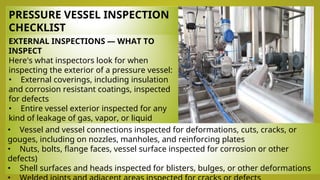

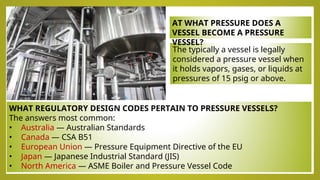

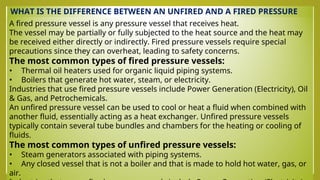

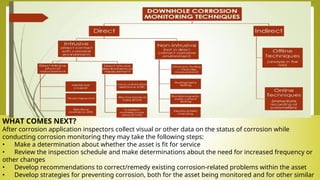

The document provides an overview of pressure vessels, including their definitions, types, and safety considerations, along with the importance of regular inspections to prevent catastrophic failures. It emphasizes the role of various inspection methods and modern technologies like drones in enhancing safety, efficiency, and data quality during inspections. Additionally, it discusses the implications of corrosion monitoring, highlighting its significance in maintaining the integrity of pressure vessels and reducing associated costs.