The document discusses the design and stress analysis of a pressure vessel using ANSYS, focusing on elements such as shell, dish end, and operating manholes based on ASME standards. It highlights the importance of material selection and the implications of pressure loading on vessel integrity, detailing the design process, stress analysis methods for both thin and thick-walled vessels, and emphasizes the significance of adhering to safety standards. Conclusions underscore the necessity for rigorous specification requirements and the importance of component selection over the design of individual parts.

![A. Dhanaraj Int. Journal of Engineering Research and Applications www.ijera.com

ISSN : 2248-9622, Vol. 5, Issue 4, ( Part -6) April 2015, pp. 32-38

www.ijera.com 35 | P a g e

mt 3

1036.5

1834

3

123

3

123

L

= 1916 mm

III. ANALYSIS OF PRESSURE VESSEL

Structural Results

Table.5: Structural Supports

Name Fixed Support Shell

Material Structural Steel

Mass(kg) 109.69

Volume(m3

) 1.4×10-2

Type Fixed Surface

Reaction Force 1.71×10-3

N

Reaction Force Vector

[-1.71×10-3

Nx, 1.16×10-

7

Ny,

3.67×10-9

Nz

Reaction Moment 1.81×10-5

N·m

Reaction moment vector

[1.81×10-5

N·m x,

3.16×10-9

N·m y,

1.06×10-7

N·m z]

Table.6: Structural results

Fig.4: "Equivalent Stress" Contours

Fig.5: "Total Deformation" Contours

Ellipsoidal Dish End

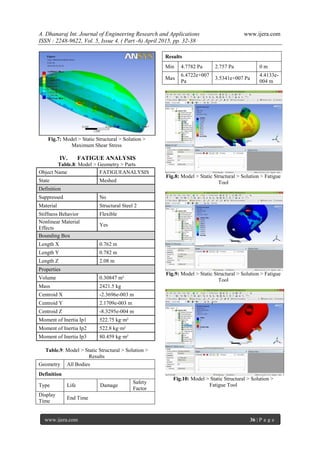

Table.7: Model > Static Structural > Solution >

Results

Object

Name

Equivalent

Stress

Maximu

m Shear

Stress

Total

Deformation

State Solved

Scope

Geometr

y

All Bodies

Definition

Type

Equivalent

(Von-mises)

Stress

Max

Shear

Stress

Total

Deformation

Display

Time

Solved Solved Solved

Results

Min

3.101e+006

Pa

1.613e+006

Pa

0 m

Max

3.137e+007

Pa

1.696e+007

Pa

4.1032e-005

m

Fig.6: Model > Static Structural > Solution >

Equivalent Stress

Name Scope Min Max

Equivalent

Stress

Model 8.6×106

Pa 3.5×107

Pa

Maximum

Shear

Stress

Model

4.96×106

Pa

1.87×107

Pa

Total

Deformation

Model 0.0 m

4.27×10-5

m](https://image.slidesharecdn.com/f504063238-150428014111-conversion-gate02/85/Design-Stress-Analysis-of-a-Cylinder-with-Closed-ends-using-ANSYS-4-320.jpg)

![A. Dhanaraj Int. Journal of Engineering Research and Applications www.ijera.com

ISSN : 2248-9622, Vol. 5, Issue 4, ( Part -6) April 2015, pp. 32-38

www.ijera.com 38 | P a g e

- The design of pressure vessel is initialized with

the specification requirements in terms of

standard technical specifications along with

numerous requirements that lay hidden from the

market.

- The design of a pressure vessel is more of a

selection procedure, selection of its components

to be more precise rather designing each and

every component.

- The pressure vessel components are merely

selected, but the selection is very critical, a slight

change in selection will lead to a different

pressure vessel al- together from what is aimed to

be designed.

- It is observed that all the pressure vessel

components are selected on basis of available

ASME standards and the manufactures also

follow the ASME standards while manufacturing

the components. So that leaves the designer free

from designing the components. This aspect of

Design greatly reduces the Development Time

for a new pressure vessel.

REFERENCES

[1] BHPV manual on Multilayer Pressure

Vessels.

[2] Brownell and Young, "Process Equipment

Design" Chapter 7, Chapter 13, Chapter 14

and Chapter 15. Seely,

[3] F.B., and Smith, A.O., "Advanced Mechanics

of Materials" Wiley, Newyork, Chapter 10.

[4] John F.Henvey “Pressure Vessel Design -

Nuclear and Chemical Applications" An

East-west Edition, Newyork, Chapter 5 and

Chapter 7.

[5] Henry H.Bednar “Pressure Vessel Code

Book", Chapter 11.

[6] Jasper, T.M and Scudder, C.M AIChE

Transactions, PP885 -909.

[7] Fino, A.F., “Economic Considerations for

High Pressure vessel Design" pp-101-104.

[8] Fratcher, G.E: New alloys for Multilayer

Vessels" Vol 33, No.11.

[9] Jasper, T.M and Scudder, C.M “Multilayer

Construction of Thick-wall Pressure

Vessels" Volume 37.

[10] Jawad, Maan H., "Wrapping Stress and Its

Effect on strength of Concentrically Formed

Plywaals," Paper No72-PVP7.](https://image.slidesharecdn.com/f504063238-150428014111-conversion-gate02/85/Design-Stress-Analysis-of-a-Cylinder-with-Closed-ends-using-ANSYS-7-320.jpg)