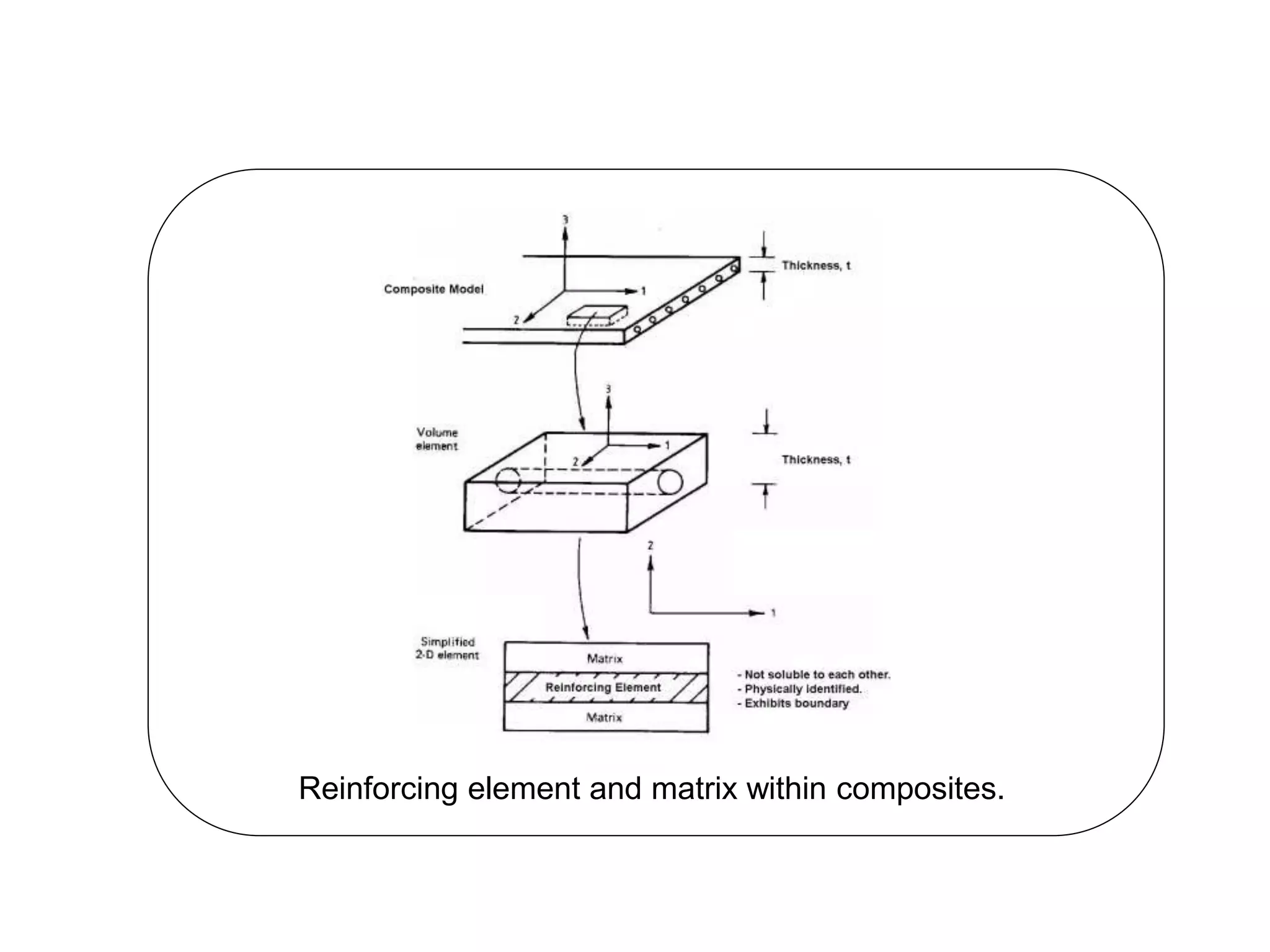

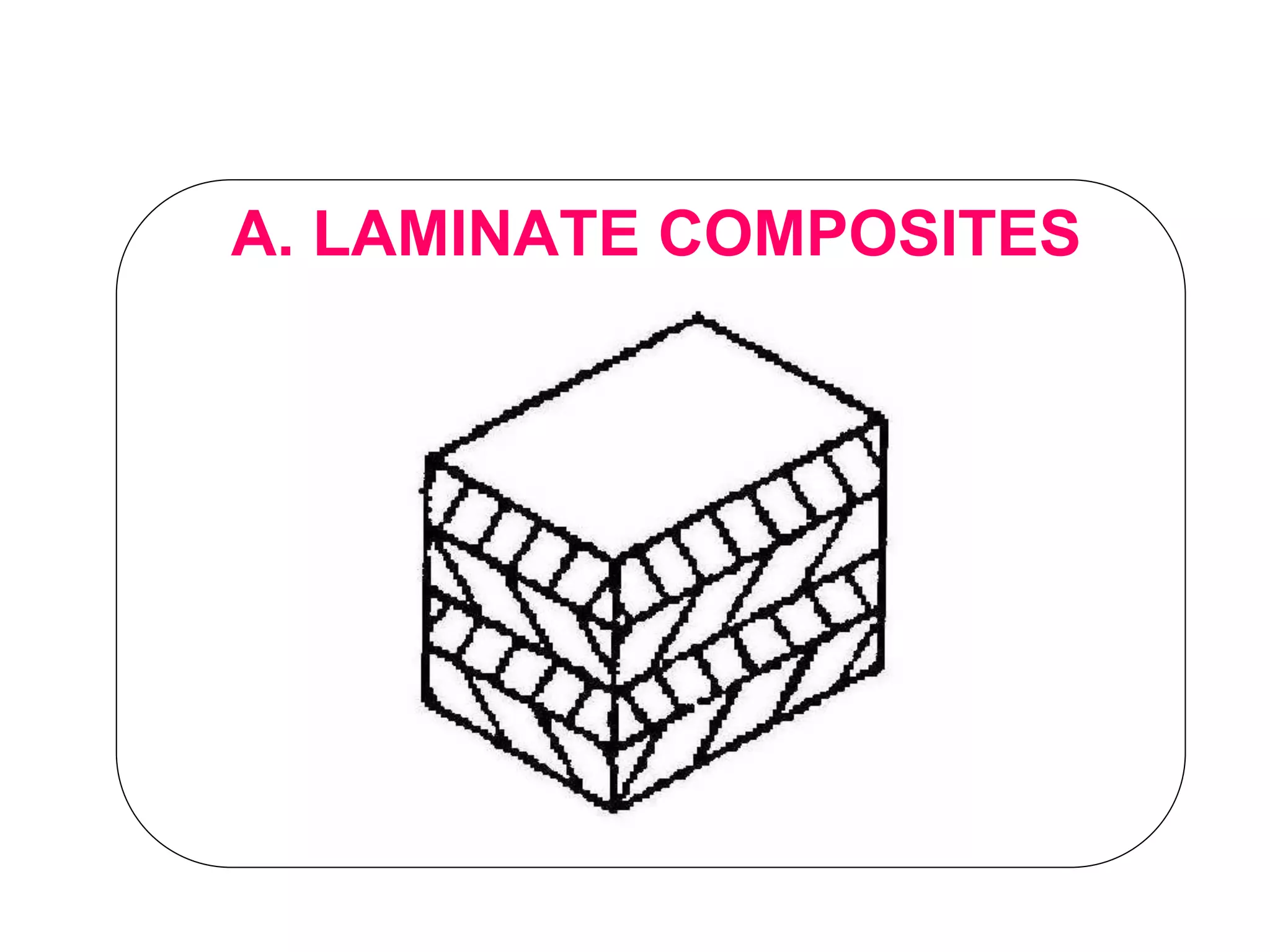

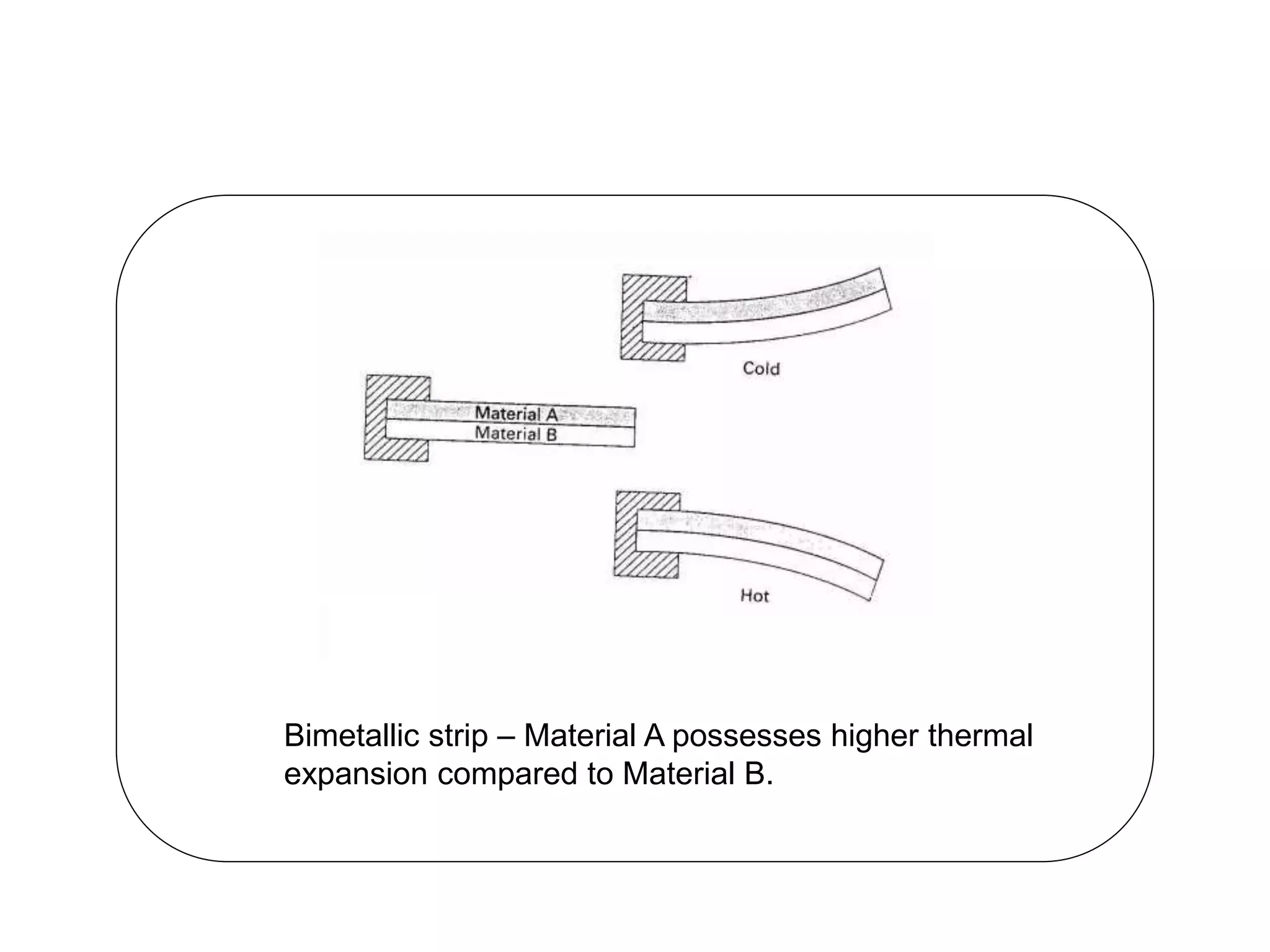

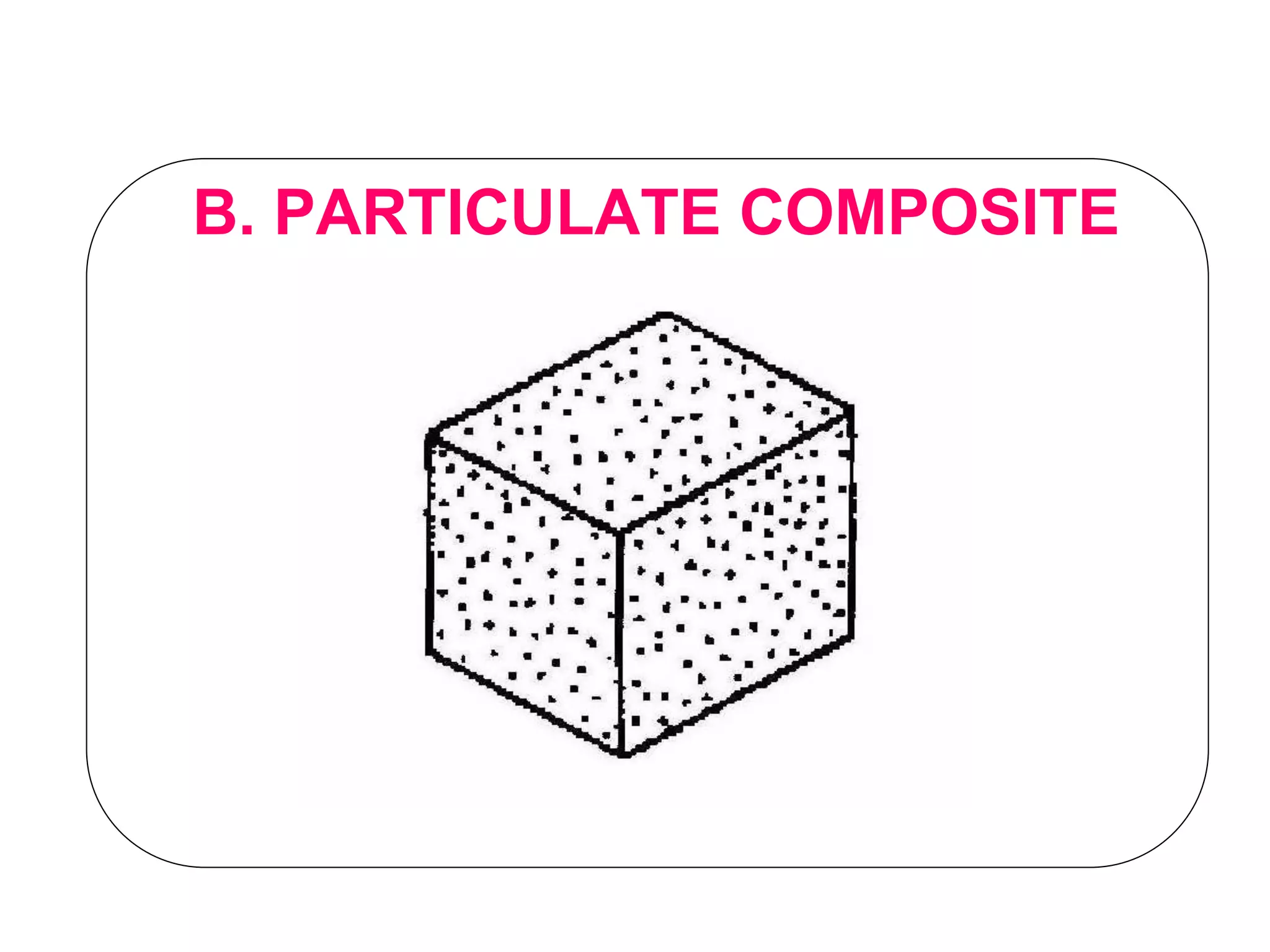

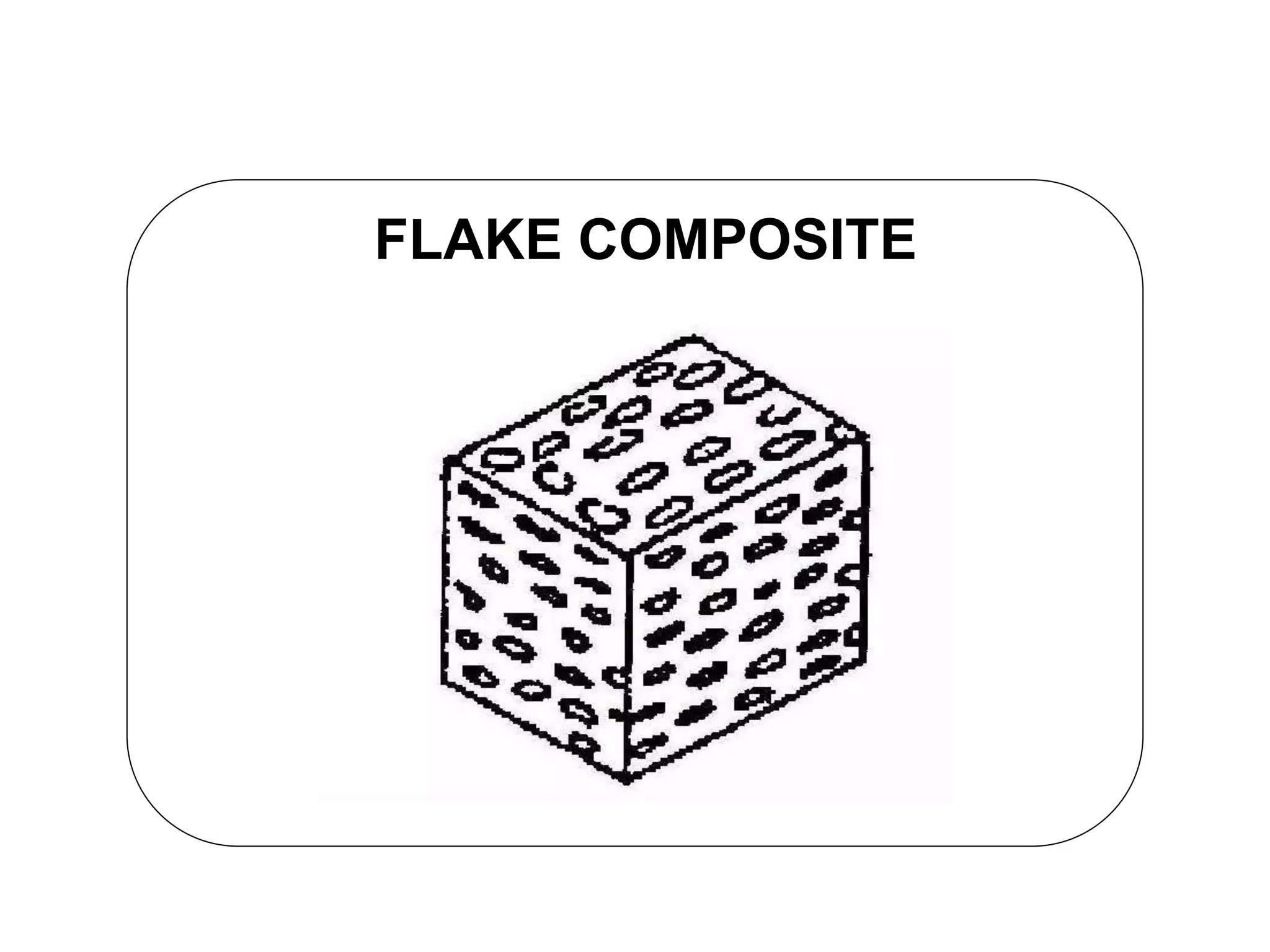

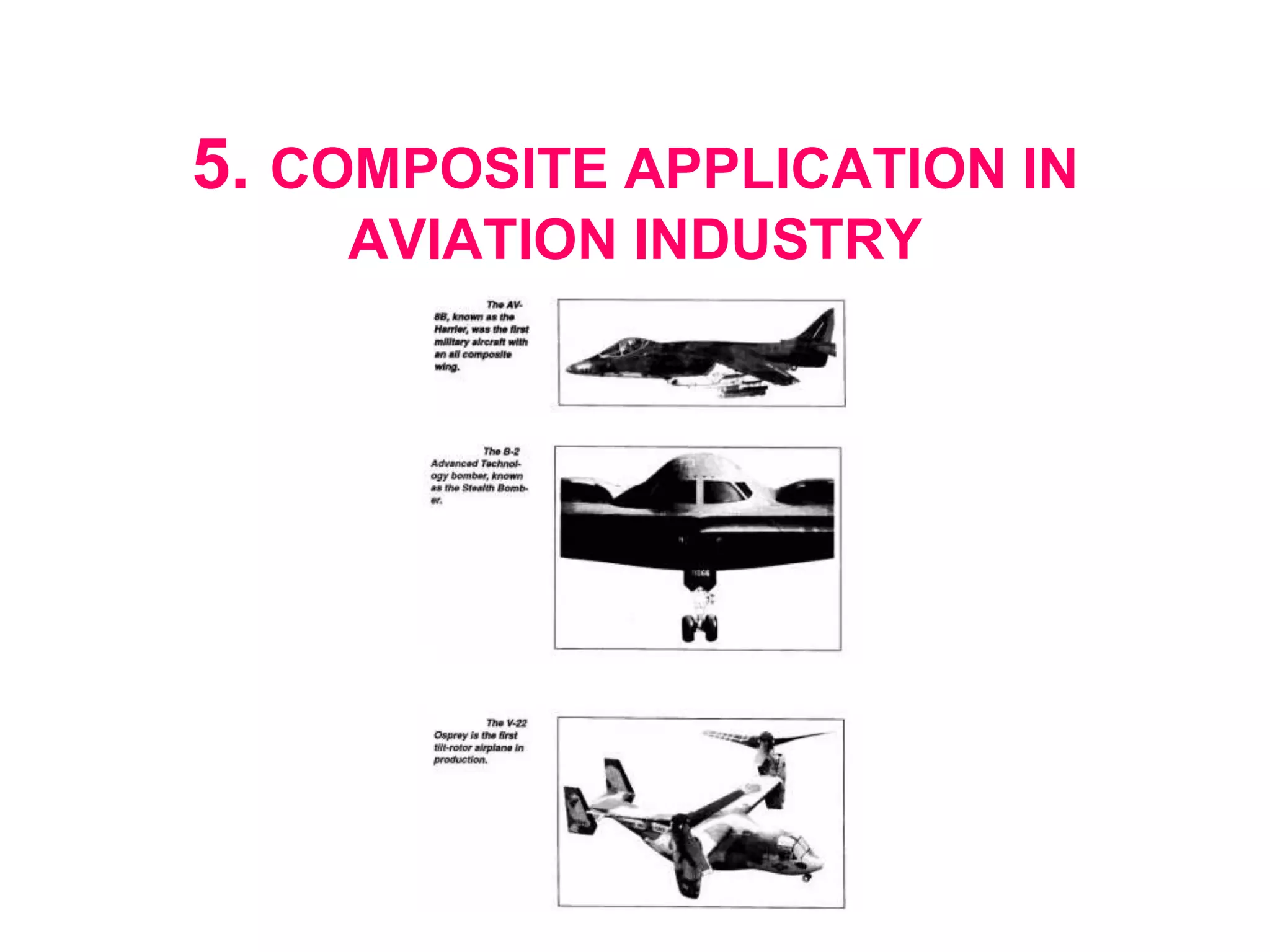

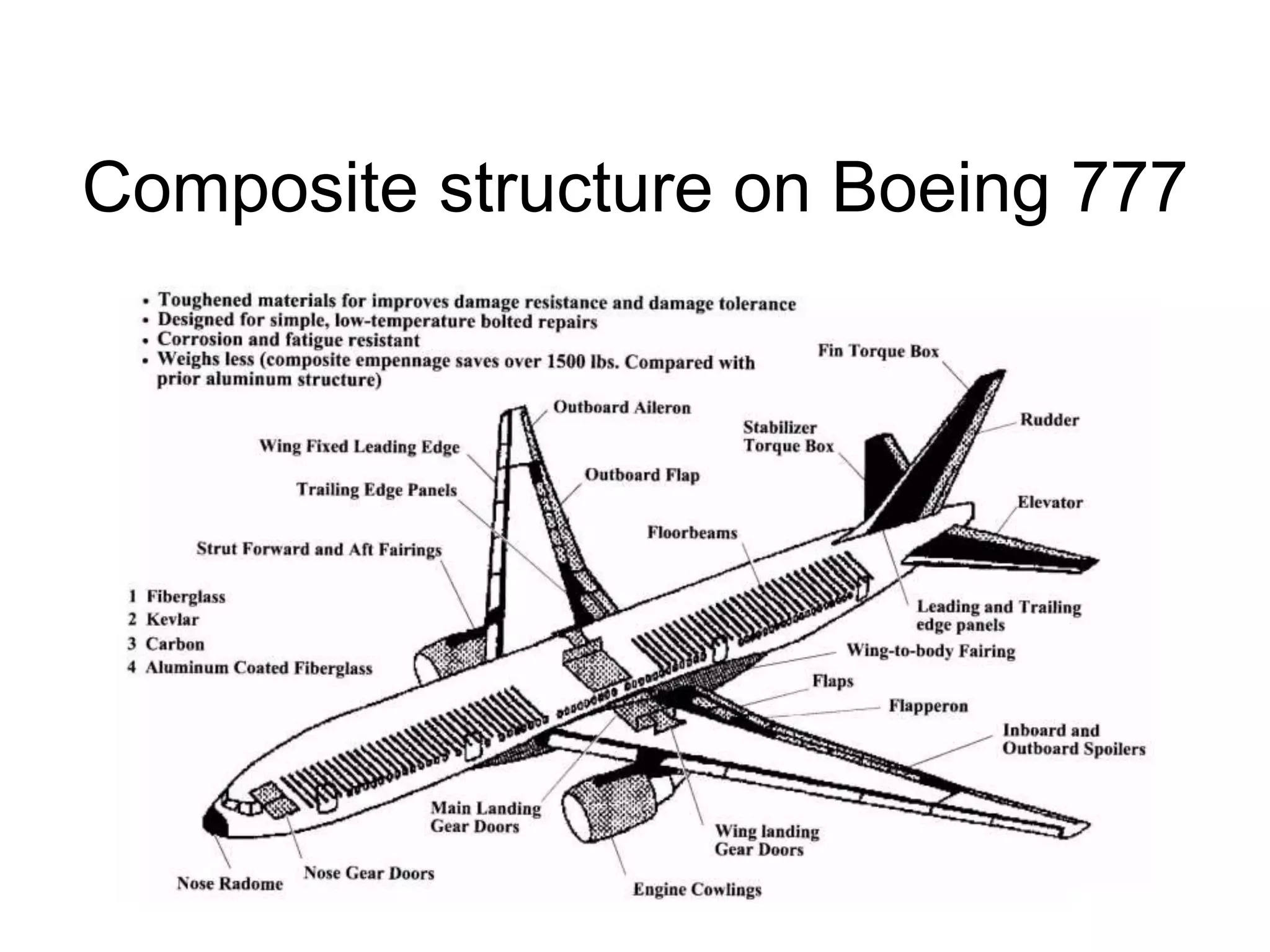

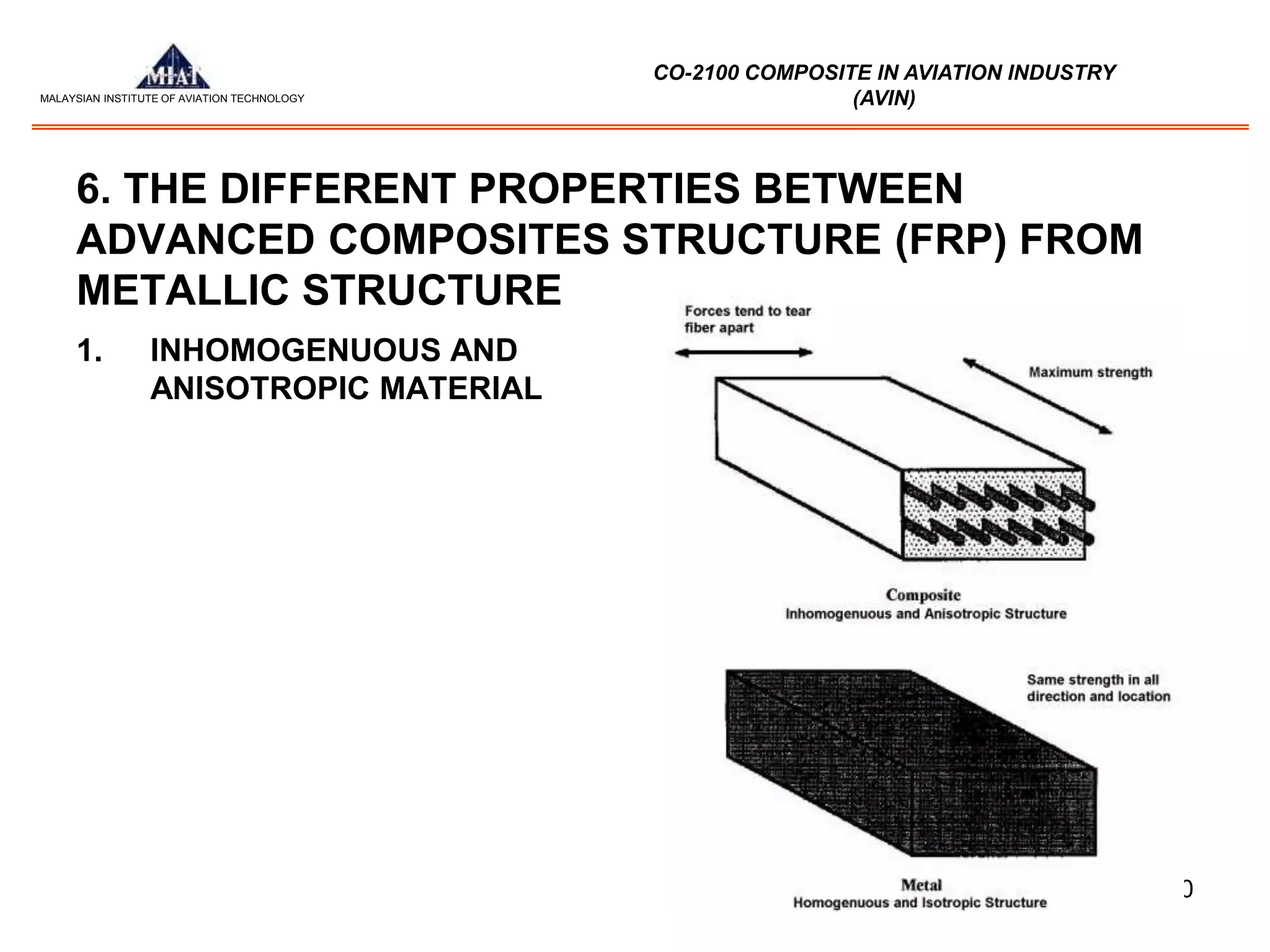

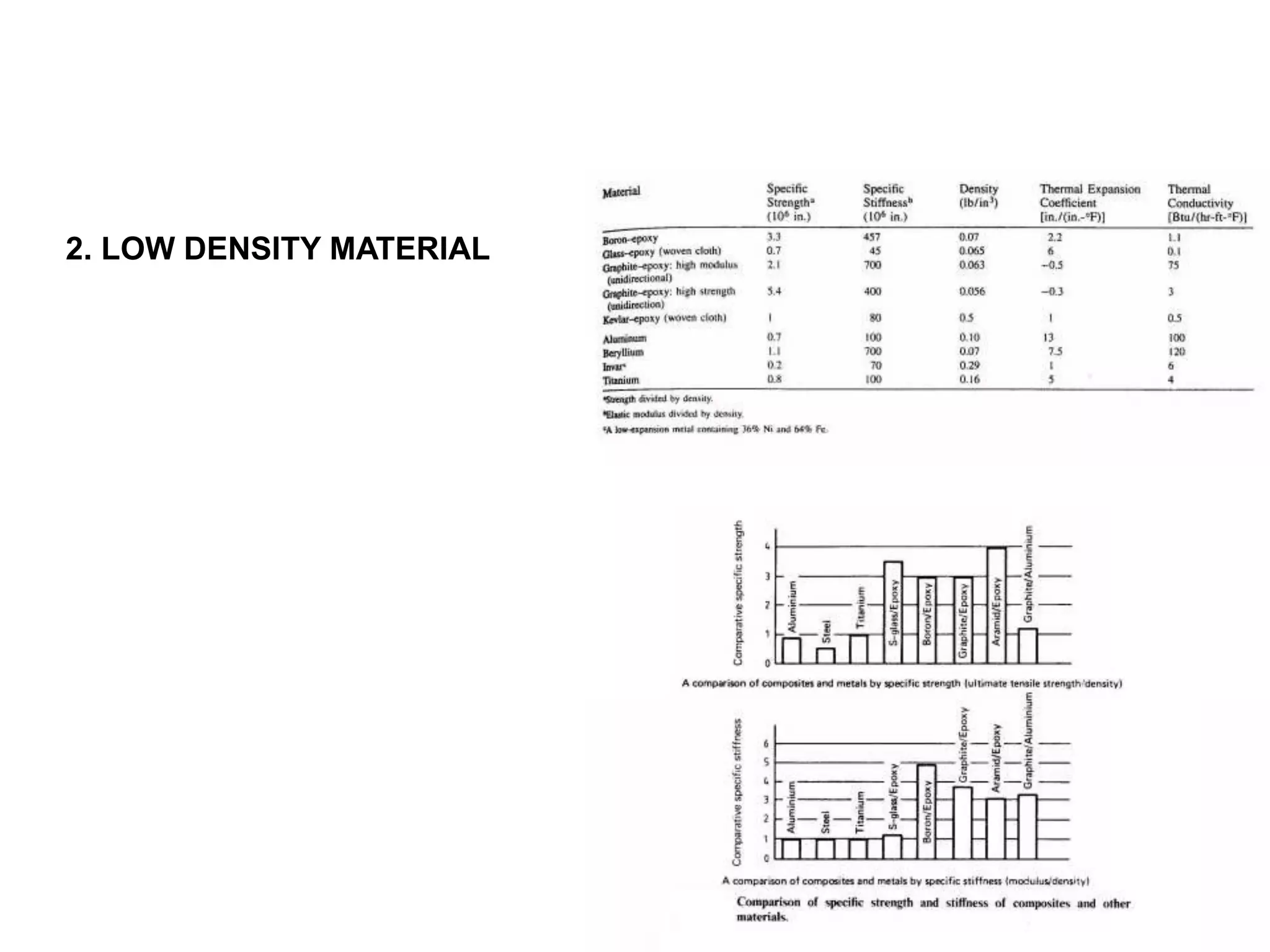

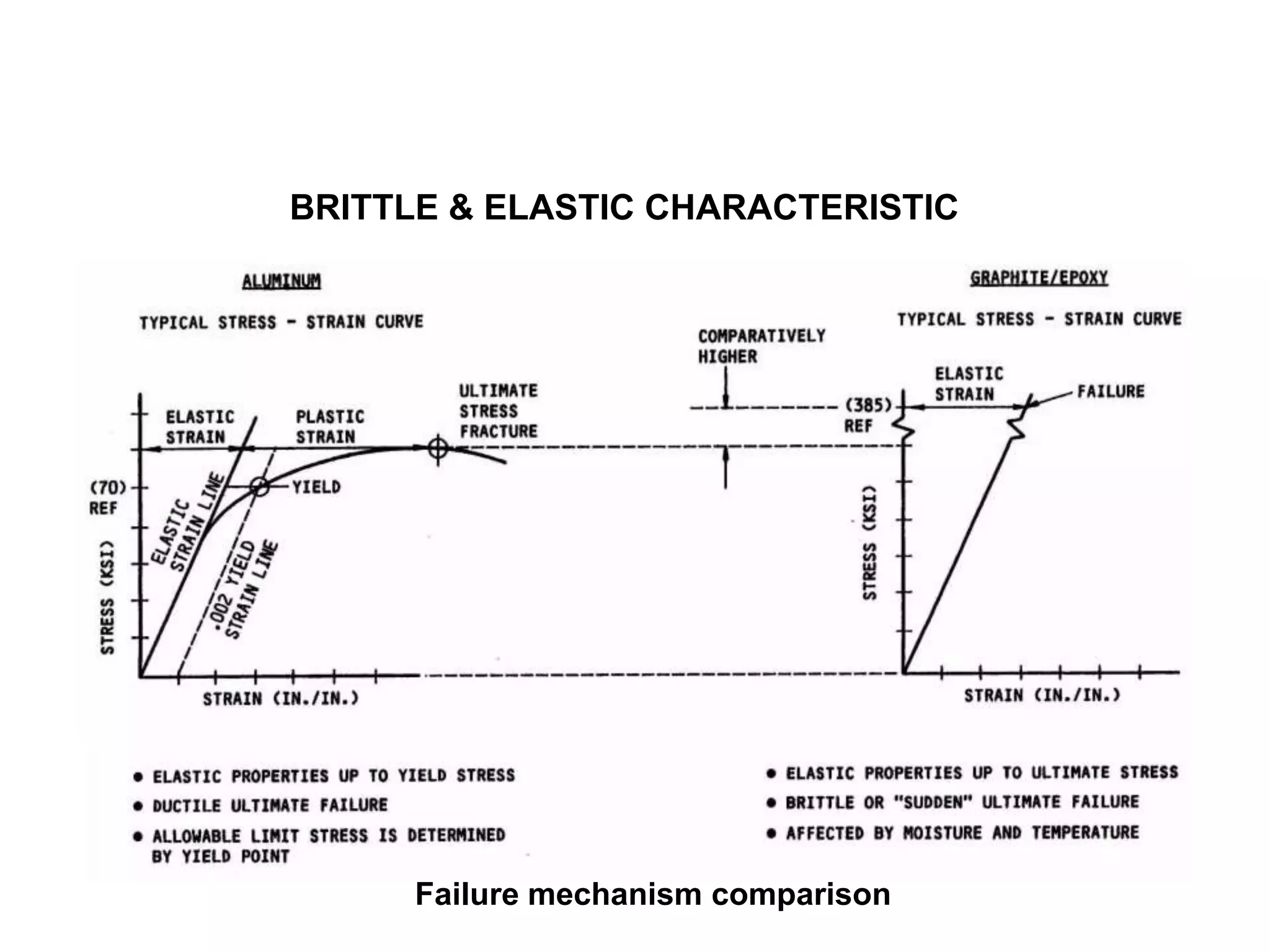

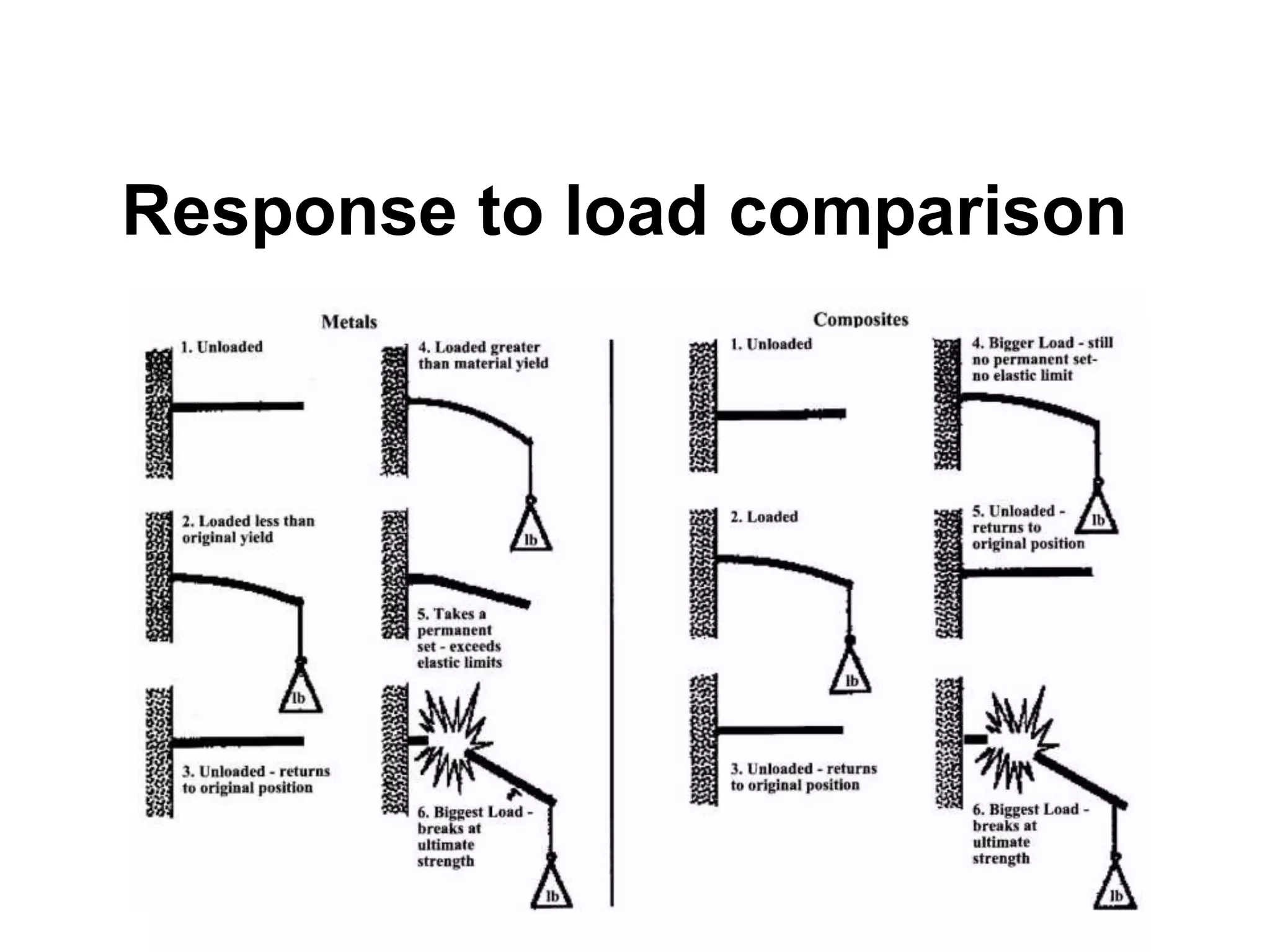

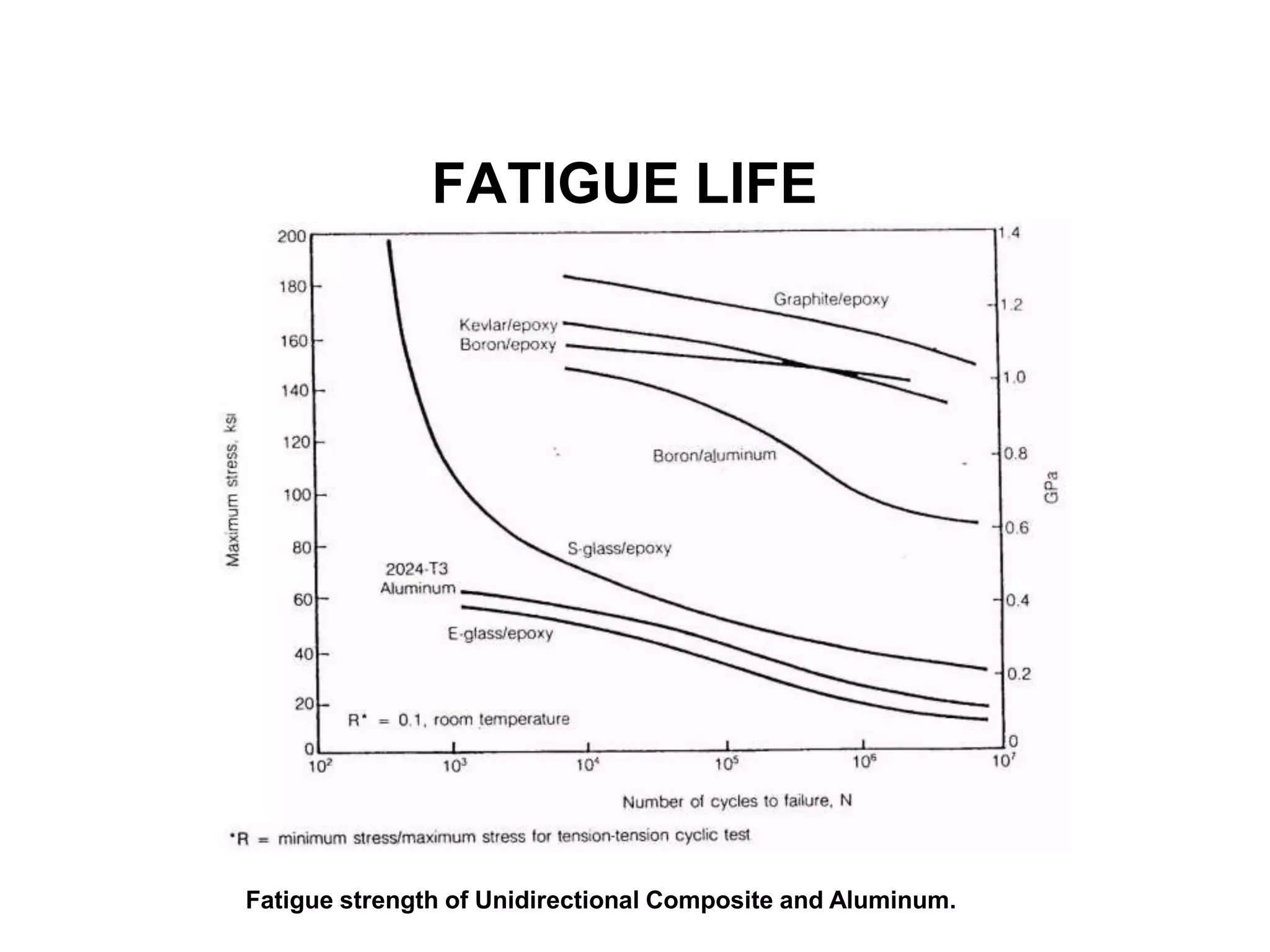

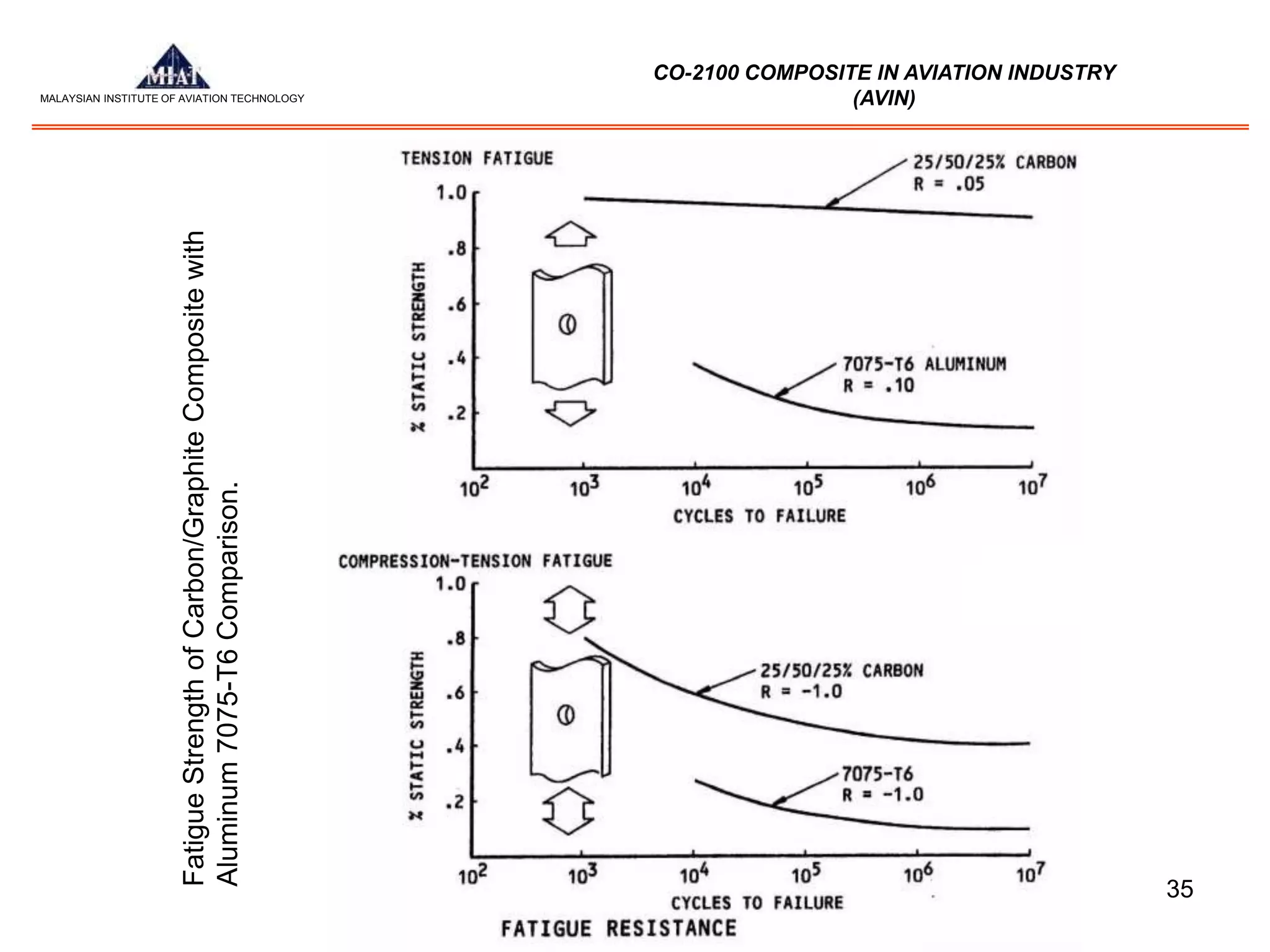

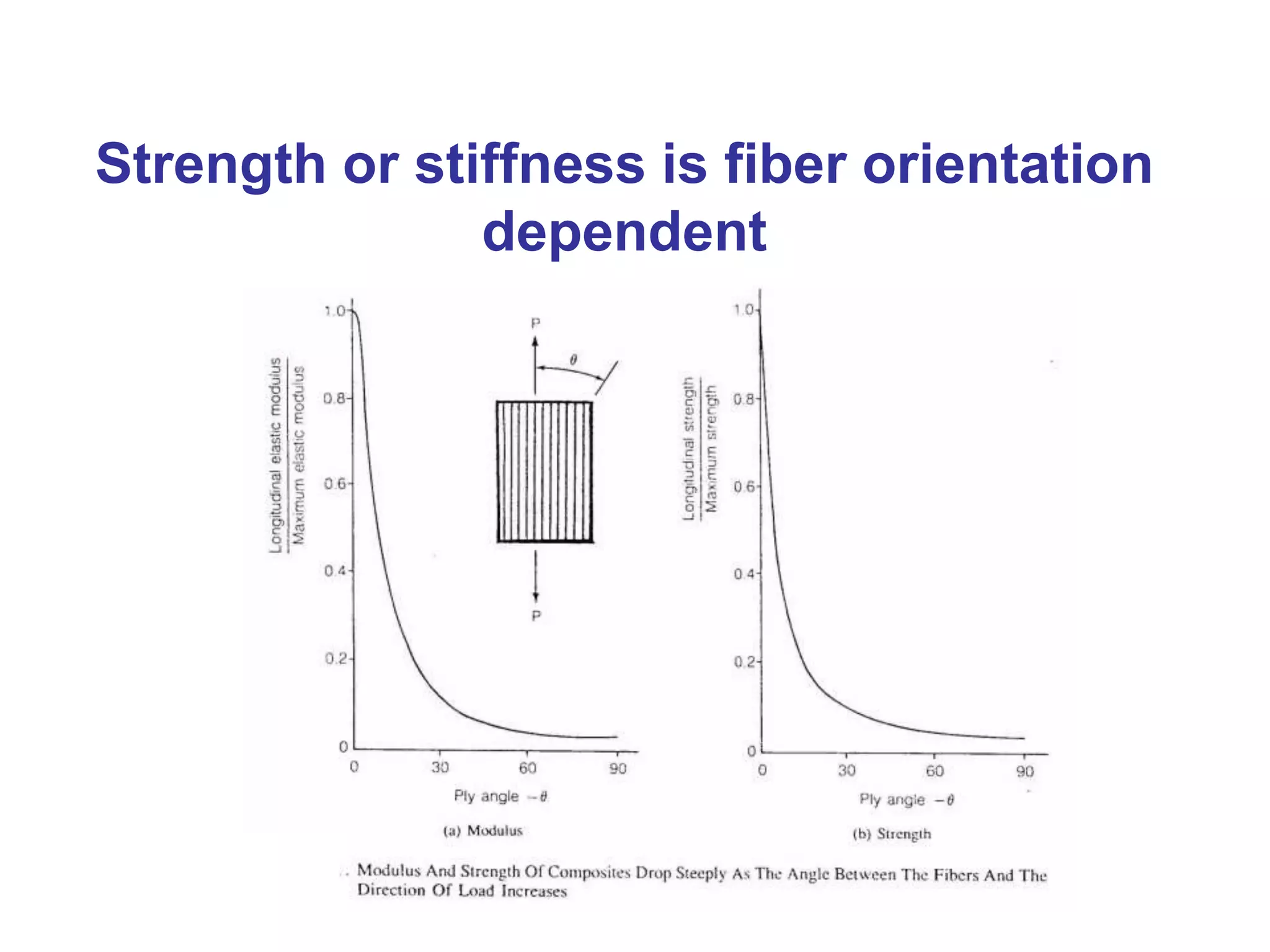

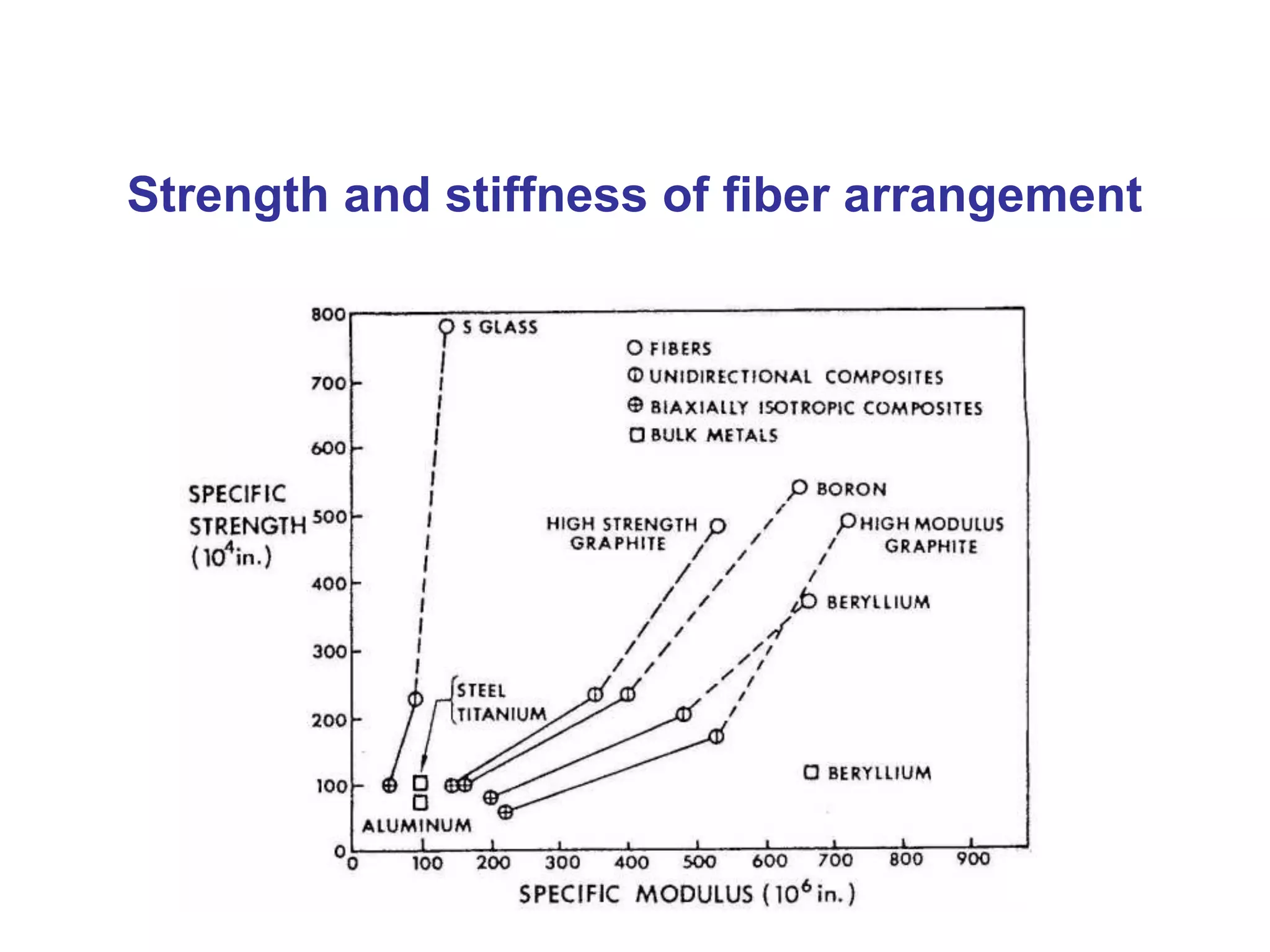

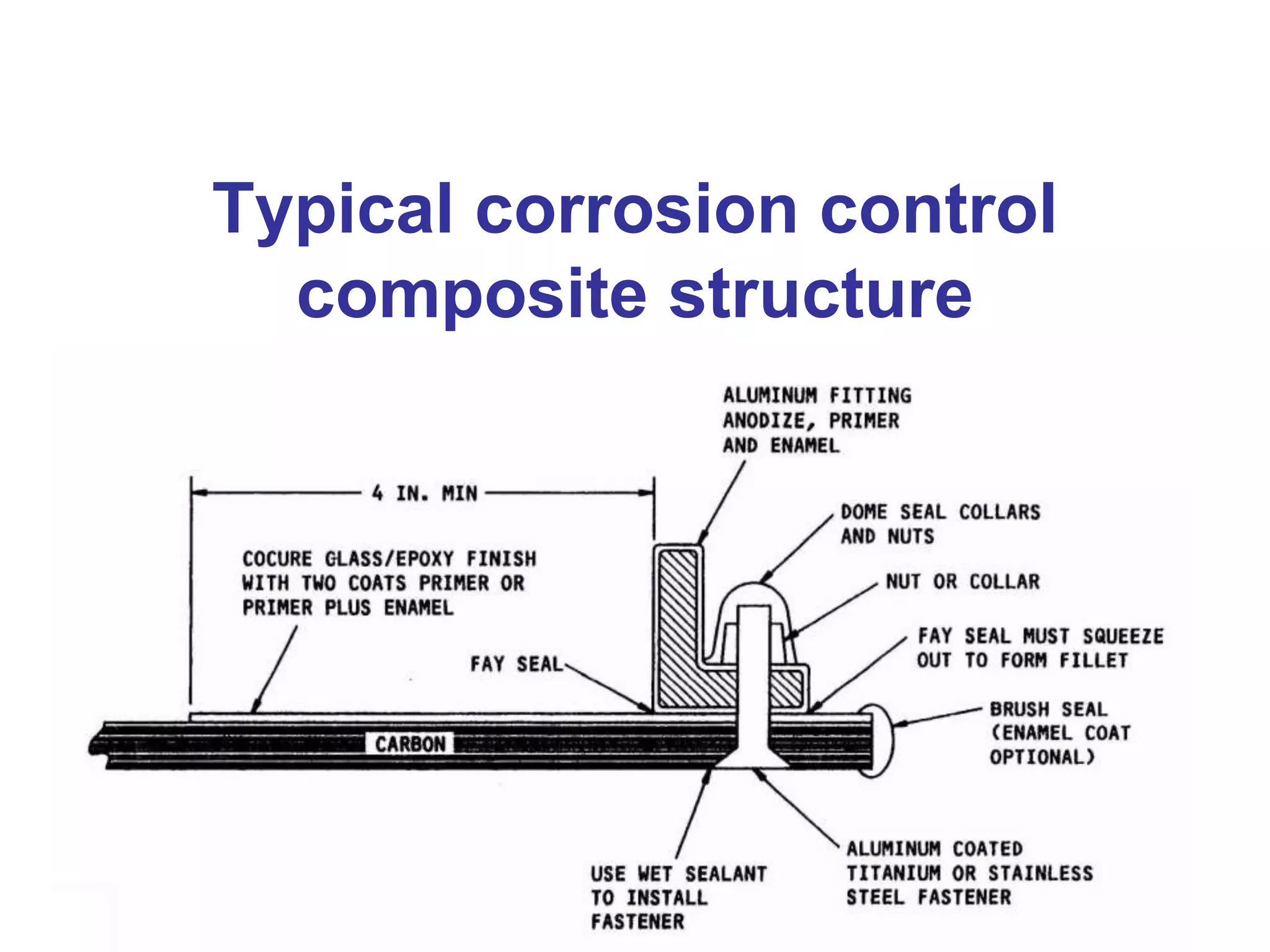

A composite material consists of two or more materials combined through bonding to create a structure with distinct properties. A composite's properties depend on the properties of its individual materials, their relative amounts, sizes, shapes, orientations, and bonding. There are three main classes of composites: laminate, particulate, and fiber reinforced. Fiber reinforced plastics are the most commonly used composite in aviation due to their high strength to weight ratio. They consist of resin and high strength fibers. Composites provide benefits like weight reduction, strength customization, and corrosion resistance compared to metals, but also have disadvantages like difficulty in inspection and repair. Proper material selection and structural design are important considerations for composite structures.