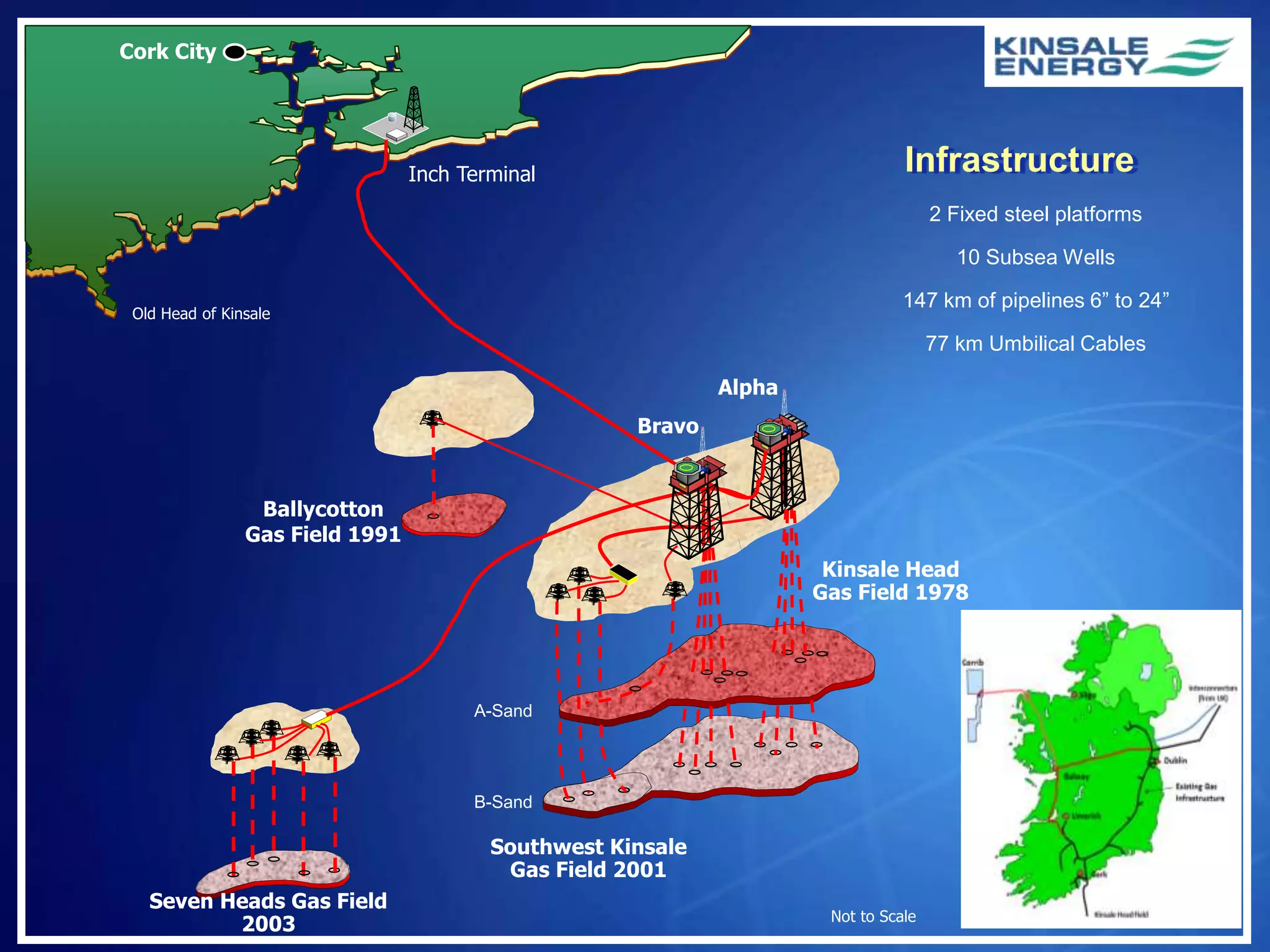

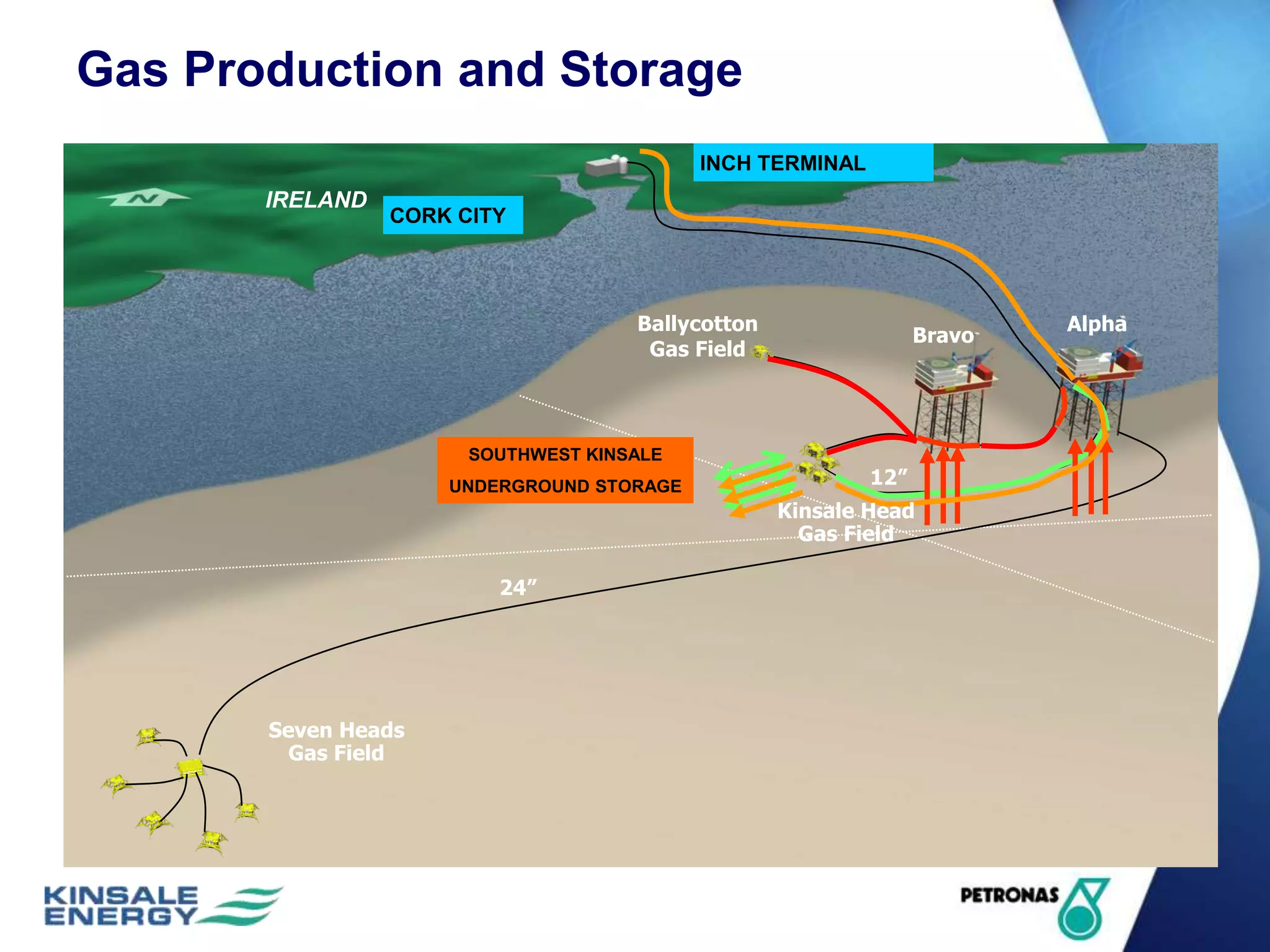

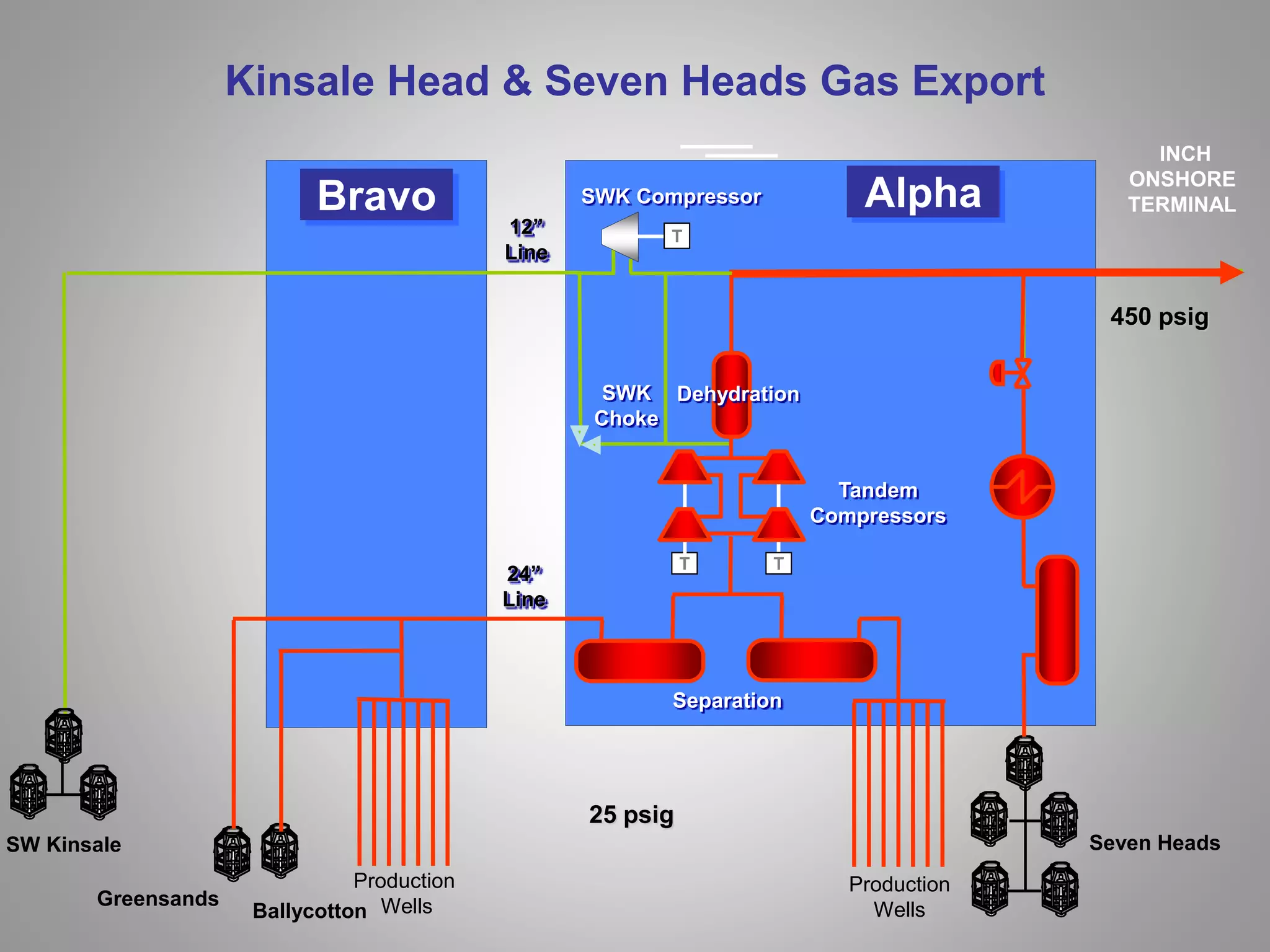

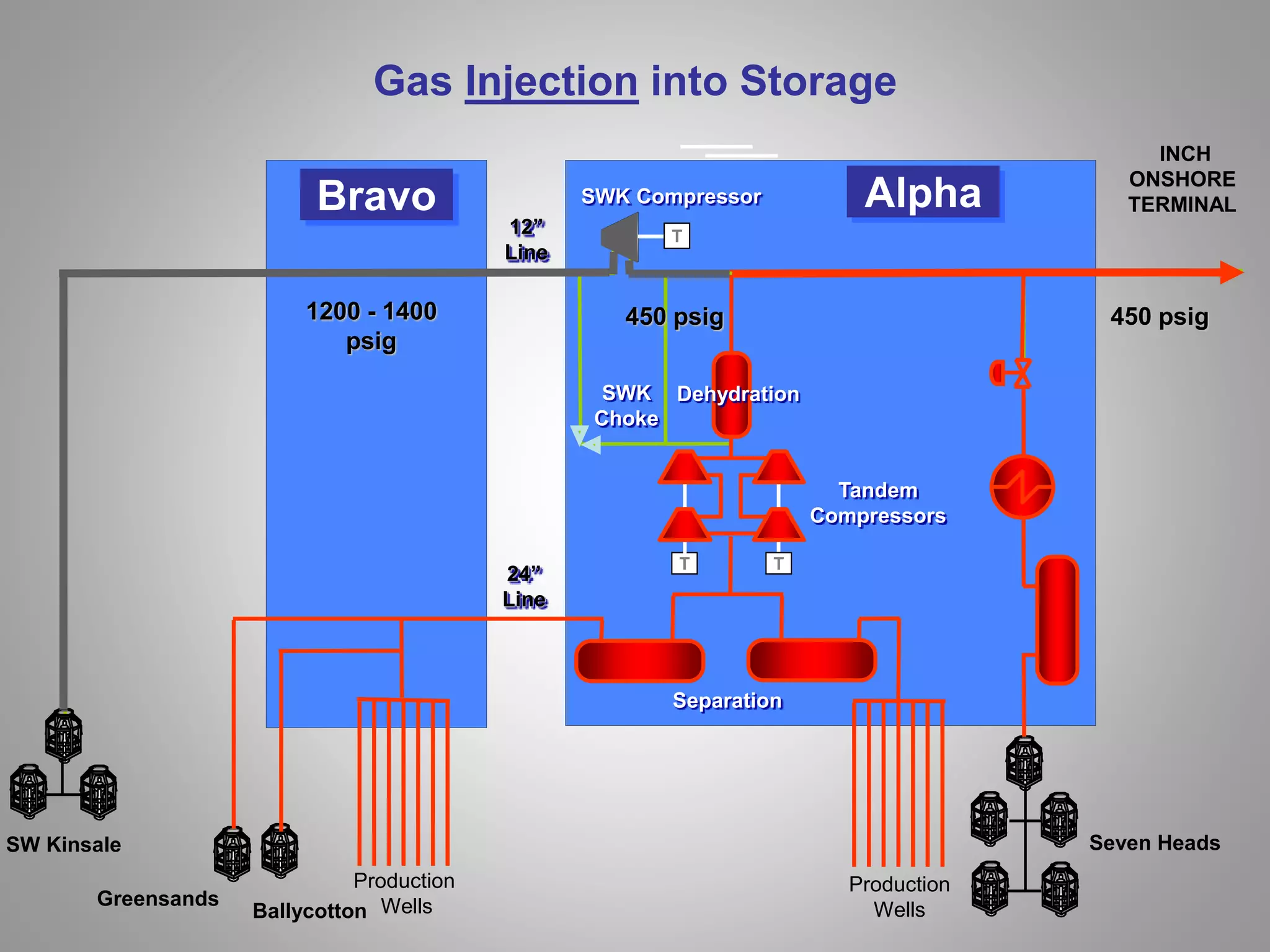

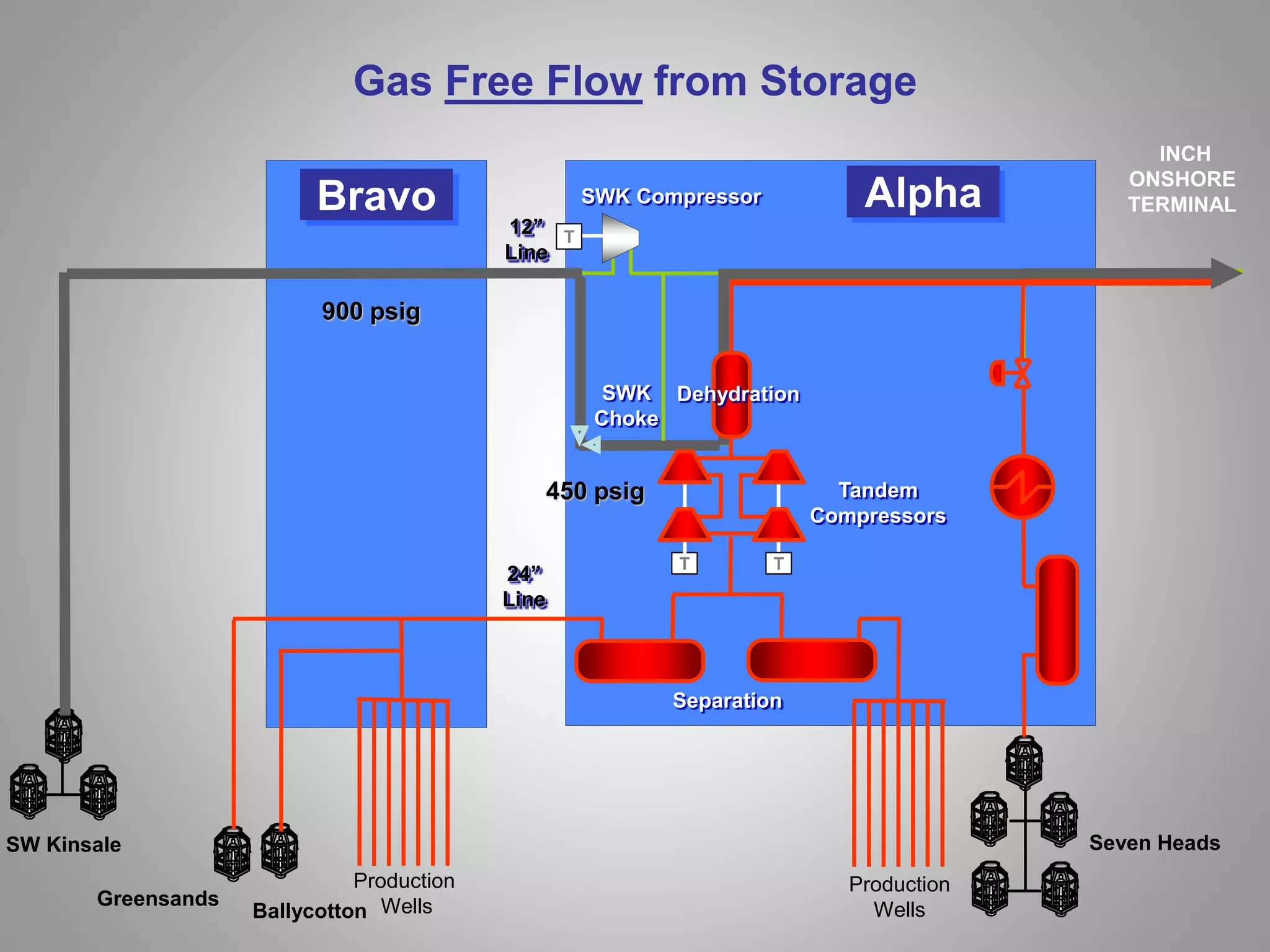

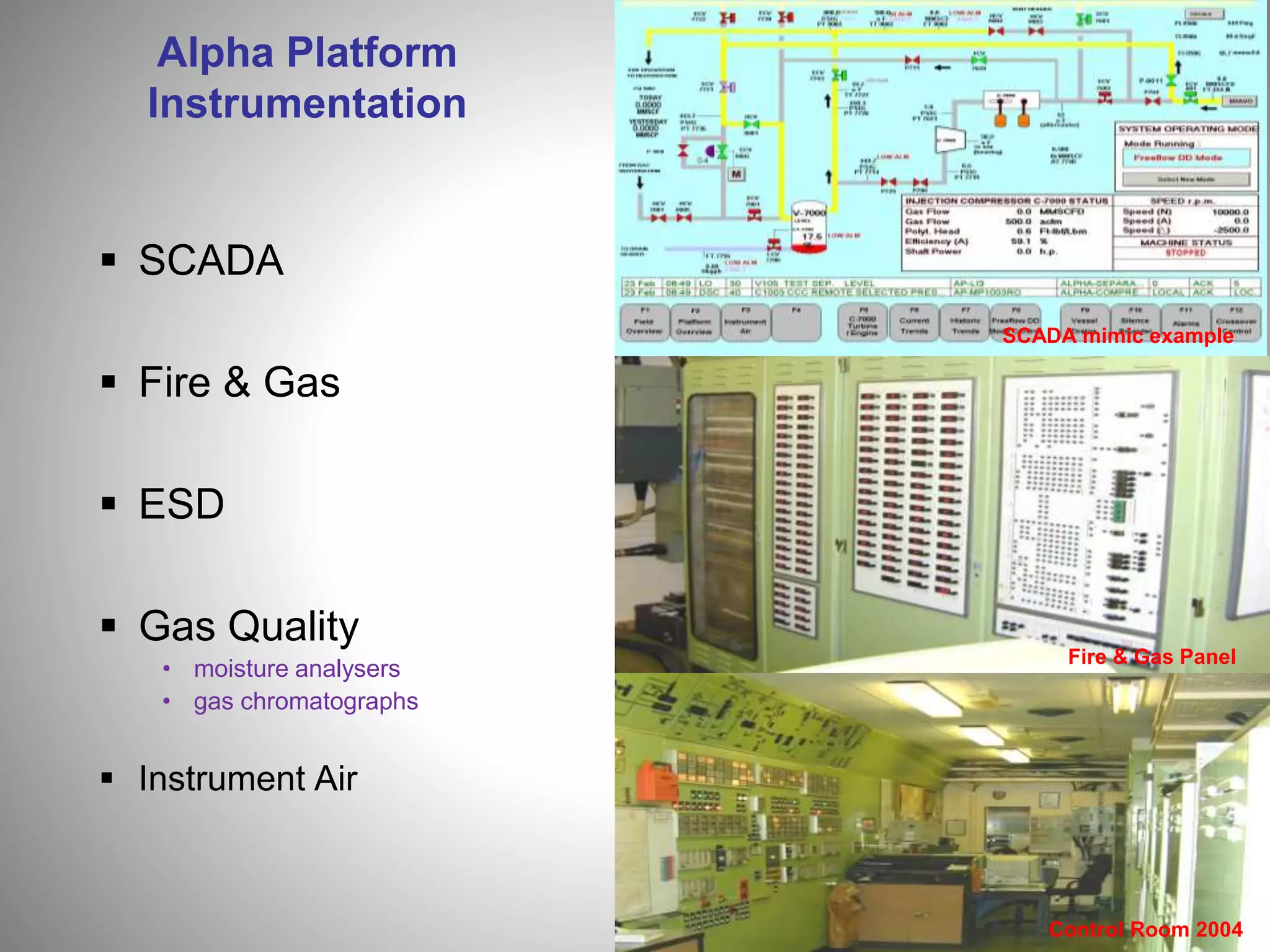

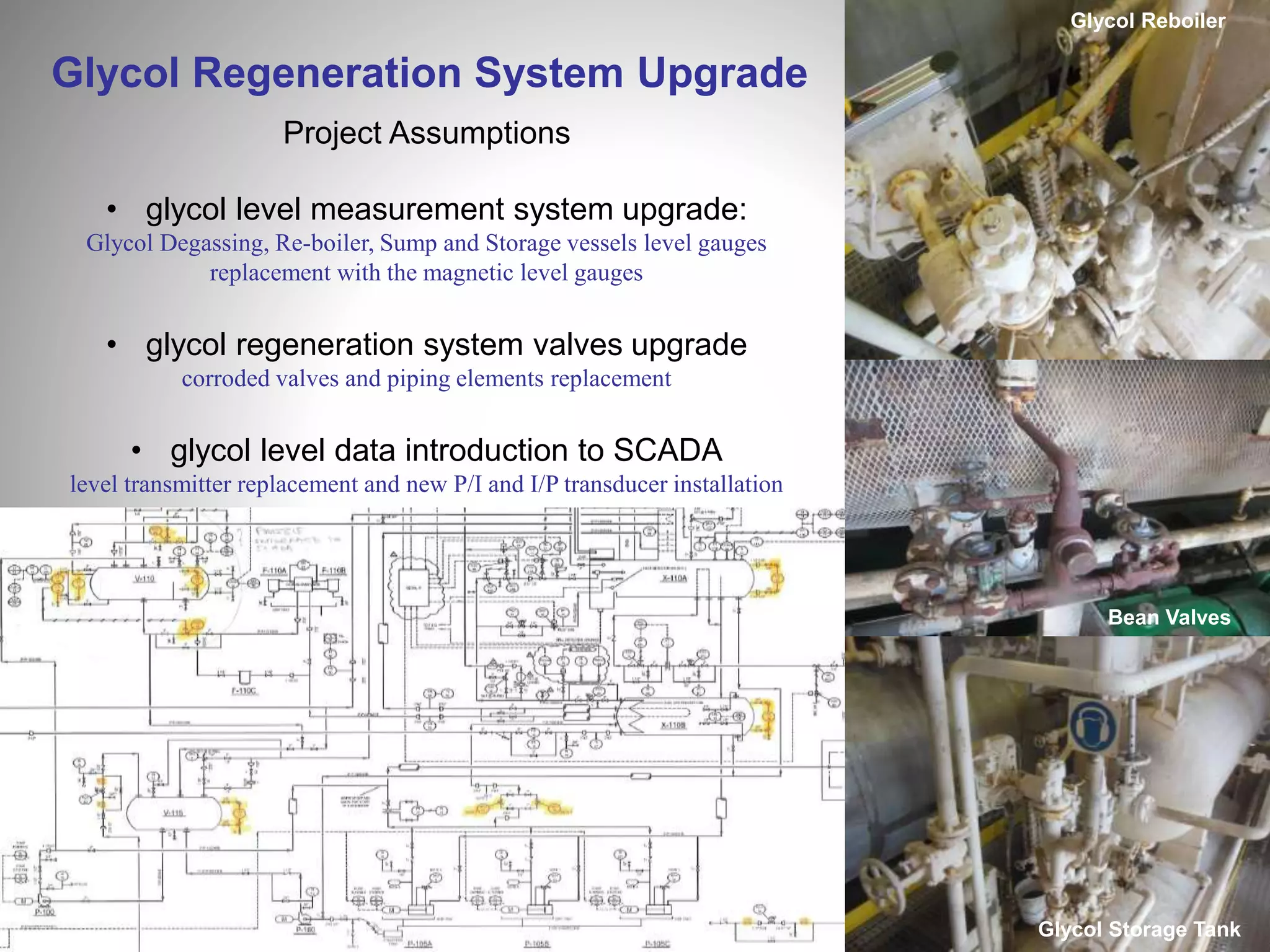

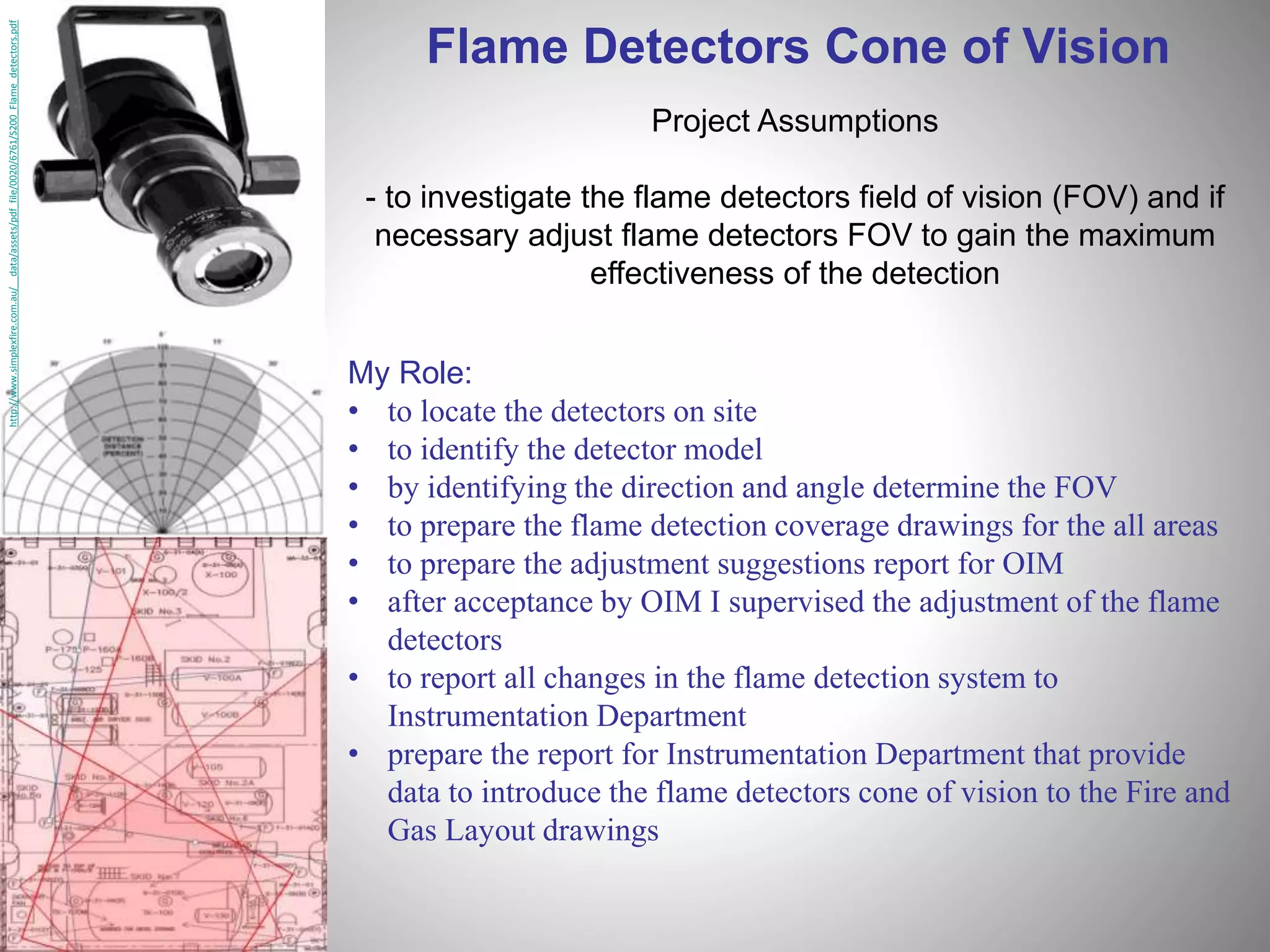

Piotr Blaut completed a work placement with Kinsale Energy Ltd from March to May 2015. He gained experience working on offshore platforms and projects. Some of the projects he assisted with included upgrading the glycol regeneration system by replacing old valves and instruments, updating the fire and gas detection system by inspecting detectors and modifying drawings, and adjusting flame detectors' fields of vision to improve safety coverage. The placement provided opportunities for Piotr to learn about offshore gas production and safety processes.