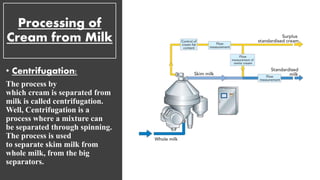

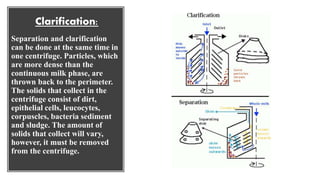

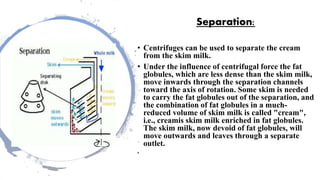

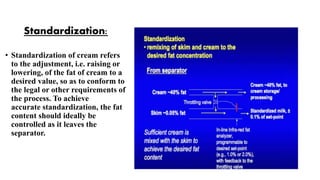

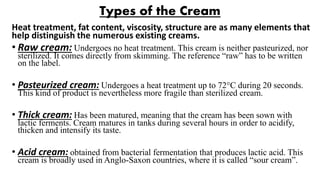

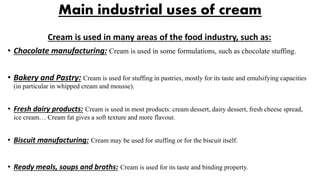

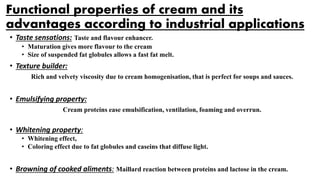

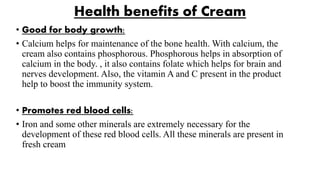

This document discusses cream, including its processing, types, uses, and health benefits. It describes how cream is separated from milk through centrifugation and standardized to a desired fat content. Common types include pasteurized, thick, and acid cream. Cream has various industrial uses in foods like chocolate, bakery products, and ready meals due to its taste, texture, and emulsifying properties. Cream provides health benefits as well, as it contains important vitamins, minerals, and fat that support bone, eye, brain, and heart health.