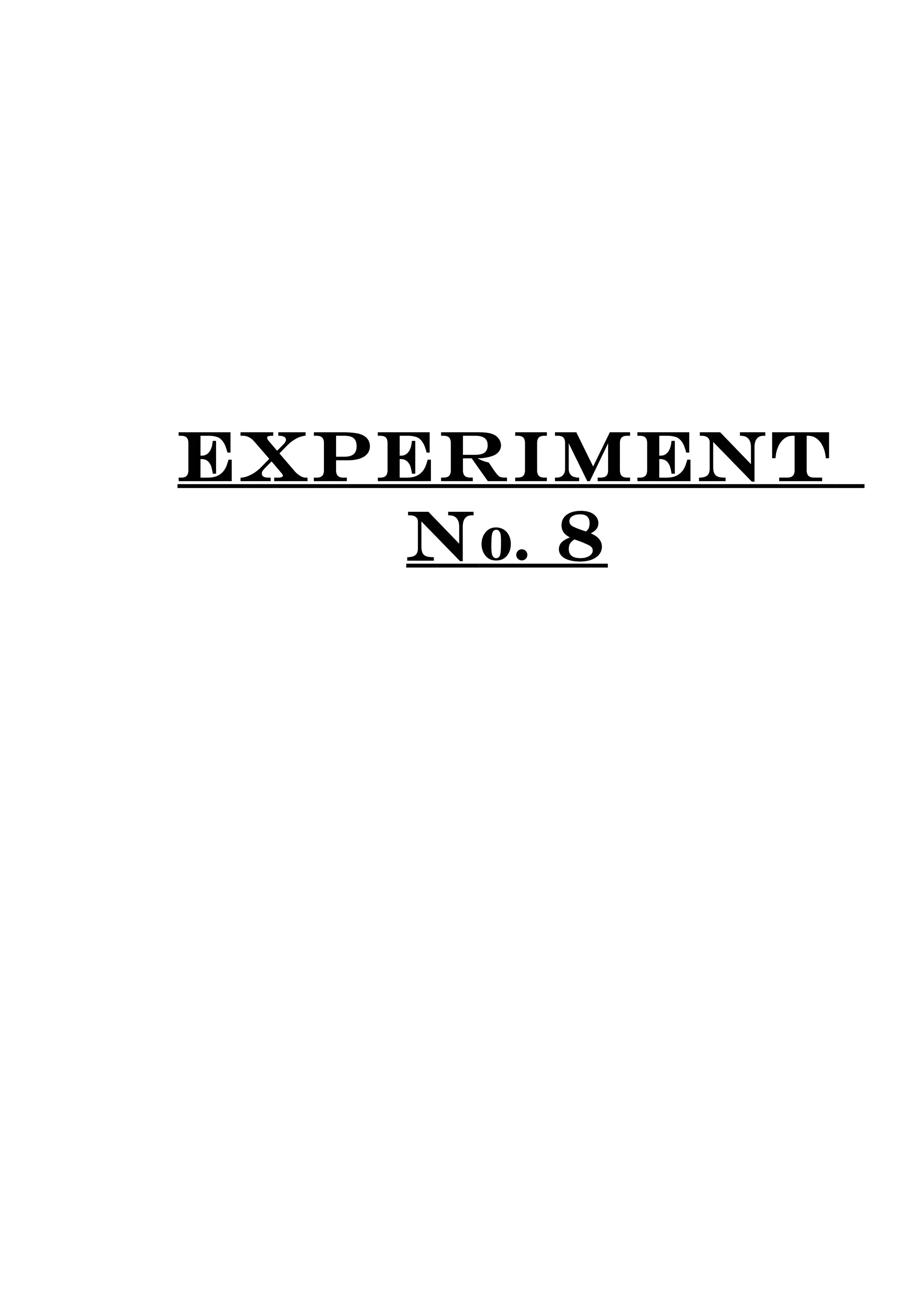

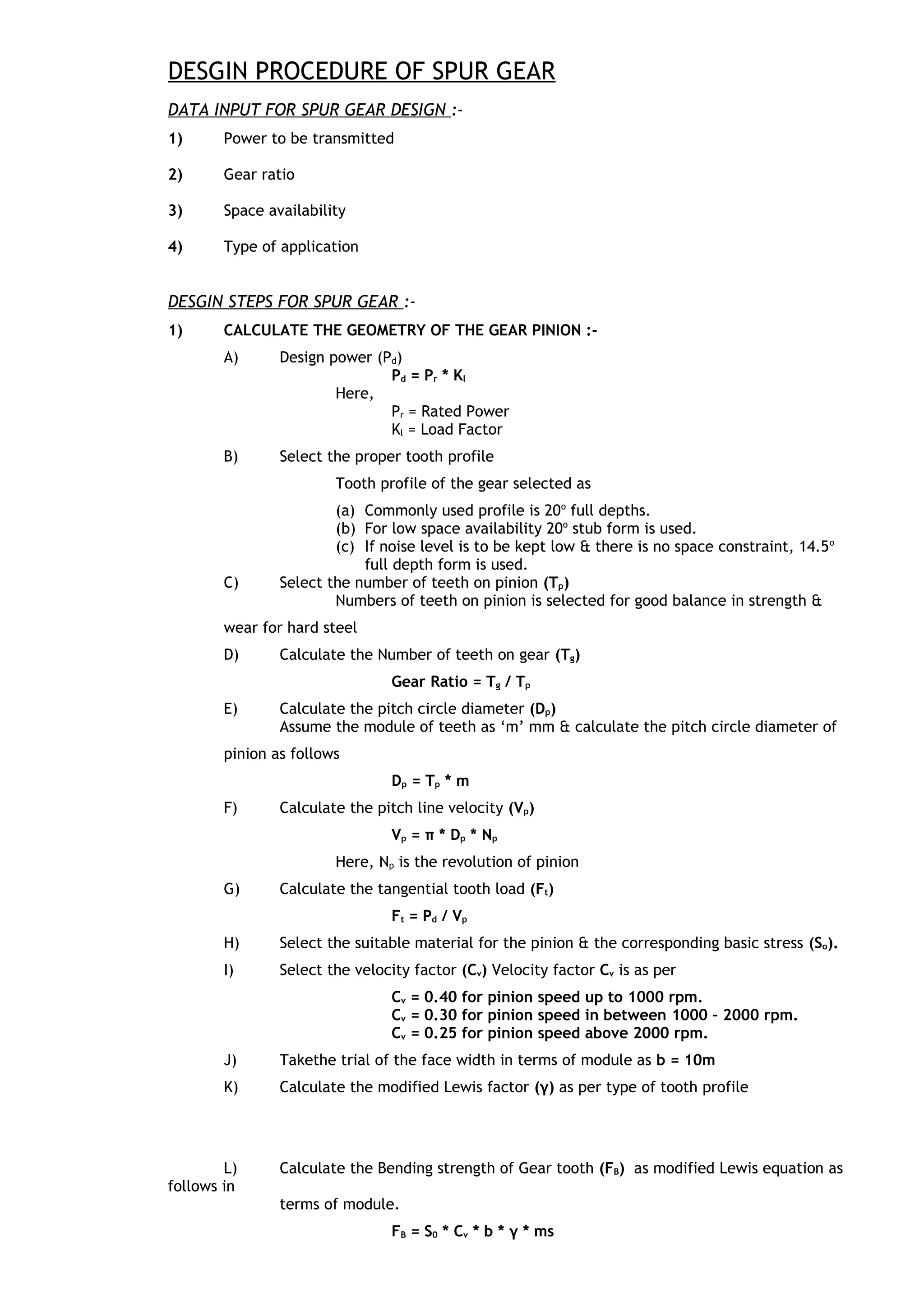

![Name of Experiment : Generation of Circle using

Parametric Bresenham’s Principle (Derivation,

Algorithm, Flow Chart, C-Programme and its Output)

CIRCLE USING BRESENHAM’S PRINCIPLE

DERIVATION: Mid point Algorithm for Generation of Circle Using

Bresenham’s Principle.

As m <1

Xi+1 = Xi +1

Yi+1 = Yi or Yi -1

Mid point m (Xm,Ym) = (Xi+1 ,Yi – ½)

If mid point inside the circle

Yi+1 = Yi

Out side the circle

Yi+1 = Yi - 1

Equation of circle = X2

+Y2

= R2

X2

+ Y2

– R2

= 0------I

Substitute the Co-ordinates of the mid point in Equation –1

Pi = Xm

2

+ Ym

2

– R2

If Pi

≤ 0

Xi+1 = Xi +1 (Inside)

Yi = Yi

Else

Pi > 0

Xi+1 = Xi +1

Yi+1 = Yi - 1 (Outside)

Pi = (Xi +1)2

+ (Yi – ½)2

– R2

= Xi

2

+ 2Xi +1 + Yi

2

– Yi + ¼ - R2

Pi = Xi

2

+ 2Xi + Yi

2

– Yi +[ 1 +¼ - R2

]

Pi = Xi

2

+ 2Xi + Yi

2

– Yi + K--------- II

(0,0) xi

xi +1

R

0,0

Radius

Outside Point

Mid point m (Xm

,Ym

) = (Xi+1

,Yi

– ½)

Inside Point

1

2

Slope less than 1

2-Slope greater than 1

yi

yi-1](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-20-2048.jpg)

![Where

K = 1 +¼ - R2

.

. . Decision based Variable based on (i+1)th

point

Pi+1 = (Xi +1)2

+ 2(Xi +1) +( Yi+1 ) - Yi+1 +K----III

Subs tract III-II

Pi+1 - Pi = [(Xi +1)2

- Xi

2

] + 2 [(Xi +1) - Xi] + [Yi+1

2

] – [Yi+1 - Yi]

Pi+1 = Pi + --------------------------------IV

If Pi ≤ 0

Xi +1 = Xi +1

Yi+1 = Yi

Substitute in Equation IV ,We get

Pi+1 = Pi +[(Xi +1)2

- Xi

2

] + 2 (Xi +1 - Xi) + Yi

2

- Yi

2

] – [Yi - Yi]

= Pi + [ Xi

2

+ 2Xi +1- Xi

2

+2]

= Pi +2Xi +1+2

Pi+1 = Pi +2Xi + 3------------------------V

If P > 0

Xi +1 = Xi +1

Yi+1 = Yi - 1

Substitute in Equation IV,We get

Pi+1= Pi+[(Xi +1)2

- Xi

2

] + 2 [(Xi +1 - Xi)] + [(Yi - 1)2

- Yi

2

)]- [Yi -1- Yi]

= Pi+[ Xi

2

+ 2Xi +1- Xi

2

+2]+[ Yi

2

- 2 Yi +1- Yi

2

]+1

= Pi+[2Xi+3] + [-2Yi +2]

Pi+1= Pi+2Xi -2 Yi +5

For finding Ist

decision variable point (0,R)

Xi=0 , Yi = R

Pi = Xm

2

+ Ym

2

– R2

=(Xi +1)2

+ (Yi – ½)2

– R2

= (0+1)2

+ (R-1/2)2

– R2

= 1 + R2

– R +1/4 – R2

P = 5/4 – R

P ≈ 1-R

Circle with Centre (Xc,Yc)

X = X + Xc

Y = Y + Yc

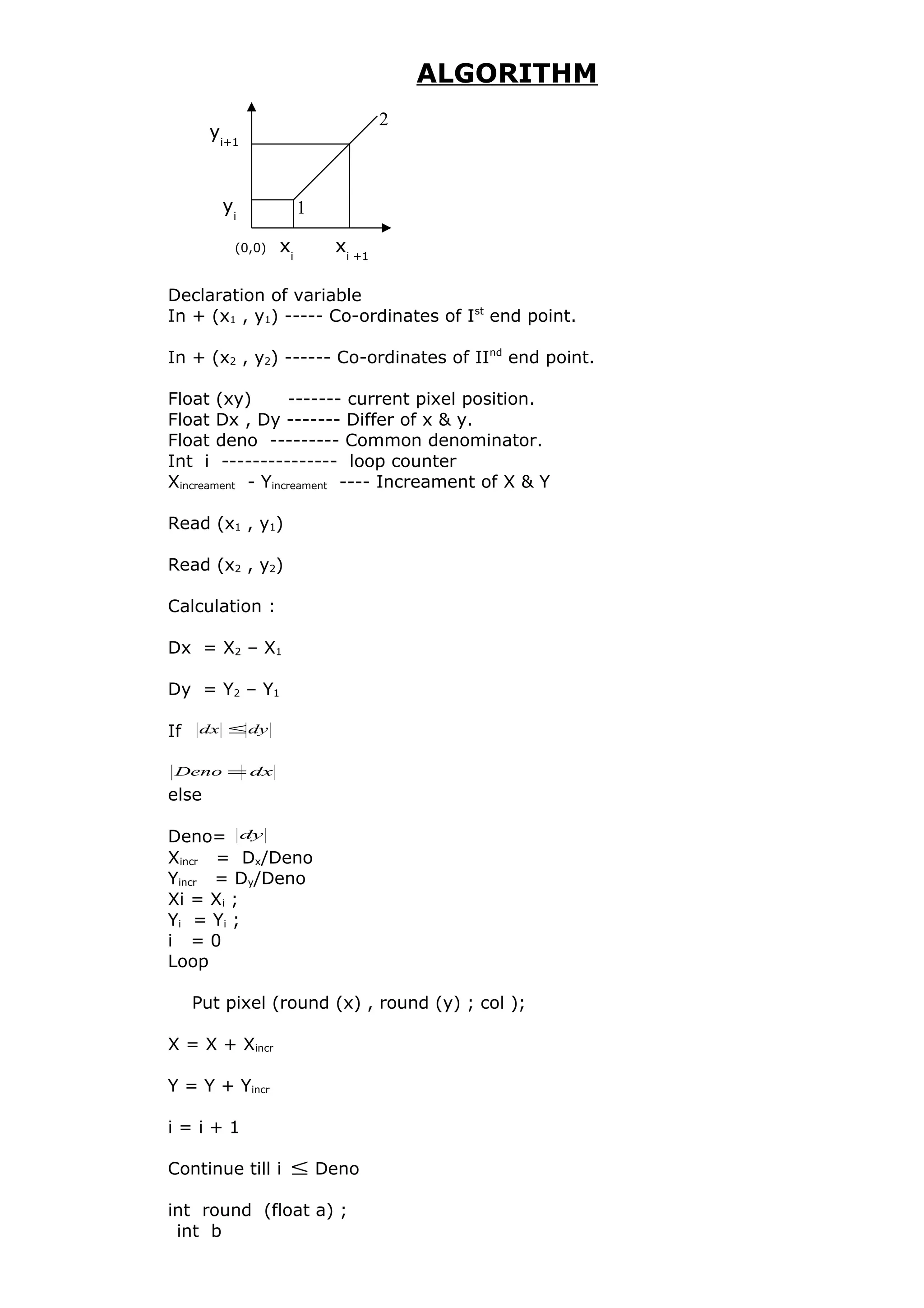

ALGORITHM

1) Declaration of variables:

Int (Xc,Yc)- Co-ordinate of Centre of circle

Int R – Radius of Circle](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-21-2048.jpg)

![EQUATION OF CIRCLE:

SUB CO-ORDINATE OF MID POINT

Pi = X +Y -

If PI < 0

Xi +1 = Xi +1

Yi = Y

Else Pi > 0

Xi +1 = Xi +Y

Yi = 1

Pi = + -

+ 2Xi + 1 + - Yi + ¼ -

Pi = + 2Xi + 1 + - Yi + [ 1+ ¼ - ]

Pi = + 2Xi + 1 + - Yi + K

Decision base variable k

Pi+1 = + 2 + ( ) – + K

Pi +1 – P1 = - ( ] + 2(Xi+1 - Xi)+ – ] + ( Yi+1 - Yi )

Pi+1 = Pi + - ( ] + 2(Xi+1 - Xi)+ – ] + ( Yi+1 - Yi )

If Pi < 0

=](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-27-2048.jpg)

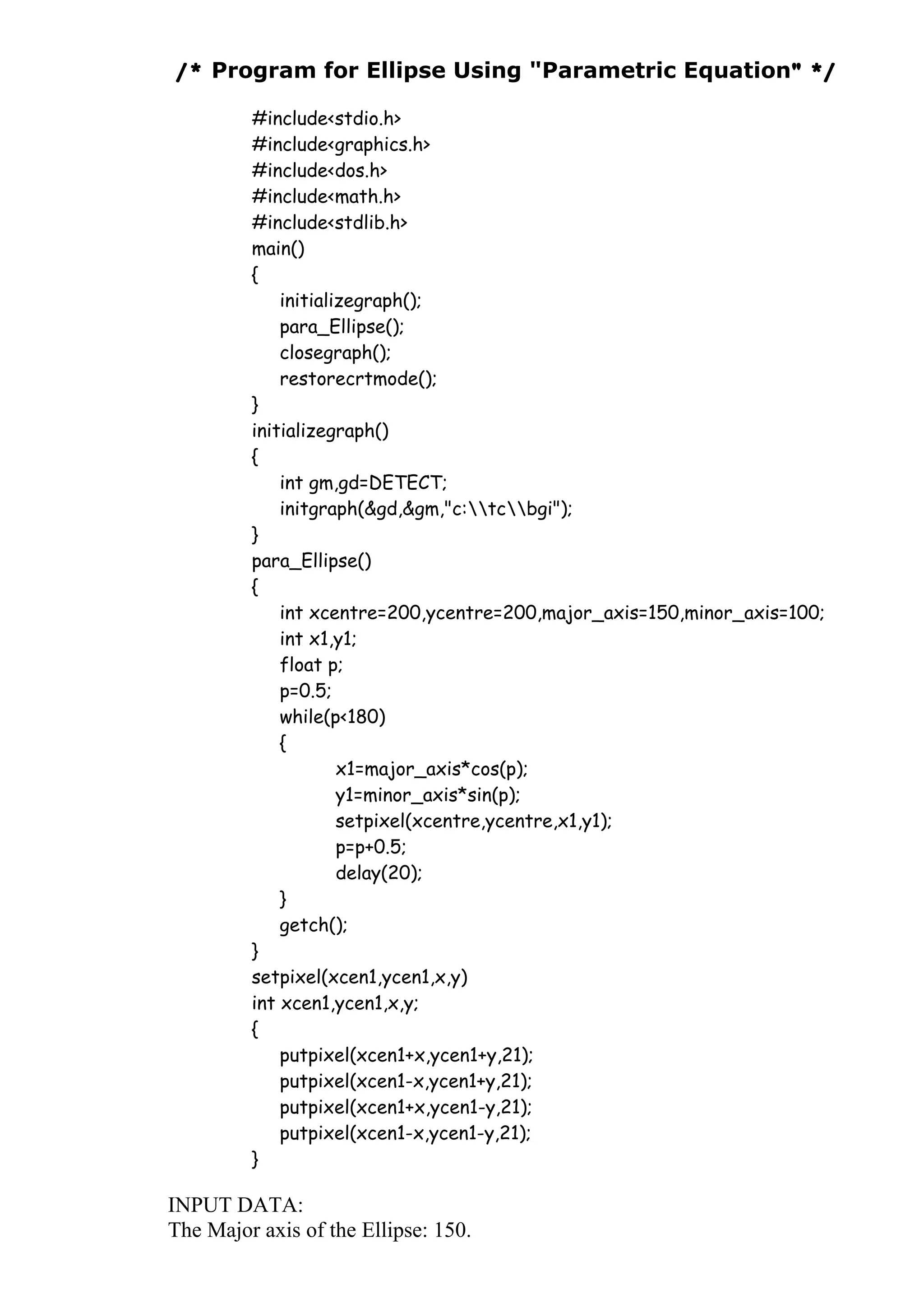

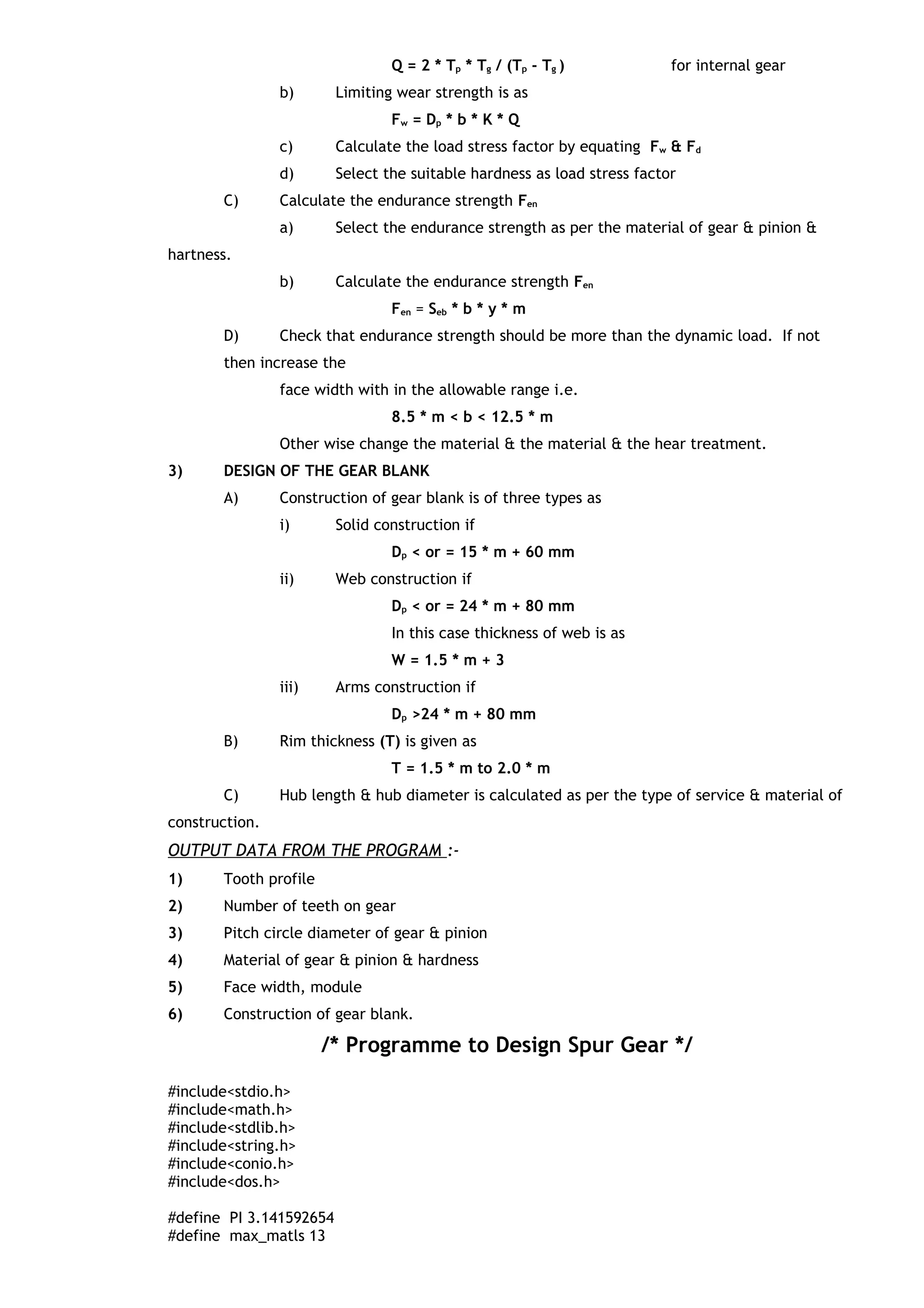

![Decision Variable

Pi = Ry2

x2

+ Rx2

y2

– Rx2

Ry2

Pi = Ry2

xm2

+ Rx2

Ym2

- Rx2

y2

Pi =Ry2

(Xi +1)2

+ Rx2

(Yi – ½)2

- Rx2

Ry2

Pi =Ry2

(Xi

2

+ 2Xi +2) + Rx2

(Yi

2

– Yi +1/4) – Rx2 Ry2

Pi =Ry2

(Xi

2

+ 2Xi ) + Rx2

(Yi

2

– Yi ) + [Ry2

+1 +

4

2Rx

- Rx2

Ry2

]

Pi =Ry2

(Xi

2

+ 2Xi ) + Rx2

(Yi

2

– Yi ) +K-------I

Where K= Ry2

+1 +

4

2Rx

- Rx2

Ry2

+1

Pi+1 = Ry2

( Xi+1

2

+2 Xi+1) + Rx2

(Yi+1

2

- Yi+1) +K---II

Sub Equation II & I

Pi+1 = Pi+ Ry2

{( Xi+1

2

- Xi

2

) + 2(Xi+1 - Xi)}

+ Rx2

{(Yi+1

2

- Yi

2

) – (Yi+1- Yi)}

If Pi 0≤ (midpoint inside)

Xi+1 = Xi+1

Yi+1 = Yi

Pi+1 = Pi+ Ry2

{( Xi+1

2

- Xi

2

) + 2(Xi+1 - Xi)}

+ Rx2

{(Yi

2

- Yi

2

) – (Yi- Yi)}

=Pi+ Ry2

{( Xi

2

+ 2Xi +1) +2}+ Rx2

{0}

Pi+1 = Pi+ Ry2

(2Xi +3)

If Pi > 0 (midpoint outside)

Xi+1 = Xi+1

Yi+1 = Yi-1

Pi+1 =Pi+ Ry2

{( Xi+1

2

- Xi

2

)+2(Xi+1 - Xi)}+Rx2

{( Yi-1)2

- Yi

2

]-[ Yi -1- Yi]

=Pi+ Ry2

{( Xi

2

+ 2Xi +1) +2}+ Rx2

{ Yi

2

-2Yi+1- Yi

2

]-[-1]

Pi+1 =Pi+ Ry2

[2Xi +3]+ Rx2

[-2Yi+2]

First Decision Variable

Xi = 0; Yi=Ry

Substitute in Equation I

Pi= Ry2

(Xi

2

+ 2Xi) + Rx2

(Yi

2

- Yi)+ Ry2

4

2Rx

-Rx2

-Rx2

Ry2

= Ry2

(0) + Rx2

(Ry2

- Ry)+ Ry2

+

4

2Rx

- Rx2

Ry2

=Rx2

Ry2

- Rx2

Ry+ Ry2

+

4

2Rx

- Rx2

Ry2

= Ry2

- Rx2

(Ry-1/4)

P ≈ Ry2

- Rx2

Ry2

ALGORITHM

1) Declaration of Variable

Int (Xc

,Yc

) --- centre of ellipse

Int (x,y) ----Current position of x&y

(0,0) xi

xi +1

R

0,0

Outside Point

Mid point m (Xm

,Ym

) = (Xi+1

,Yi

– ½)

Inside Point

1

2

1-Slope less than 1

2-Slope greater than 1](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-32-2048.jpg)

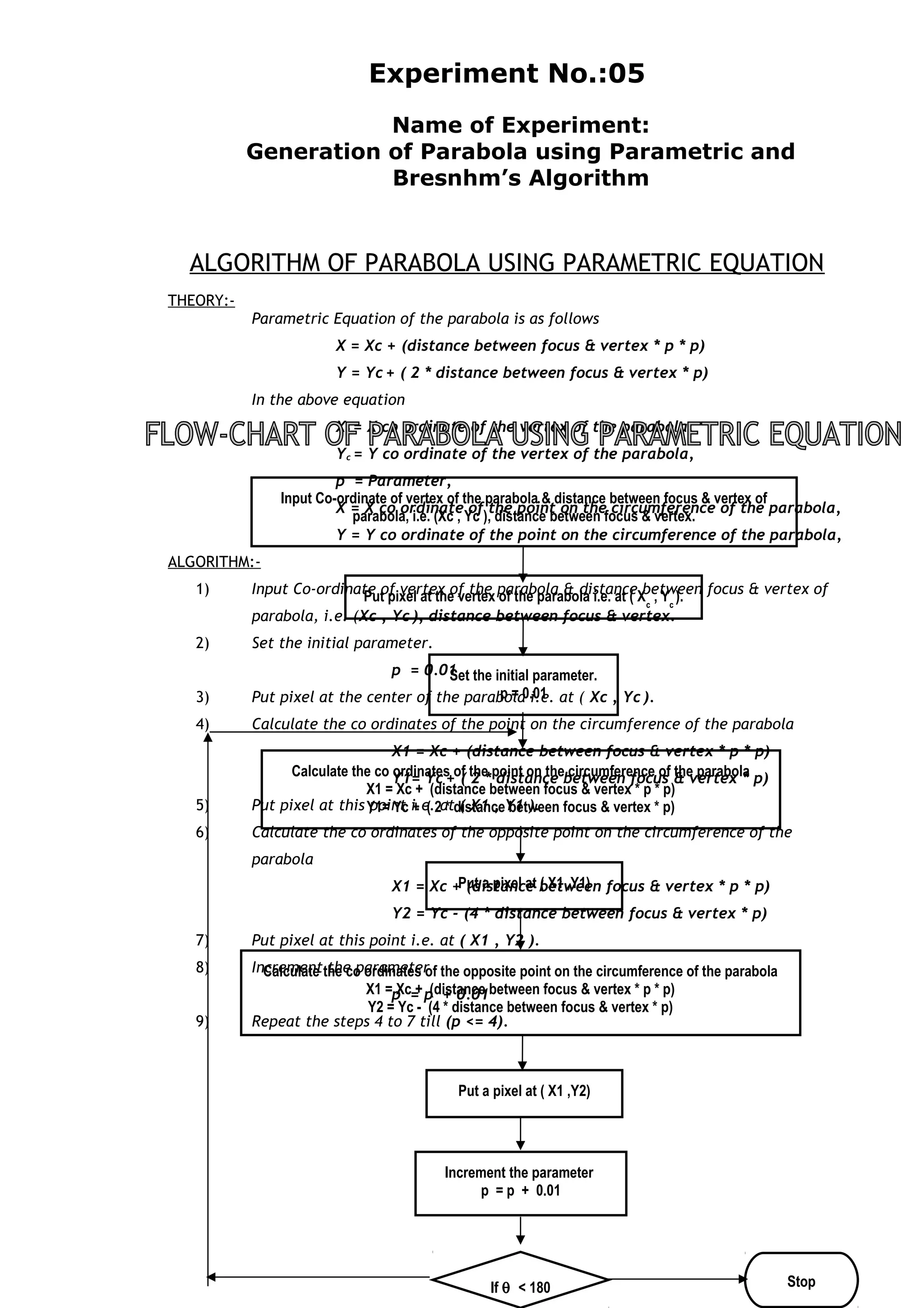

![Derivation of hyperbola

xy = k

dy = -k

dx x^2

-k = -k

x^2

x^2= k

-1< dy < 0

dx

xm= xi +1

ym= yi – y2 xy-x=0

P1 = xm ym = k= 0

P1 = (xi +1) (yi – y) ------------ 1

= xi yi - xi + yi - y2 – k

2

Pi+1 = xi +1, yi + 1- xi +1 + yi + 1 l/2 - k ---------- II

Pi+1 = [(xi +1, yi + 1)- xi yi ] –l/2 [xi +1- xi] + [(yi + 1- yi )]

= RY^2 (xi^2 +2xi + 1) + Rx^2 (yi^2 - yi +l/2 )- Rx^2 Ry^2

= RY^2 (xi^2 +2xi) + Rx^2 (yi^2 - yi)- (Ry^2 Rx^2-Rx^2 Ry^2)

4

Pi = RY^2 (xi^2 +2xi) + Rx^2 (yi^2 - yi)+k ----- I

Pi = RY^2 [ (xi+1 )^2 +2(xi +1)]+ Rx^2[ (yi+1)- yi+1]+k------ II

Pi+1 = Pi+ RY^2[(xi+1 )^2- xi ]+ 2 Rx^2[xi+1 - xi]+ Rx^2[ (yi^2+ yi^2)– (yi+1 - yi)]

If P< 0

xi+1 =xi+1

yi+1 - yi-1

Pi+1 = Pi+ RY^2[(2x+3) ]

If P> 0

xi+1 =xi+1

yi+1 = yi-1

Pi+1 = Pi+ RY^2[(2x+3) ]+ Rx^2[(-xy+2) ]

For first point on hyperbola

xi+ -0

yi= R

P= RY^2[(xi+1 )^2 ]+ 2 Rx^2[yi- l/2]-Rx^2 RY^2

xi+1 =xi+1

yi+1 = yi

Pi+1 = Pi+ [(xi+1 ) yi - xi yi ]-l/2 [xi+1 - xi]+ [ (yi- yi)]

= Pi+ [(xiyi + yi - x yi]- l/2

Pi+1 = Pi+ xi yi –l

If P> 0

xi+1 =xi+1](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-43-2048.jpg)

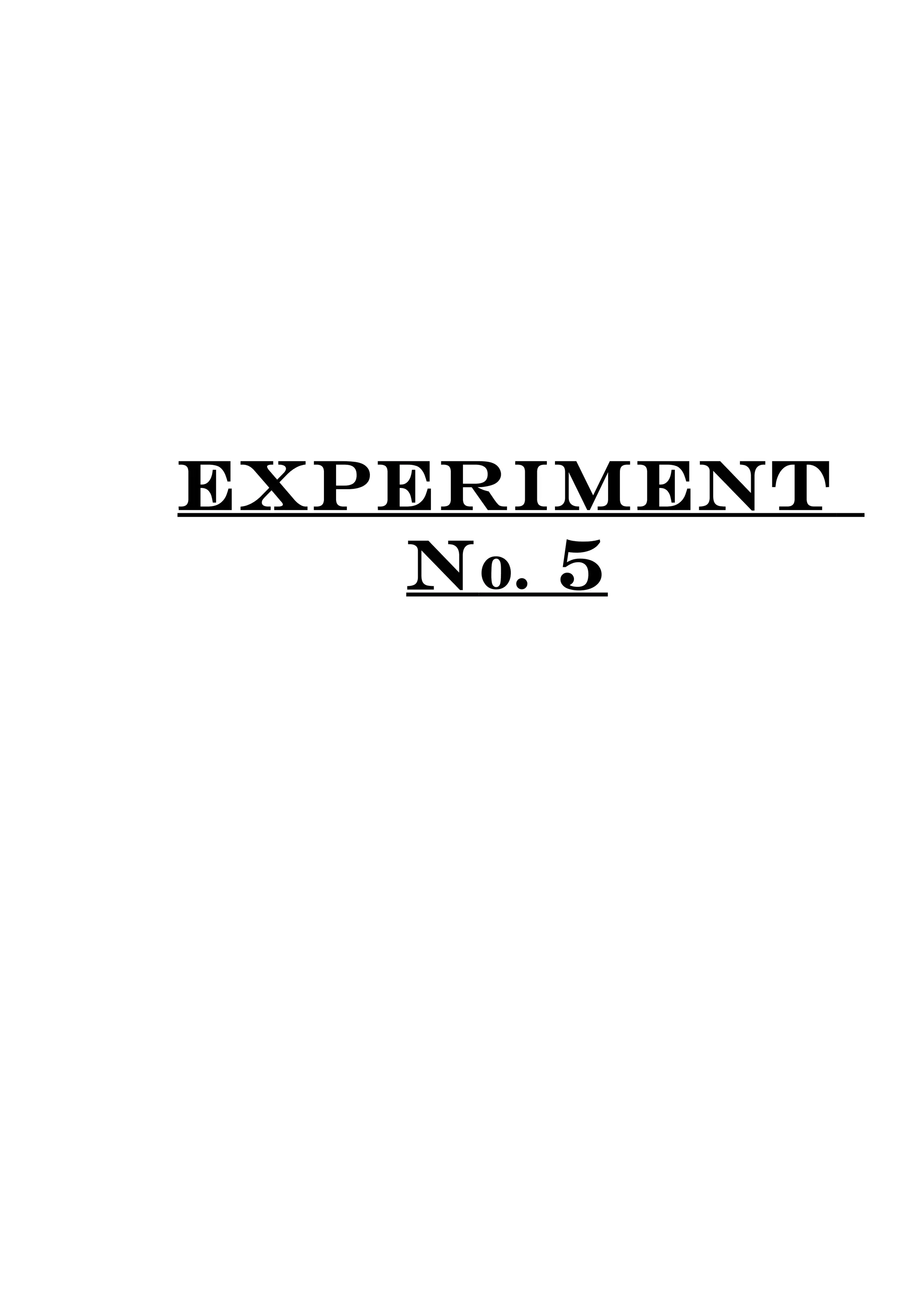

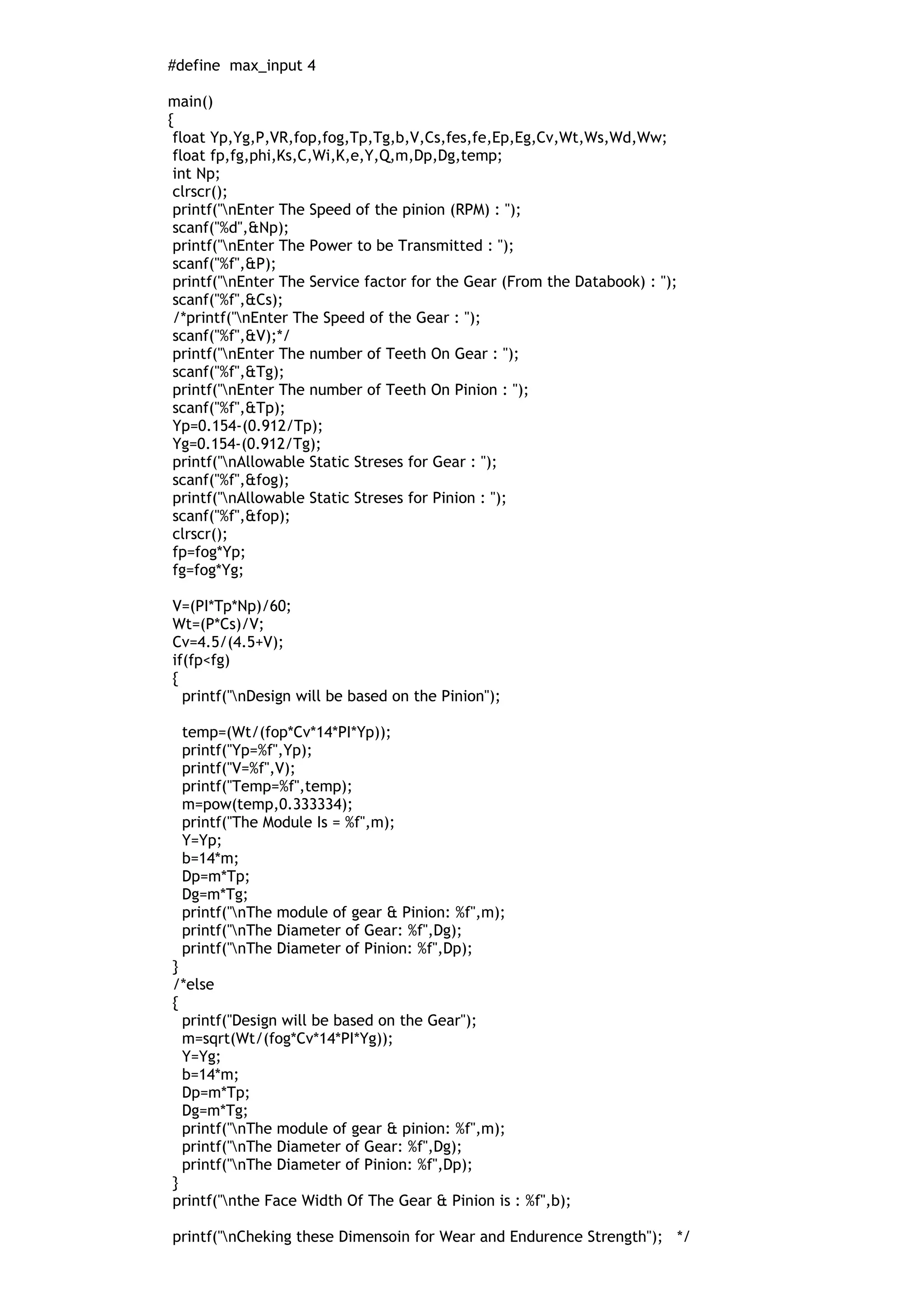

![Experiment No.:06

Name of Experiment:

Generation of Synthetic Curves (Bezier and B-Spline)

ALGORITHM FOR B-SPLINE CURVES

ALGORITHM: -

1) Initialization of all the required parameters.

2) Enter the co-ordinates of four control point Px(4) and Py(4).

3) For four control points degree (n) is three.

4) Calculate the knot vector as:

0 j<k

Uj = j-k+1 k j n

n-k+2 j>n

where,

0 j n +k

for the range of u,

0 u n – k + 2

5) Calculate the B-spline function for the four control points as

Ni,k(u) = (u-uj) Ni,k-1(u)/(ui,k+1-ui) + (ui+k-u) Ni+1,k-1(u)/(ui+k-ui-1)

Where,

Ni,j = 1, ui u ui+1

O, otherwise

Considering 0/0 = 0 if the denominator in above equation becomes

zero

6) Calculate the corresponding four control points on the B-Spline curve as

P(u)x = Px[0]*N0,4+Px[1]*N1,4+Px[2]*N2,4+Px[3]*N3,4 for 0 u 1

P(u)y = Py[0]*N0,4+Py[1]*N1,4+Py[2]*N2,4+Py[3]*N3,4 for 0 u 1

By incrementing u in small step.

7) Graphics Initilisation.

8) Plot the co-ordinates](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-52-2048.jpg)

![/* Program for "B-Spline" */

#include<math.h>

#include<graphics.h>

#include<stdlib.h>

#include<stdio.h>

#include<conio.h>

void main(void)

{

int i,j,n,m,m1,k,x,s,k1;

float Umax,Umin,u,Uk[10],N[20][20],px[4],py[4]={0},X[4]={0},Y[4]={0};

float num1=0,num2=0,deno1=0,deno2=0,Ax[4]={0},Ay[4]={0},sumX=0,sumY=0;

int gdriver = DETECT, gmode, errorcode;

clrscr();

printf("nEnter the number of control point ");

scanf("%d",&k);

printf("nEnter the coordinate of control point ");

for(i=0;i<=k-1;i++)

{

scanf("%f",&px[i]);

scanf("%f",&py[i]);

}

k1=k;

n=k-1;

Umin=0;

Umax=n-k+2;

s=n+k;

for(j=0;j<=n+k;j++)

{

if(j<k)

Uk[j]=0;

else

{

if(j>=k&&j<=n)

Uk[j]=j-k+1;

else

{

if(j>n)

Uk[j]=n-k+2;

}

}

}

for(i=0;i<=n;i++)

{

for(k=1;k<=n;k++)

{

if((i+k)>s)

continue;

else

{

if(Uk[i+k-1]-Uk[i]==0&&Uk[i+k]-Uk[i+1]==0)

{

N[i][k]=0;

}

}

}

}

for(i=0;i<=n;i++)

{

if(u>=Uk[i]||u<=Uk[i+1])

N[i][1]=1;

else

N[i][1]=0;

}](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-53-2048.jpg)

![initgraph(&gdriver, &gmode, "");

errorcode = graphresult();

if (errorcode != grOk) /* an error occurred */

{

printf("Graphics error: %sn", grapherrormsg(errorcode));

printf("Press any key to halt:");

getch();

exit(1); /* terminate with an error code */

}

for(u=0;u<=1;u=u+0.01)

{

for(k=2;k<=(n+k)-1;i++)

{

for(i=0;i<=(n+k)-1;i++)

{if((i+k)>s)

break;

else

{

x=i+k-1;

deno1=(Uk[x]-Uk[i]);

deno2=(Uk[i+k]-Uk[i+1]);

num1=((u-Uk[i])*(N[i][k-1]));

num2=((Uk[i+k]-u)*(N[i+1][k-1]));

if(deno1==0)

{num1=0;

}

if(deno2==0)

{

num2=0;

}

N[i][k]=(num1/deno1)+(num2/deno2);

}

}

}

for(m1=0;m1<4;m1++)

{

Ax[m1]=px[m1]*N[m1][k1];

Ay[m1]=py[m1]*N[m1][k1];

sumX=sumX+Ax[m1];

sumY=sumY+Ay[m1];

}

putpixel(50*sumX,50*sumY,3);

sumX=0;

sumY=0;

}

getch();

closegraph();

getch();

}](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-54-2048.jpg)

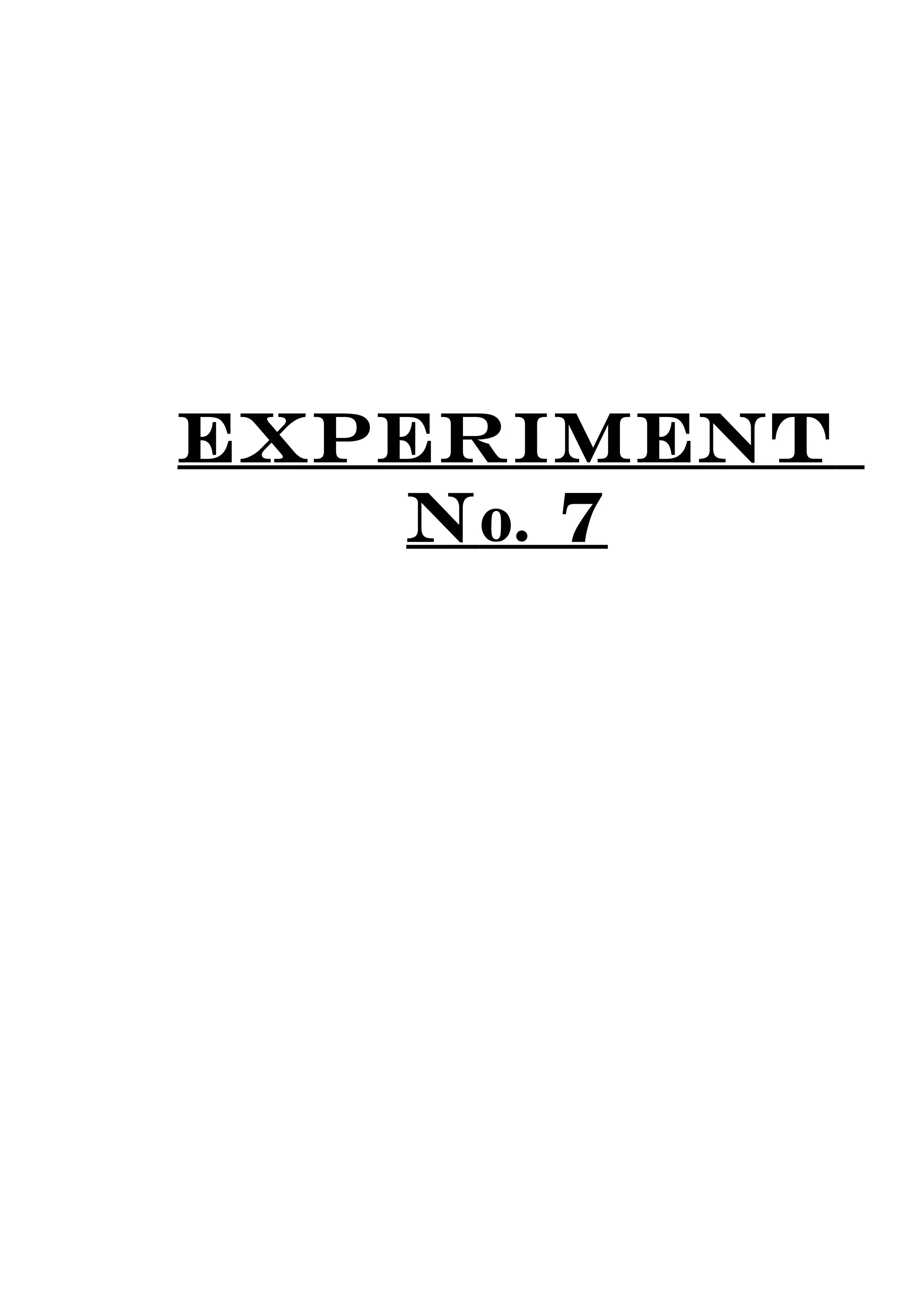

![Experiment No.:07

Name of Experiment:

Two Dimensional Transformation (Any Two Numerical)

Q.1: A triangle with vertices at A(0,0),B(8,0),C(0,8) is scaled by

1.2 units in X direction. It is translated by 3.5 units in Y direction

and two units X direction. Find the final position of the triangle.

Show the total transformation on graph paper stepwise.

Ans. The original position of the given ∆ ABC is shown in graph paper.

The final transformation is given as,

P’ = P.TT

Where TT = Total transformation

TT = S.T.

P =

180

108

100

S =

100

00

00

Sy

Sx

=

100

010

002.1

T =

0

010

001

tytx

T =

15.32

010

001

TT = [ ]S X [ ]T

=

100

010

002.1

.

15.32

010

001

TT =

15.30

010

002.1

P’ = [ ]P .[ TT]

=

180

108

100

15.32

010

002.1](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-56-2048.jpg)

![P’ =

15.112

15.36.11

15.32

The final position of triangle ABC is shown on graph paper.

Coordinates of ∆ A’B’C are;

A’ (2,3.5)

B’ (11.6,3.5)

C’ (2,11.5)

Q.2: Find the transformation which converts the fig. defined by

vertices

A(3,2),B(2,1) and C(4,1) into another figure which is defined by

Vertices A’(-3,-1),B(-4,-2) and C’(-2,-2).

Ans. Let [P’] – is final position of triangle A’B’C’

[P] - is initial position of triangle ABC

[G] – is transformation matrix.

Given data:

Final position of triangle is

A’(-3,-1)

B’(-4,-2)

C’(-2,-2)

Initial position of triangle is

A(3,2)

B(2,1)

C(4,1)

General expression for determining final position of object is

[P’] = [P] [G]

∴[G] = [P]-1

[P’]……………………………….(1)

Now

Final position [P’] =

−−

−−

−−

122

124

113

And initial position

[P]=

114

112

123

Inverse matrix [P] is given by following generalized equation

[P]-1

=

]det[

][int

P

PofAdjo

……………………….(2)](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-57-2048.jpg)

![Co-factor of [P] = -

12

23

14

23

14

12

12

13

14

13

14

12

11

12

11

12

11

11

−

−

=

−−

−−

−

111

511

220

When rows are converted into columns. Adjoint of [P] is determined

∴Adj[P] =

−−

−−

−

111

511

220

Similarly determinant of [P] is determined as det [P] = 3(1-1)-2(2-4)+(2-

4)

= 2

From equation (2)

[P]-1

=

]det[

][int

P

PofAdjo

=

−−

−−

−

2

1

2

5

1

2

1

2

1

1

2

1

2

1

0

Thus, substituting values of [P]-1

in equation (1)

[G] =

−−

−−

−

2

1

2

5

1

2

1

2

1

1

2

1

2

1

0

−−

−−

−−

122

124

113

∴[G] =

−− 136

010

001

Check

[P’] = [P] [G]

=

114

112

123

−− 136

010

001](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-58-2048.jpg)

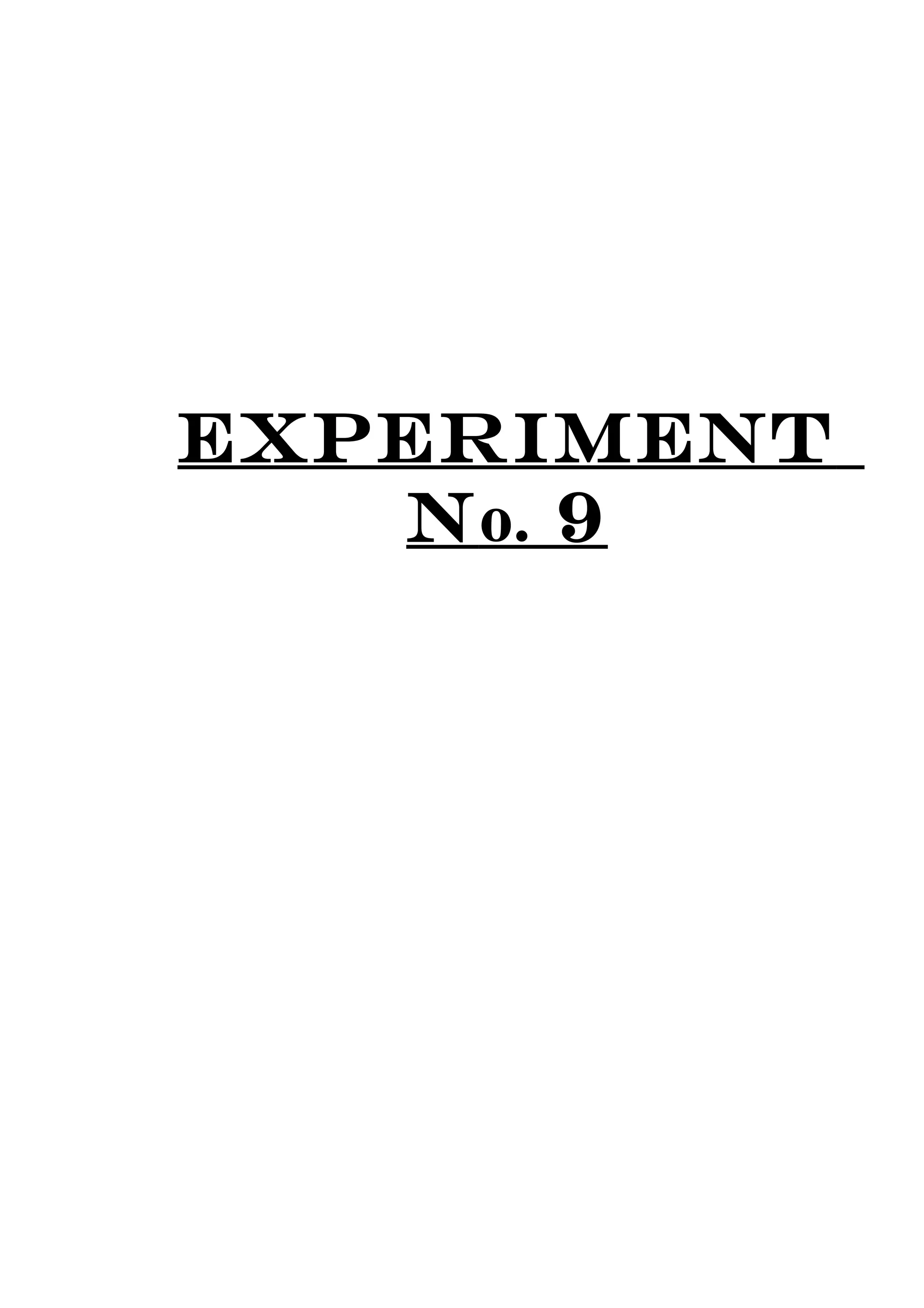

![Experiment No.:08

Name of Experiment:

Three Dimensional Transformation (Any Two Numerical)

Q.1: Consider a region defined by the position vectors

[ ]X =

1221

1222

1212

1211

D

C

B

A

Relative to the global XYZ axis system. It is rotated by +300

about the X’ axis parallel to X axis and passing through point

(1.5,1.5,1.5,1).Find the final transformation matrix and final

positions of the region.

Ans. The final transformation is carried out as follows.

[ ]'X =

1221

1222

1212

1211

4x4

Steps : (1) We will first translate the object so that rotation axis X’

coincide with the X axis.

(2) Perform rotation about the object so that 300

ccw, (θ = +300

)

(3) Again translate the object so that X’ moves to its original position.

∴ T1 =

1111

0100

0010

0001

tztytx

4x4

tx1 = -1.5, ty1 = -1.5, tz1 = -1.5

T1 =

−−− 15.15.15.1

0100

0010

0001

4x4

∴ Rx =

°°−

°°

1000

030cos30sin0

030sin30cos0

0001

4x4

∴ Rx =

−

1000

0866.05.0

05.866.00

0001

4x4](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-64-2048.jpg)

![T2 =

15.15.15.1

0100

0010

0001

4x4

∴ TT = [T1].[ Rx].[T2]

=

−−− 15.15.15.1

0100

0010

0001

x

−

1000

0866.05.0

05.866.00

0001

x

15.15.15.1

0100

0010

0001

∴ TT =

−−−

−

1049.2549.05.1

0866.05.00

05.866.00

0001

15.15.15.1

0100

0010

0001

TT =

−

−

1549.0951.00

0866.05.00

05.0866.00

0001

…..Final Transformation Matrix

4x4

Now we will find final positions of the region.

X’ = [X] [TT]

=

1221

1222

1212

1211

−

−

1549.0951.00

0866.05.00

05.0866.00

0001

4x4 4x4

X’ =

1183.2683.11

1183.2683.12

1683.1817.02

1683.1817.01

4x4

Numerical for Practical:

1. Determine the 4 X 4 transformation matrices for the rotation of 3-D

point in 3-D space.](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-65-2048.jpg)

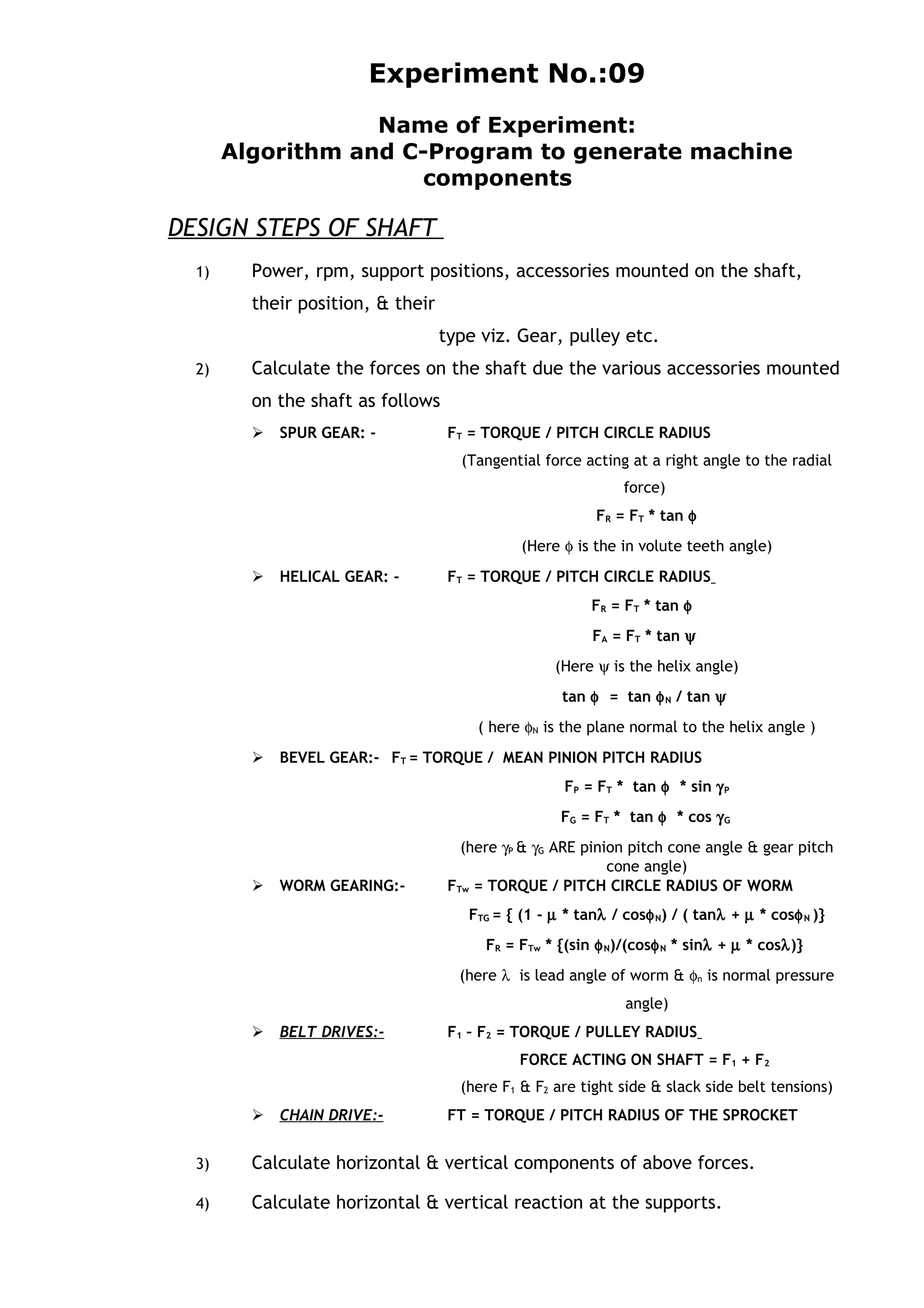

![/* PROGRAM OF DESIGN OF SHAFT */

#include<stdio.h>

#include<math.h>

#include<stdlib.h>

#include<string.h>

#include<conio.h>

#include<dos.h>

#define PI 3.141592654

#define max_matls 13

#define max_input 4

void main()

{

float Reaction(float,float,float,float,float);

float Diameter(long,long,float,float);

char matl[max_matls][15],matl_in[max_matls][15];

long T,P,M,Me,Te,x;

int i,j,Syt[max_matls]={0},Sut[max_matls]={0},Rho[max_matls]={0};

float Ss,Sd,Ss1,Sd1,x1,x2;

float l,l1,l2,l3,d,d1,d2,d3,d4,Km,Kt,RA,RD,WB,WC,MB,MC,N;

FILE*fp;

clrscr();

fflush(stdin);

printf("nEnter Power[W] : ");

scanf("%ld",&P);

printf("nEnter Speed of The Shaft [RPM] : ");

scanf("%f",&N);

printf("nEnter distance between Bearing and Gear [mm] : ");

scanf("%f",&l1);

printf("nEnter distance between Gear and Pulley [mm] : ");

scanf("%f",&l2);

printf("nEnter distance between Pulley and End Bearing [mm] : ");

scanf("%f",&l3);

printf("Enter the Load Acting on Gear [N] : ");

scanf("%f",&WB);

printf("Enter the Load Acting on Pulley [N] : ");

scanf("%f",&WC);

RD=Reaction(WB,WC,l1,l2,l3);

RA=WB+WC-RD;

MB=RD*(l2+l3);

MC=RD*l3;

if(MB>MC)

M=MB;

else

M=MC;

T=P*60/(2*PI*N);

printf("Enter Combined shock & Fatiuge Factor for Bending : ");

scanf("%f",&Km);

printf("Enter Combined shock & Fatiuge Factor for Torsion : ");

scanf("%f",&Kt);

x=(Km*M*Km*M)+(Kt*T*Kt*T);

Te=sqrt(x);

Me=0.5*(M+Te);

if((fp=fopen("sd1.dat","r"))==NULL)

{

printf("Unable to Openn");

printf("Sorry!!! Please Try Again");

getch();

exit(0);

}

else](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-69-2048.jpg)

![{

printf("nfile opened successfully!");

printf("nMaterialtSyttDensity");

for (i=0;i<=max_matls-1;i++)

{

fscanf(fp,"%s%d%d",&matl[i],&Syt[i],&Rho[i]);

printf("n%stt%dt%d",matl[i],Syt[i],Rho[i]);

}

for (i=0;i<=0;i++)

{

printf("nEnter Material No : ");

scanf("%s",&matl_in[i]);

for (j=0;j<=max_matls-1;j++)

{

if ((strcmp(matl_in[i],matl[j]))==0)

{

Ss=Syt[j]/2;

Sd=0.3*Syt[j];

break;

}

else

continue;

}

}

d=Diameter(Te,Me,Ss,Sd);

if(MB>MC)

{

d1=d;

d2=d+3;

d3=d2+3;

d4=d-5;

Ss1=(T*16)/(PI*d4*d4*d4);

if(Ss1<Ss)

printf("nDesign is Safe");

else

printf("Diameter for the Bearing Allocation is to be redesigned");

}

else

{

d2=d;

d1=d-3;

d3=d2+3;

d4=d-5;

Ss1=(T*16)/(PI*d1*d1*d1);

Sd1=(M*32)/(PI*d1*d1*d1);

if(Ss1<Ss||Sd1<Sd)

printf("nDesign is Safe");

else

printf("Diameter for the Bearing and Gear Allocation is to be redesigned");

}

printf("n--------------------------------------------------------");

printf("nRESULT: ");

printf("nSelected Material: %s ",matl_in[0]);

printf("Designed Diameters of Stepped Shaft are nd1= %fnd2= %fnd3= %fnd4=

%f",d1,d2,d3,d4);

}

getch();

fcloseall();

}

float Reaction(float WB,float WC,float l1,float l2,float l3)

{

float RD,l;](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-70-2048.jpg)

![#include<math.h>

#include<stdlib.h>

#include<stdio.h>

#include<conio.h>

#include<string.h>

#define PI 3.141592654

#define max_matls 5

#define max_input 4

void main()

{

float W,to,Z,ta,pmax,p,t,C,c,l,d,R,Ov,Od,K,cd1,u,k,Hg,Hd,V,A,S,m;

int i,j,N;

char matl[max_matls][25],matl_in[max_matls][25],Mtl;

float

visco[max_matls]={0},cd[max_matls]={0},ld[max_matls]={0},ZN_p[max_matls]={0};

FILE *fp;

clrscr();

fflush(stdin);

printf("nEnter load on journal (Newton) ");

scanf("%f",&W);

printf("nEnter speed of journal(rpm) ");

scanf("%d",&N);

printf("nEnter the ambient temp of oil(deg C) ");

scanf("%f",&ta);

printf("nEnter the maximum pressure of bearing(N/mm2) ");

scanf("%f",&pmax);

/*design starts*/

printf("nEnter the assumed dia of journal(mm) ");

scanf("%f",&d);

if((fp=fopen("Bdata.dat","r"))==NULL)

{

printf("Unable to Openn");

printf("Sorry!!! Please Try Again");

getch();

exit(0);

}

else

{

printf("nFile Opened Successfully!");

printf("nApplicationtViscositytZN/pttc/dtl/d");

for(i=0;i<=max_matls;i++)

{

fscanf(fp,"%s%f%f%f%f",&matl[i],&visco[i],&ZN_p[i],&cd[i],&ld[i]);

printf("n%stt%ft%ft%ft%f",matl[i],visco[i],ZN_p[i],cd[i],ld[i]);

}

for(i=0;i<=0;i++)

{

printf("nEnter Material No,%d : ", i+1);

scanf("%s",&matl_in[i]);

for (j=0;j<=max_matls-1;j++)

{](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-73-2048.jpg)

![if ((strcmp(matl_in[i],matl[j]))==0)

{

l=ld[j]*d;

p=W/(l*d);

Ov=(visco[j]*N)/p;

K=ZN_p[j]/3;

k=0.002; /*for l/d ratio of 0.75 to 2.8*/

u=(33*Ov/cd[j])/(pow(10,8)) +k;

break;

}

else

{

/*printf("nMaterial is not Present In The List");*/

continue;

}

}

}

}

if(p<pmax)

{

printf("nDimension l and d are Safe: ");

}

else

{

printf("n New Dimension of l and d are to be selected: ");

}

printf("nEnter the Operating Temp of Oil(deg C): ");

scanf("%f",&to);

printf("nBearing Modulus at Minimum Point of Friction ");

if(Ov>K)

{

printf("nBearing will Operate at Hydrodynamic Conditions");

}

else

{

printf("n Bearing will have Metal to Metal Contact");

}

V=(3.1428*d*N)/60000;

Hg=u*W*V;

printf("nEnter Heat Dissipation Coefficient from data book: ");

scanf("%f",&C);

A=l*d/(pow(10,6));

Hd=(C*A*(to-ta))/2;

printf("n Heat dissipation Hd= %f J/s",Hd);

printf("n Heat generated Hg= %f J/s",Hg);

printf("n A= %f m2",A);

if(Hg>Hd)

{

printf("nBearing is to be re-design by taking higher operating temperature(to) ");

printf("nor Bearing should be cooled artificially");

printf("nEnter specific heat of oil: ");](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-74-2048.jpg)

![/* Program to Design Flywheel */

#include<stdio.h>

#include<math.h>

#include<stdlib.h>

#include<string.h>

#include<conio.h>

#include<dos.h>

#define PI 3.141592654

#define max_matls 13

#define max_input 4

void main(void)

{

float m,t,b,rho,FS,Syt,Sd,DE,Cs,D,Rad,k;

char matl[max_matls][15],matl_in[max_matls][15];

float Rho[max_matls]={0};

int syt[max_matls]={0};

int N,i,j;

FILE *fp;

clrscr();

fflush(stdin);

printf("Enter The Speed of the Shaft (RPM) : ");

scanf("%d",&N);

/*printf("Enter the Ultimate Stress in Tension of Material Selected (N/m2) : ");

scanf("%f",&Syt);

printf("Enter the Density of Material Selected (kg/m3) : ");

scanf("%f",&rho);*/

printf("Enter the Factor of Safty For The Material Selected : ");

scanf("%f",&FS);

printf("Enter the Coefficient of Fluctuation of Speed : ");

scanf("%f",&Cs);

printf("Enter the Fluctuation of Energy : ");

scanf("%f",&DE);

if((fp=fopen("sd1.dat","r"))==NULL)

{

printf("Unable to Openn");

printf("Sorry!!! Please Try Again");

getch();

exit(0);

}

else

{

printf("File Opened Successfully!");

printf("nMatl. tsyttrho");

for(i=0;i<=max_matls;i++)

{

fscanf(fp,"%s %d %f",&matl[i],&syt[i],&Rho[i]);

printf("n %s t%dt%f",matl[i],syt[i],Rho[i]);

}

for(i=0;i<=0;i++)

{

printf("nEnter Material No,%d : ", i+1);

scanf("%s",&matl_in[i]);

for(j=0;j<=max_matls-1;j++)

{

if((strcmp(matl_in[i],matl[j]))==0)

{

Syt=syt[j];

Sd=Syt*1000000/FS;

D=(Sd*3600)/(Rho[j]*PI*PI*N*N);

Rad=(2*PI*N)/60;](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-77-2048.jpg)

![m=(4*DE)/(D*D*Rad*Rad*Cs);

k=m/(2*PI*D*Rho[j]*4);

t=sqrt(k);

b=4*t;

break;

}

else

{

/*printf("nMaterial is not Present In The List");

break;*/

continue;

}

}

}

}

clrscr();

printf("You have Selected the Material as %s",matl[0]);

printf("nFor the Entered Data : nDiameter Of The Flywheel is : %f m",D);

printf("nMass of The Flywheel is : %f kg",m);

printf("nThickness of The Flywheel is : %f m",t);

printf("nWidth of The Flywheel is : %f m",b);

getch();

}](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-78-2048.jpg)

![M) Calculate the module m by equating tangential load FT & bending strength FB

FT = FB

N) Select the next standard module (m) available.

O) Calculate the actual value of Dp with the new module from step N

Dp = 2d + 25 for keyed pinion

Dp = d + 25 for internal pinion

Use the above equation if the shaft diameter is given otherwise

Dp = m * Tp & select Dp such that it should

have higher value.

P) Calculate the actual value of

I. Pitch line velocity (Vp)

II. Velocity fact (Cv)

III. Tangential tooth load (Ft )

IV. Bending strength (FB)

Q) Select the material for the gear & calculate the value of (S0 * γ ) for both pinion

& gear.

R) Take the smaller value of (S0 * γ ) for calculating the face width (b).

S) Calculate face width (b) from the modified Lewis equation.

T) Calculate the face width (minimum) from standard proportion as

b = 8.5 * m

select the bigger value of face width from step S & T

2) DESIGN CHECK FOR DYNAMIC LOAD & LIMITING WEAR STRENGTH.

A) Calculate the dynamic load (Fd)

a) Find out the permissible error in profile as per the pitch line velocity.

b) Decide the class of manufacturing process as the permissible error found

in step a.

c) Find out the probable error in the teeth profile as per module.

d) Calculate the deformation factor “C”. This depends upon the material

of the gear &

pinion along with the type of teeth profile.

Deformation factor

C = a / (1 / Ep + 1 / Eg )

Here,

a is constant ratio as per teeth profile as,

a = 0.107 for 14.50

full depth.

a = 0.107 for 20.00

full depth.

a = 0.107 for 20.00

stub.

Ep = Young’s modulus of Pinion

Eg = Young’s modulus of Gear.

e) Calculate the dynamic load (Fd) as

Fd = Ft + {[21* Vp * (C * e * b + Ft)] / [21 * Vp + ( C * e * b + Ft )½

]}

Here,

Ft = tangential tooth load

Vp = pitch line velocity

C =deformation factor

E = probable error in tooth cutting

B = face width

Fd = dynamic load

B) Calculate the limiting wear strength Fw :-

a) Calculate size factor

Q = 2 * Tp * Tg / (Tp + Tg ) for external gear](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-80-2048.jpg)

![#include<stdio.h>

#include<conio.h>

#define PI 3.141592654

#define max_matls 5

#define max_input 4

void main()

{

float T,fs,fcb,fsf,fsf1,fsf2,d,D,L,l,w,t,fsk,fck,fsk1,fck1,tf;

float D1,d1,D2,i1,fsb,tp;

int n,j,i;

char matl[max_matls][25],matl_in[max_matls][25],Mtl;

float SS[max_matls]={0},CS[max_matls]={0};

FILE *fp;

clrscr();

fflush(stdin);

clrscr();

printf("nEnter value of torque (Newton-mm) ");

scanf("%f",&T);

/*printf("nEnter value of shear stress for shaft (Newton-mm2) ");

scanf("%f",&fs);

printf("nEnter value of shear stress for flange material (Newton-mm2) ");

scanf("%f",&fsf);*/

if((fp=fopen("CPdata.dat","r"))==NULL)

{

printf("Unable to Openn");

printf("Sorry!!! Please Try Again");

getch();

exit(0);

}

else

{

printf("nFile Opened Successfully!");

printf("nMaterialtShear StresstCrushing Stress");

for(i=0;i<=max_matls-1;i++)

{

fscanf(fp,"%s%f%f",&matl[i],&SS[i],&CS[i]);

printf("n%stt%ft%f",matl[i],SS[i],CS[i]);

}

for(i=0;i<=3;i++)

{

if(i==0)

printf("nEnter Material for Shaft : ");

else

{

if(i==1)

printf("nEnter Material for Flange Coupling](https://image.slidesharecdn.com/camdpractical-150318103014-conversion-gate01/75/Computer-Aided-Manufacturing-Design-86-2048.jpg)