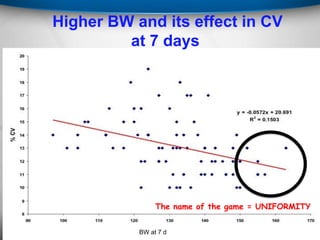

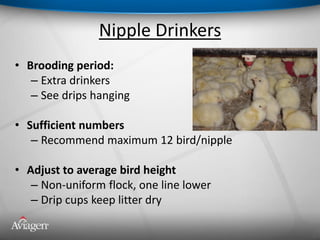

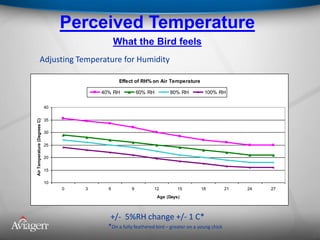

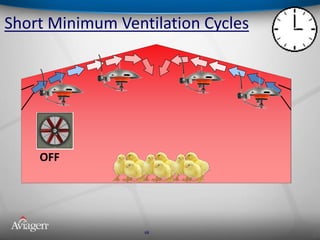

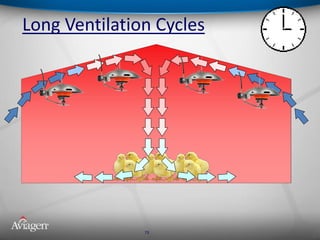

This document discusses broiler chicken management. It begins by explaining the importance of proper brooding management for chick development and performance. It emphasizes establishing feeding and drinking behaviors early. The document then discusses brooding layout, including stocking density and distribution of feeders and drinkers. It stresses the importance of temperature, humidity, ventilation and the bird's perceived thermal comfort. Longer ventilation cycles and minimizing fluctuations are recommended over short cycles. The document provides targets for water quality, lighting programs, and feed specifications. Overall it emphasizes that matching the environment to the bird's requirements is key for successful broiler production.