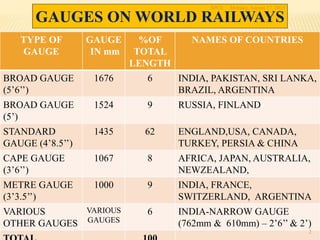

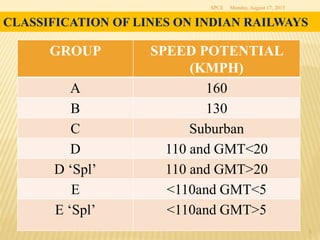

The document discusses various aspects of railway track design and maintenance. It describes the different railway track gauges used worldwide and in India. It then covers classification of railway lines in India based on speed potential. The major areas of responsibility for civil engineers are listed as permanent way, works, and bridges. Key features of permanent way such as rails, sleepers, ballast and their functions are explained. Track maintenance methods like packing and geometry measurement are outlined. Finally, factors influencing alignment, curvature, super elevation and gradients are summarized.