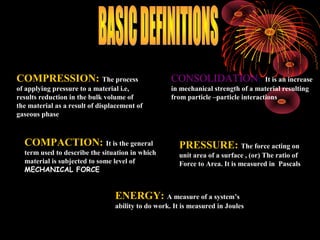

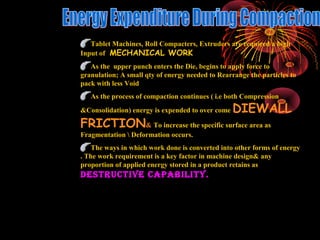

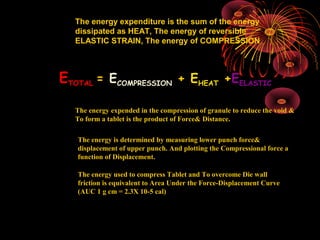

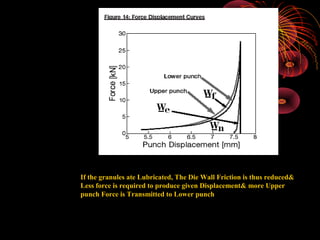

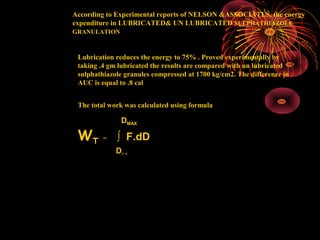

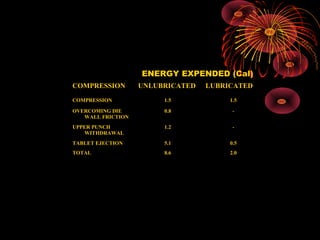

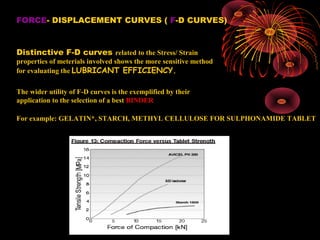

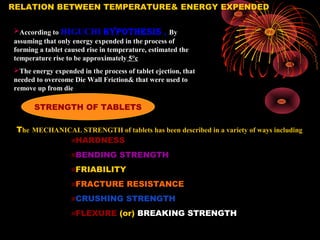

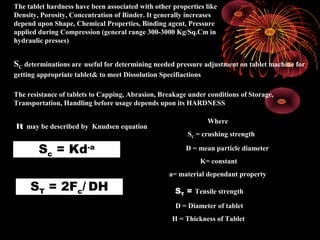

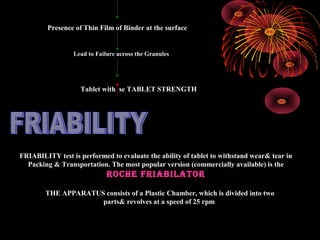

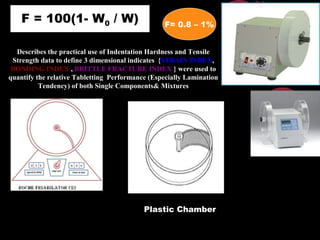

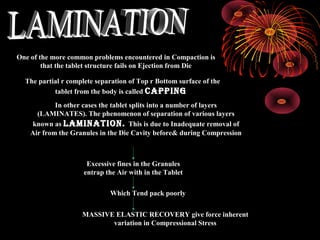

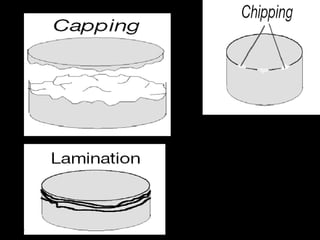

The document discusses various topics related to tablet compression including compression, consolidation, compaction, energy involved, tablet strength parameters like crushing strength and friability, and issues like lamination. It provides details on the energy expended during different stages of compression and how lubricants can reduce this. Tablet strength is found to increase with compression force and binder concentration but decrease with porosity. Tests for evaluating tablet properties like hardness, friability and lamination tendency are also summarized.