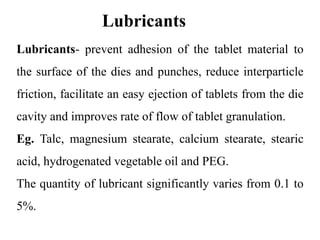

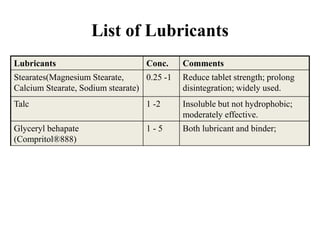

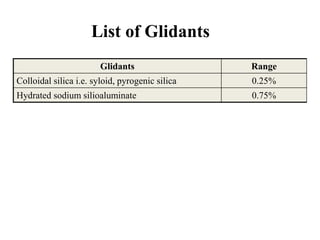

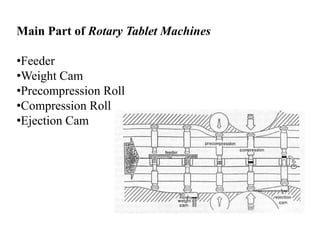

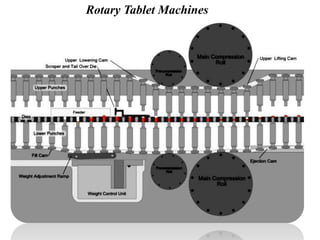

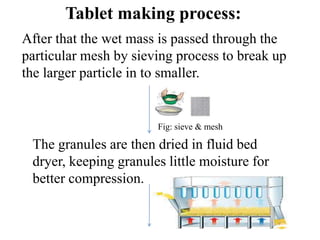

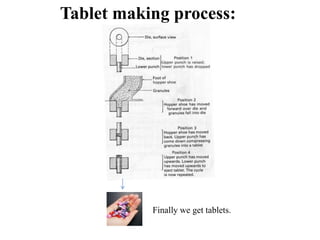

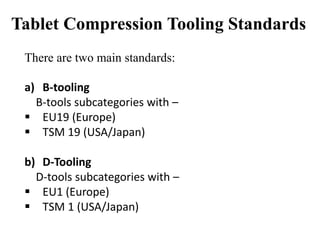

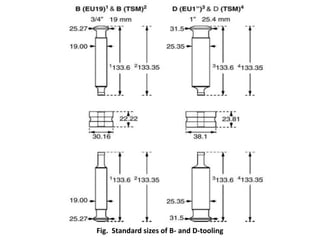

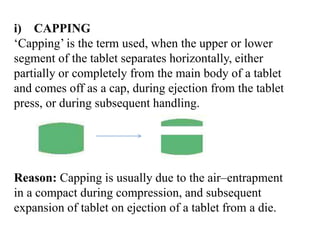

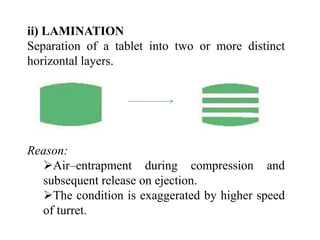

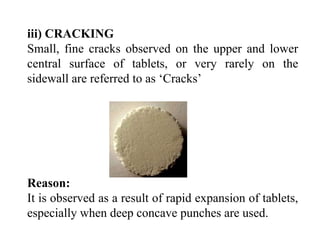

The document discusses tableting technology, focusing on the role of lubricants and glidants in preventing adhesion and improving flow during tablet manufacturing. It details the tablet-making process, the machinery involved, and various tooling standards, while also highlighting common defects such as capping, lamination, and cracking. Each defect's causes are explained, emphasizing the importance of managing air entrapment and compression conditions.