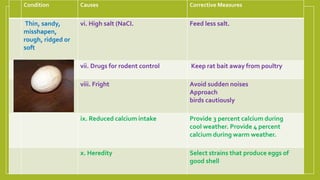

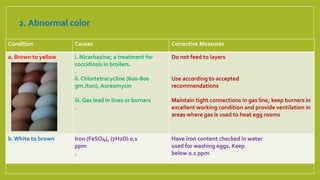

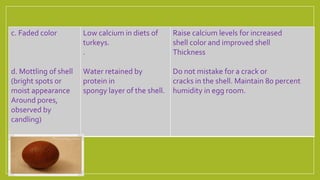

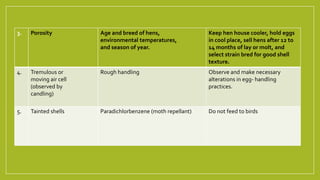

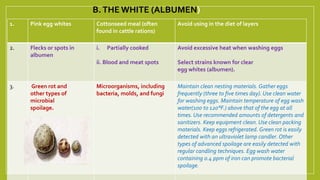

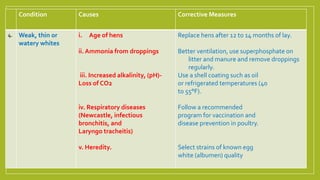

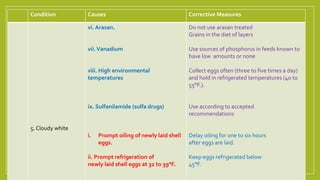

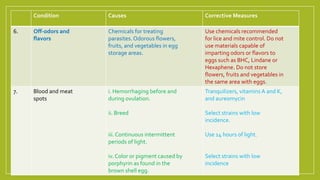

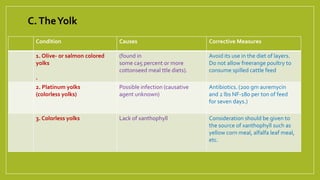

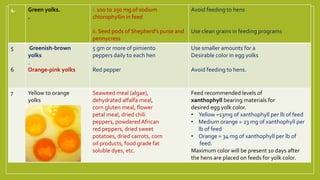

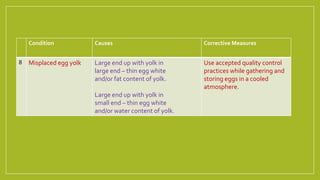

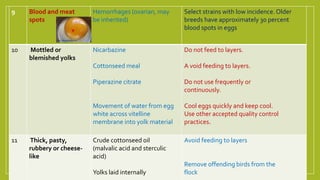

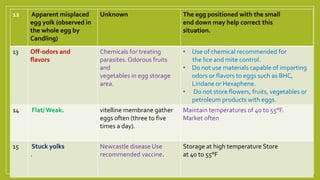

This document discusses factors that affect egg quality, including genetics, feed quality, environment, age of hens, and diseases. It provides examples of problems with shell quality, egg white quality, and yolk quality, along with the potential causes and recommended corrective measures. Some of the key factors mentioned are age of hens, calcium intake, temperature, humidity, handling practices, and preventing diseases through vaccination. Replacing older hens or molting hens is recommended to improve egg quality over time.