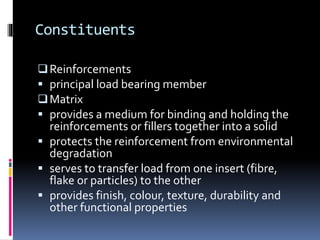

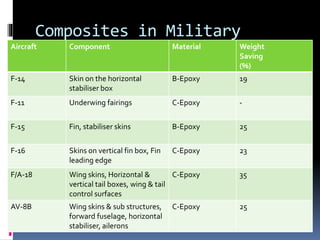

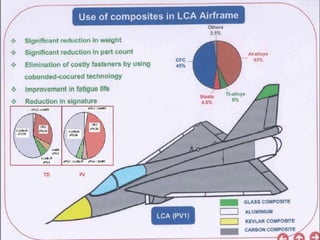

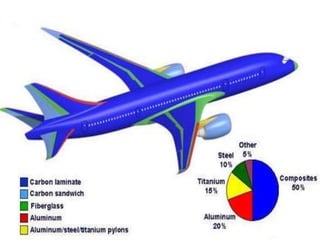

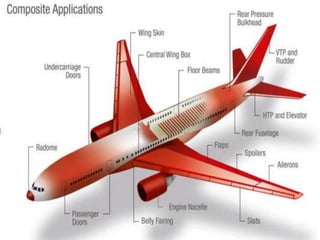

This document discusses the use of composite materials in aircraft structures. It defines composites as materials made from two or more constituent materials combined to produce improved properties. Composites provide benefits for aircraft like high strength to weight ratios, corrosion and impact resistance, and the ability to form complex shapes. Common composite constituents in aircraft are fiber reinforcements within polymer, metal, or ceramic matrices. Applications of composites in aircraft include fuselage and wing skins due to their weight savings over metal. While composites provide advantages, their production is more expensive and recycling presents challenges compared to conventional materials.