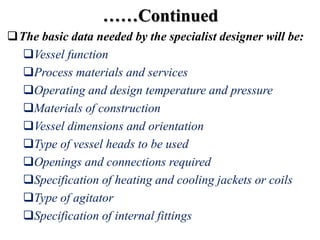

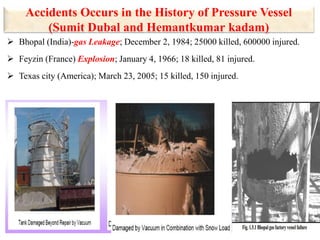

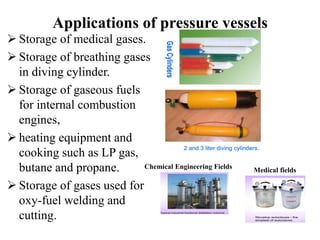

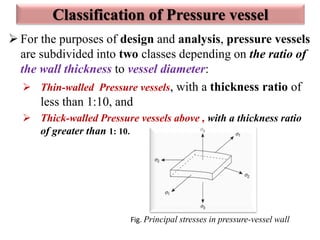

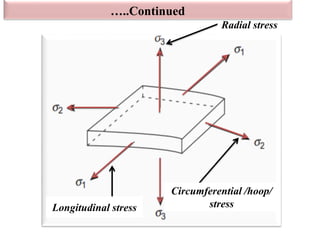

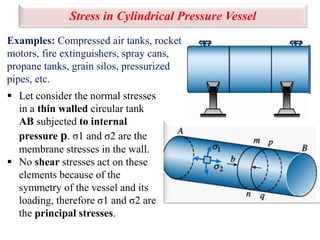

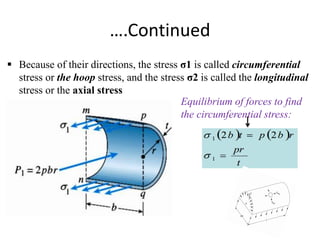

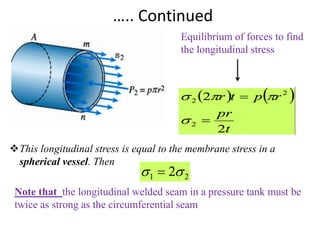

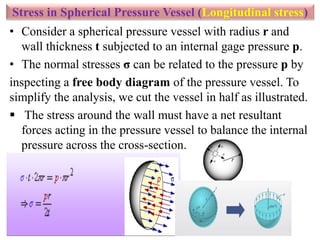

The document provides information about mechanical design of pressure vessels. It begins with introducing pressure vessels and their importance in chemical engineering fields. Then it discusses factors to consider in pressure vessel design like maximum pressure, temperature, material selection and thickness. It also covers stresses in cylindrical and spherical pressure vessels and standards for pressure vessel design like ASME and API codes. Pressure vessel failures can occur due to improper material selection, defects in design/fabrication or corrosion. The document aims to educate chemical engineering students on basic concepts of pressure vessel design.