This document discusses comminution mechanisms, which are the ways that particles fracture during size reduction processes. It describes four main mechanisms: shatter (impact fracture), cleavage, attrition, and abrasion. Shatter occurs via high-speed impacts and produces a broad size distribution. Cleavage happens under lower compression and yields a narrower size range. Attrition is particle wear during interactions like grinding. The document explains the factors that influence fracture, such as flaws and applied stress. It also reviews theories of how energy relates to breakage. The goal is to understand particle fracture to improve efficiency of comminution equipment and processes.

![Introduction

• Why comminution?

………..

To create particles in a certain size and

shape

…….…

To increase the surface area available for

next process

………..

To liberate valuable minerals held within

particles[2]

3](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-3-2048.jpg)

![Introduction

• Grinding and crushing usually account for more than 30

to 50% of the total power used in the concentration

process, but this can rise as high as 70% for hard finely

dispersed and intergrown ores.[1] but about 5 % of all

electricity generated is used in size reduction[2]

4](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-4-2048.jpg)

![Introduction

• Where this 'lost' energy is consumed ?

1. Deforming the particle to its elastic limit

2. Compacting particles after fracture

3. Overcoming friction between particles

4. Elastically deforming milling surfaces

5. Deformation of fractured particles

This energy is dissipated as heat.[4]

5](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-5-2048.jpg)

![Introduction

• Aim:

• The general goal of the project Mechanisms of

comminution is to enhance understanding of particle

breakage, which shall lead to improved comminution

systems and more efficient utilization of energy for size

reduction and mineral liberation.[3]

6](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-6-2048.jpg)

![Comminution Theory

• In the crystalline lattice of minerals, these inter-atomic bonds are

effective only over small distances, and can be broken if extended by

a tensile stress. [5]

7](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-7-2048.jpg)

![Comminution Theory

• The relationship between energy and breakage may be

expressed in the equation:

dE= -K.dx/dxn

• Rittinger: the new surface area produced proportional

to the energy consumed [6]

n=1 E=K(1/x2 – 1/x1)

8](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-8-2048.jpg)

![Comminution Theory

Kick: the same relative reduction in volume is obtained

for constant energy input per unit mass irrespective of the

original size.

n=2 E=K.ln(x1/x2)

Kick's law is reasonably accurate in the crushing range

above about 1 cm in diameter [6]

9](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-9-2048.jpg)

![Comminution Theory

• Bond: the work input is proportional to the new crack

tip length produced in particle breakage.

n=1.5 E= 2K(1/√x2 -√x1)

• Avilable in the range of conventional rod-mill and ball-

mill grinding.[6]

10](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-10-2048.jpg)

![Comminution Theory

[8]

11](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-11-2048.jpg)

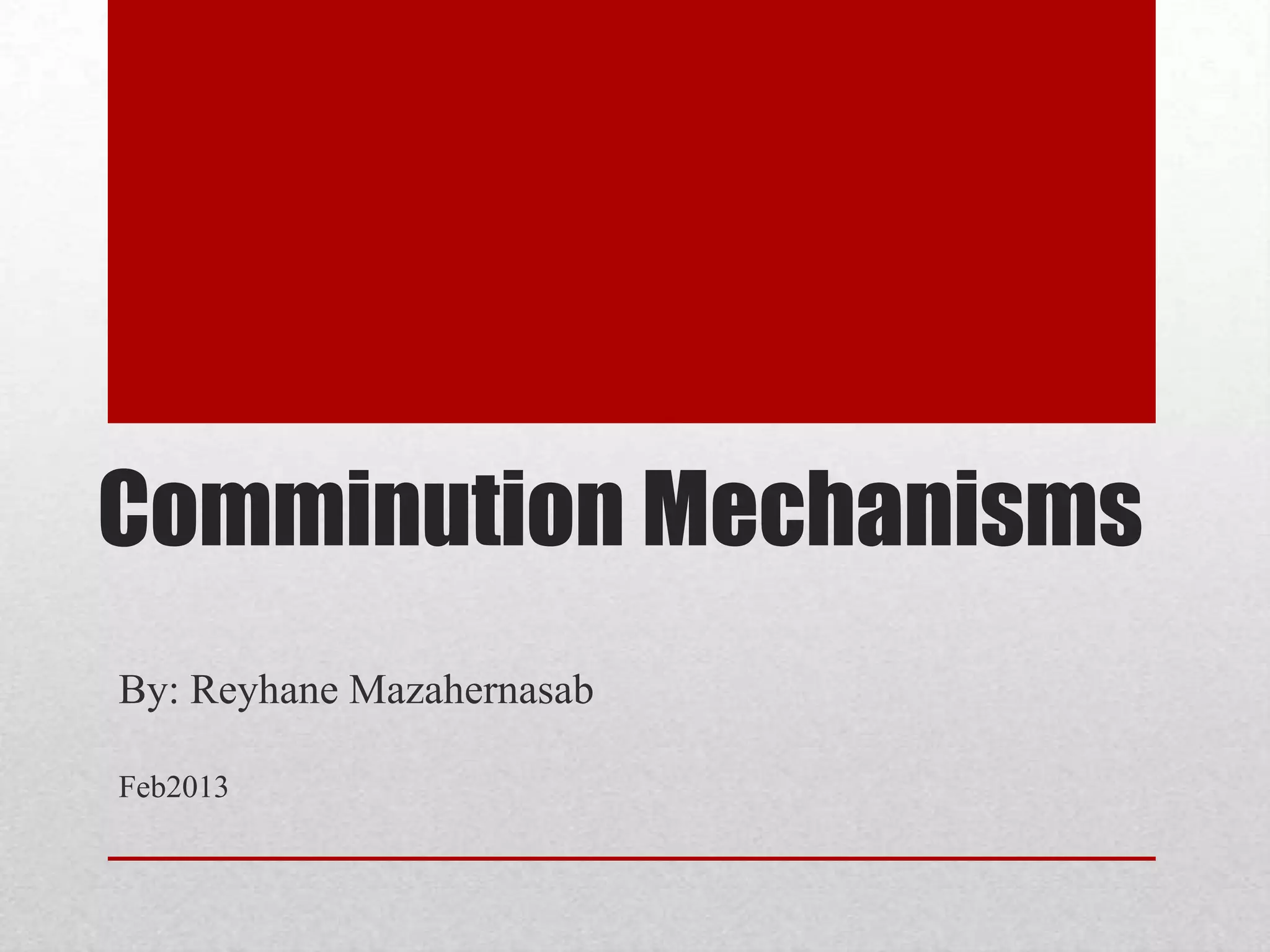

![Mechanics of particle fracture

Flaws are stress concentrators [9]

• Even when rocks are uniformly loaded, the internal stresses are not

evenly distributed[5]

12](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-12-2048.jpg)

![Mechanics of particle fracture

• Griffith showed that materials fail by crack propagation

when this is energetically feasible.[5]

• For crack to propagate:

Strain energy > surface energy created

Requires appropriate crack propagation mechanism[2]

13](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-13-2048.jpg)

![Mechanics of particle fracture

Virtually no stress is

required to bring about

bond breakage, stress is

required to provide the

energy necessary for

crack propagation and

the consequent

production of new

surface. [7]

15](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-15-2048.jpg)

![Mechanics of particle fracture

• It should be noted that although it is not necessary to

provide enough energy to strain all bonds to the point of

breaking, more energy is required than that which is just

sufficient to provide the free energy of the new surfaces.

Because bonds away from the eventual fracture surfaces

also become strained, hence absorb energy.[7]

16](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-16-2048.jpg)

![Mechanics of particle fracture

• Rumbf:

for smaller particles having fewer flaws, the applied

stress at which fracture occurs is greater.

Irrespective of the distribution and density of flaws, a

greater stress is required to fracture a smaller particle:

strain energy is proportional to volume so the amount of

energy available at a given stress condition decreases as

the particle size decreases.[7]

17](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-17-2048.jpg)

![Mechanics of particle fracture• The manner in which a particle fractures depends on (i)

the nature of the particle; and (ii) the manner in which the

fracture force is applied.[13]

• Grain boundary fracture: The fracture toughness for

grain boundary cracking is lower than that for random

plane intragranular cracking, because atoms are arranged

irregularly in the grain boundary region.

[12]

18

AB, showing regions of coincidence and non-coincidence

between atoms in the neighbouring grains](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-18-2048.jpg)

![Mechanics of particle fracture

19

• Interfacial fracture: Cracking along these interfaces will

occur preferentially whenever they are present. Like

sedimentary rocks and conglomerates.

• Interphase fracture: interphase fracture is defined as

cracking along the boundary between two different

crystalline phases. [12]

Bonding across the boundary between the different

phases is stronger than that for interfacial boundaries

but not as strong as that across grain boundaries in the

pure, single-phase mineral. [12]](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-19-2048.jpg)

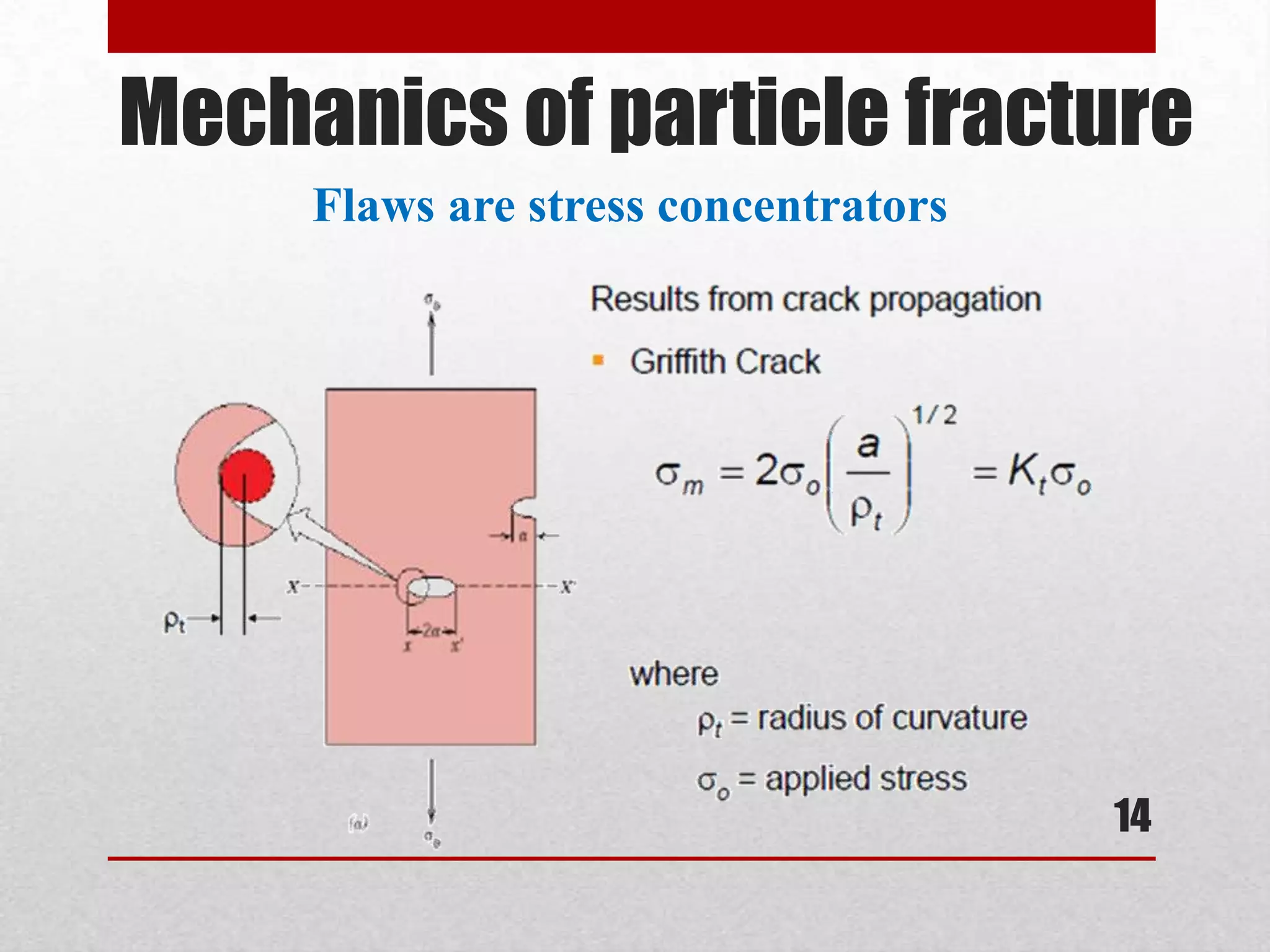

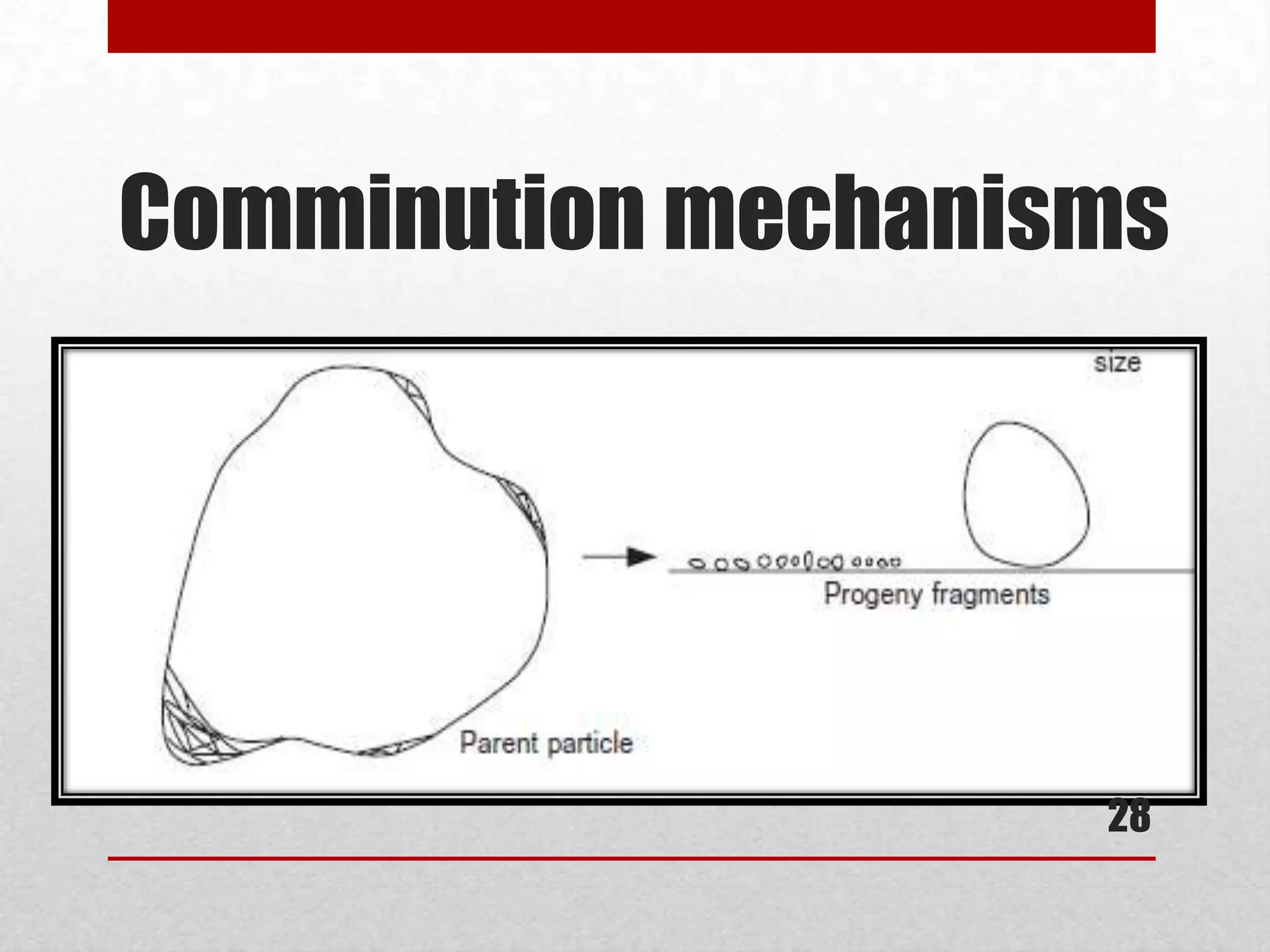

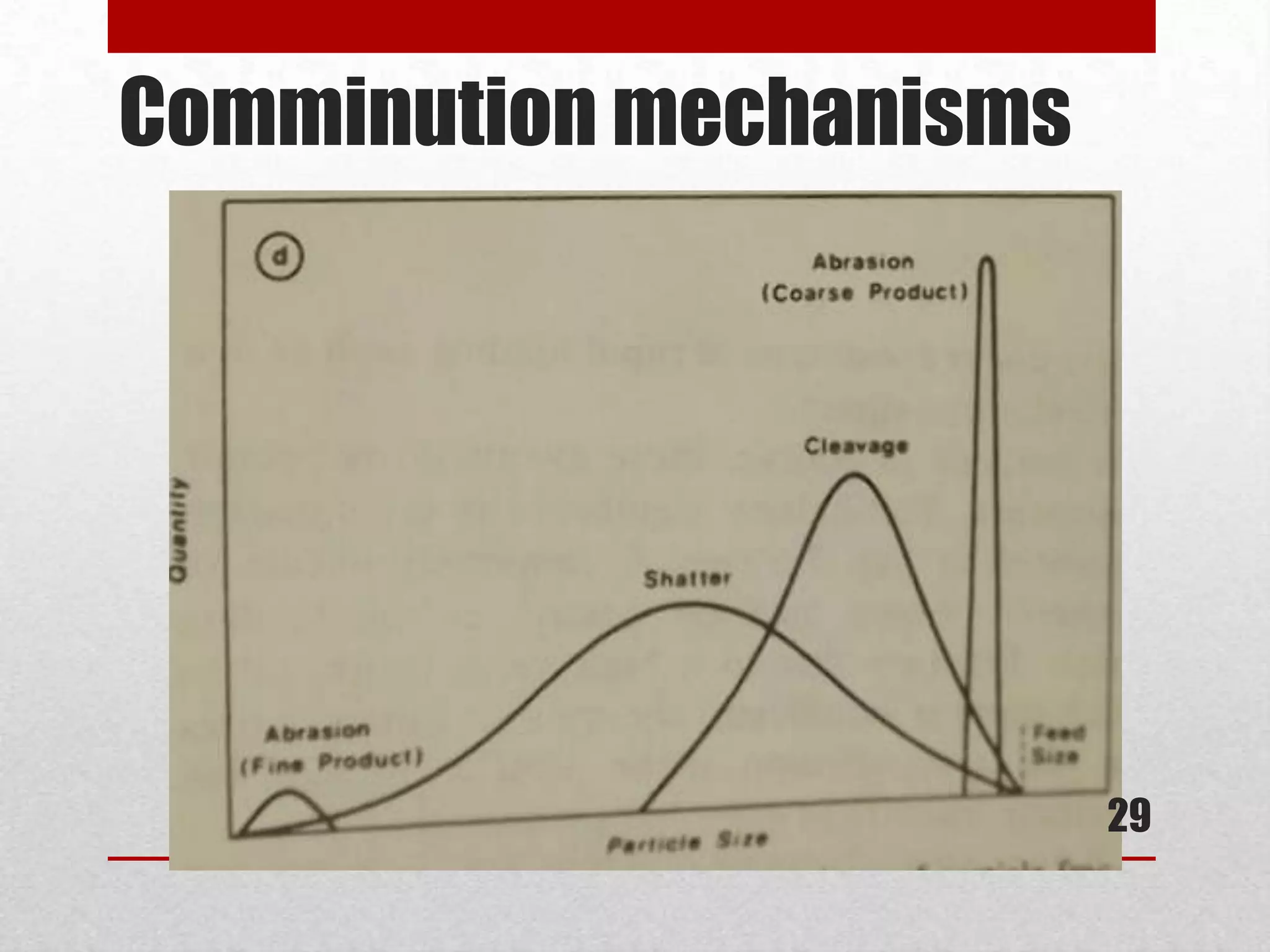

![Comminution mechanisms

• Shatter (impact):

• This mechanism of fracture is induced by rapid

application of compressive stress.

• high speed 10 – 2000 m.s-1 [10]

• A broad spectrum of product sizes is produced and this

process is unselective

20](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-20-2048.jpg)

![Comminution mechanisms

• shattering process consists of a series of steps in which the

parent particle is fractured and this is followed immediately

by the sequential fracturing of successive generations of

daughter fragments until all of the energy available for

fracture is dissipated.

• Examples: industrial autogenous, rod and ball mills. [11]

21](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-21-2048.jpg)

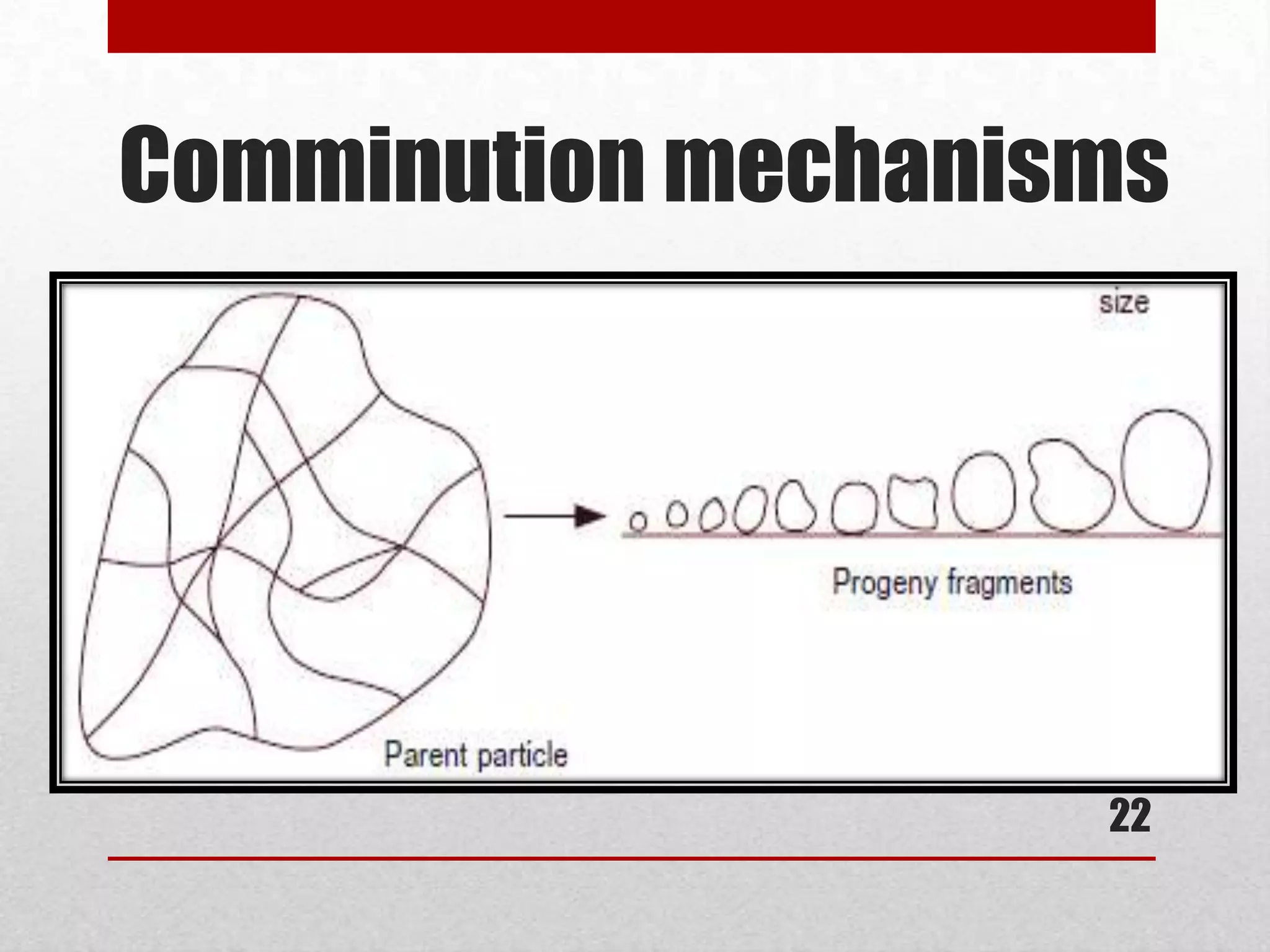

![Comminution mechanisms

• Cleavage: Strain is applied as compression stress

• Occurs when the energy applied is just sufficient to load

comparatively few regions of the particle to the fracture

point and only a few particles result. [7]

23](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-23-2048.jpg)

![Comminution mechanisms

• When the original solid has some preferred surfaces

along which fracture is likely to occur, cleavage results.

• The size distribution of the product particles is relatively

narrow [11]

• low speed 0,01 – 10 m.s-1

• Examples: jaw crushers, toggle crushers. [10]

24](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-24-2048.jpg)

![Comminution mechanisms

• Attrition: Strain between two or more solid

surfaces as a result of shearing action[10]

• Attrition occurs when the particle is large and the stresses

are not large enough to cause fracture.

26](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-26-2048.jpg)

![Comminution mechanisms

• parent particle hardly changes size but the attrition

process generates a significant number of particles that

are much smaller than the parent size.

• Examples: occurs in autogenous mills where large

particles are present to act as media.[11], shearing action

between ring sieve and rotor in rotor beater mills, cross

beater mills, ultra-centrifugal mills, etc. [10]

27](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-27-2048.jpg)

![References

• [1] Progress in mineral processing technology, Halim Demirel and Salih

Ersayin, Hacettepe university,Ankara, 1994

• [2] an E-book chapter 10

• [3] http://www.ltu.se/centres/camm

• [4] http://www.chemeng.ed.ac.uk

• [5] Mineral Processing Technology, Recovery, by Barry A. Wills, Tim

Napier-Munn., Elsevier Science & Technology Books, October 2006

• [6] mineral crushing and grinding circuits, A.J. Lynch, Julius Kruttshnitt

Mineral Research Centre, department of mining and metallurgical

Engineering,university of Queensland, Australia, 1989

• [7] introduction to mineral processing, Errol G. Kelly, David J Spottswood

1989

31](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-31-2048.jpg)

![References

• [8] http://tresen.vscht.cz/kot/english/files/2012-03-particle-sizing-

comminution

• [9] www.scs.illinois.edu/~chem584/.../chem584.mechanicalfailure

• [10] Size reduction within the context of sample preparation, Helmut Pitsch,

Retsch Application Support

• [11] Modeling and Simulation of Mineral Processing Systems, R.P. King

Department of Metallurgical Engineering University of Utah, USA, 2001

• [12] Fracture toughness and surface energies of minerals: theoretical

estimates for oxides, sulphides, silicates and halides D. Tromans , J.A.

Meech, September 2002

• [13] Chemical Metallurgy, Chiranjib Kumar Gupta, 2003

32](https://image.slidesharecdn.com/presentation1-130624080440-phpapp01/75/Comminution-mechanism-32-2048.jpg)