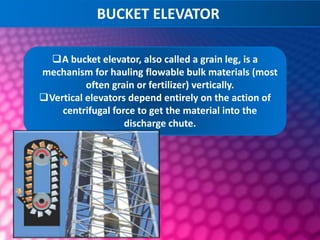

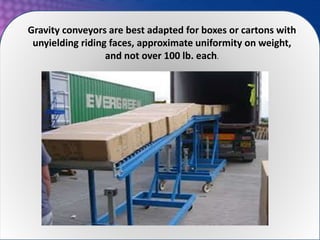

This document discusses different types of conveyor systems used to move materials from one location to another. It describes screw conveyors, flight and apron conveyors, bucket elevators, and pneumatic and hydraulic conveyors. It also discusses considerations for handling unit loads and ensuring peak performance of conveyor systems through proper inspection, maintenance and monitoring.