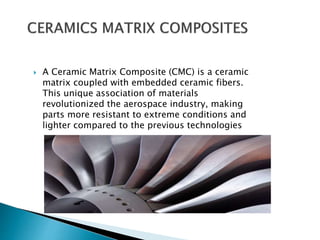

This document discusses different types of composite materials, including polymer matrix composites, metal matrix composites, and ceramic matrix composites. It defines composite materials as combinations of two materials with different physical properties to create a specialized material. It provides details on the composition, properties, and applications of each composite type. The key advantages of composites are their high strength to weight ratio and ability to be tailored for specific mechanical properties.