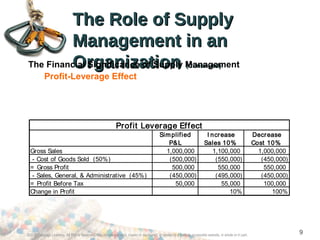

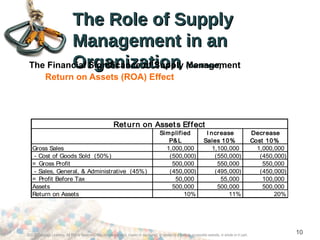

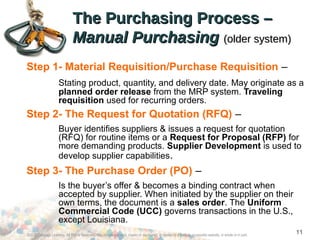

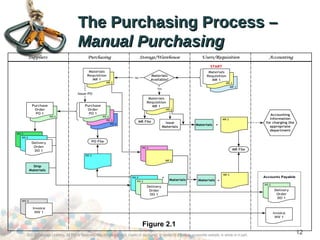

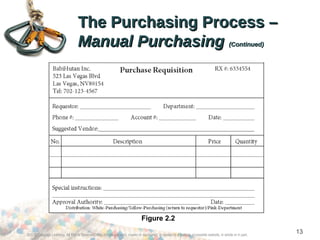

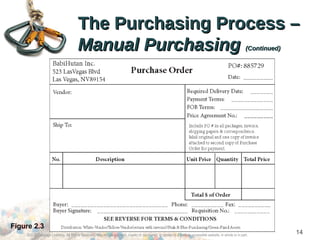

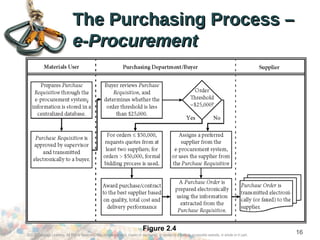

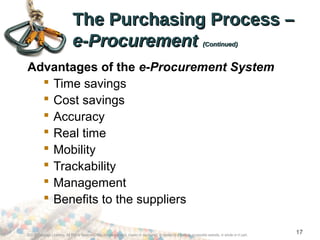

This document provides an overview of key concepts in supply chain management and purchasing. It outlines learning objectives related to understanding the strategic role of supply management, the purchasing process, sourcing decisions, supplier selection, and global sourcing. The purchasing process is described, including the traditional manual process involving requisitions, requests for quotes, purchase orders, delivery orders, and invoicing. The financial significance of supply management is also discussed in terms of profit leverage, return on assets, and inventory turnover. Figures are included to illustrate the traditional purchasing process.