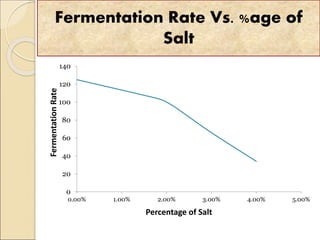

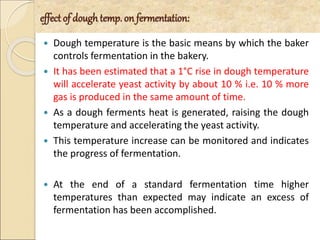

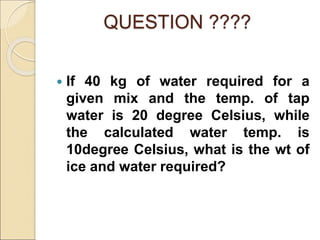

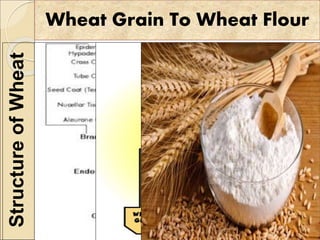

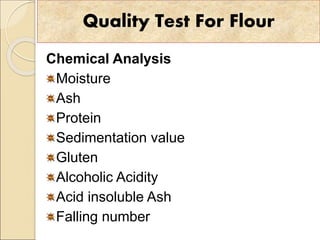

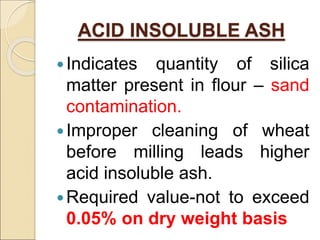

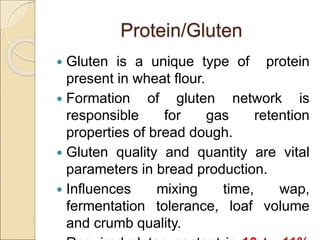

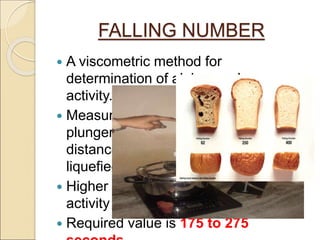

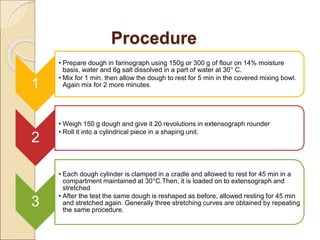

The document discusses the key ingredients and processes involved in bread making. It provides information on various flour parameters like moisture content, protein content, ash content, and how they impact bread quality. It also discusses the roles of other ingredients like water, salt, sugar and yeast. Water is important for gluten formation and fermentation. Salt strengthens gluten and improves flavor while sugar feeds the yeast. Yeast is the main leavening agent and produces carbon dioxide through fermentation. The document outlines the fermentation process and optimal conditions for yeast activity.

![Forms Of Yeast:

Compressed yeast: also called fresh yeast.

It is moist and perishable and is preferred by

professional bakers.

Active dry yeast: is a dry, granular form of yeast.

It must be rehydrated in 4 times its weight of warm

water [about 110°F (43°C)] before use.

Instant active dry yeast: is also a dry granular form of

yeast, but it does not have to be dissolved in water

before use.

Note: Dry yeast are good choice for longer term storage.](https://image.slidesharecdn.com/breadtechnology-201006151818/85/Bread-technology-48-320.jpg)