The document discusses the purchasing function and process. It covers key topics like:

- The importance of purchasing management in procuring materials for production.

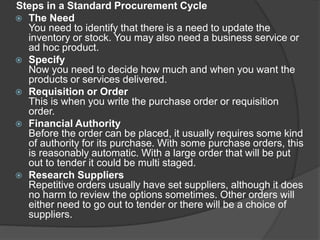

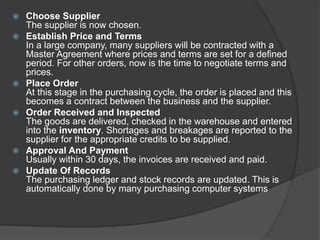

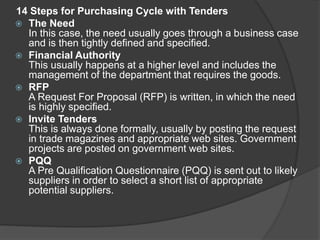

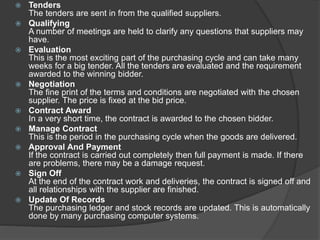

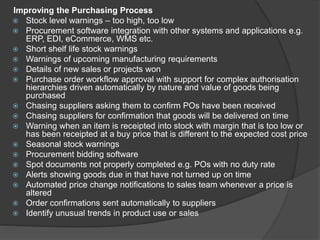

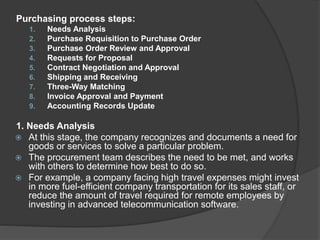

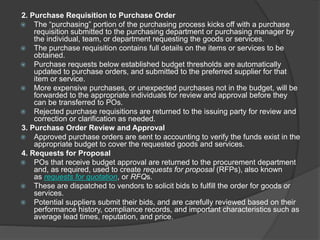

- The purchasing cycle and objectives to obtain materials at the right quality, quantity, time and price.

- The types of purchase decisions organizations make including new purchases, modified re-buys, and straight re-buys.

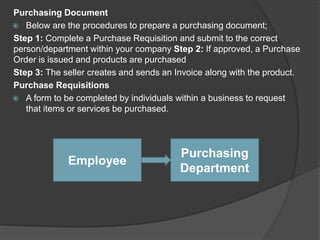

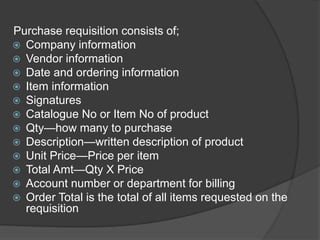

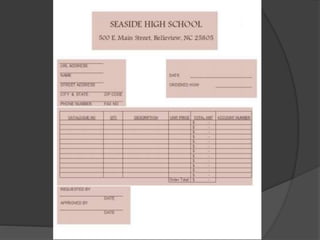

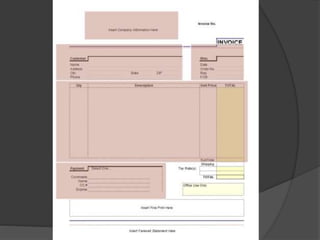

- How purchase orders, requisitions, and invoices are used in the procurement process.

The document provides an overview of best practices for effective purchase management.

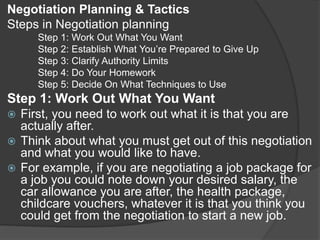

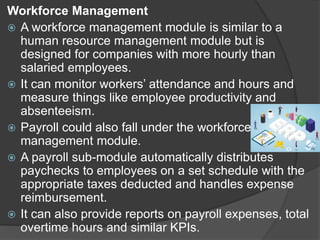

![ You can also allow the requester to change the method of price

and discount transfer for individual purchase requisition lines,

regardless of the price/discount transfer rule that is defined.

Select the Allow manual override per purchase requisition

line option to enable this capability.

On the Item description transfer tab, you can transfer the item

description from the requisition when it originates from an RFQ.

On the Price Tolerance tab, you can define rules to route

approved purchase requisitions back through the review process

when the price of a procurement catalog item increases. Set the

maximum amount that the net amount on a line item on a

purchase requisition can increase between the time when the

purchase requisition is approved and the time when the

purchase order is created. The net amount is calculated by

using the following formula: ([Quantity × (Unit price – Discount) ÷

Price unit] + Purchase miscellaneous charges) × (100 –

Discount percent) ÷ 100 Purchase requisition lines that exceed

the price tolerance that you set are held for manual processing.

The rules that you configure on the Error processing tab

determine how the purchase requisition lines are processed.](https://image.slidesharecdn.com/purchasingsupplychainmanagement-210405084332/85/Purchasing-supply-chain-management-68-320.jpg)

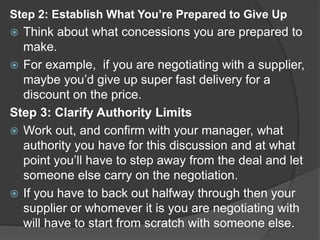

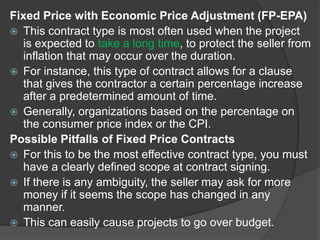

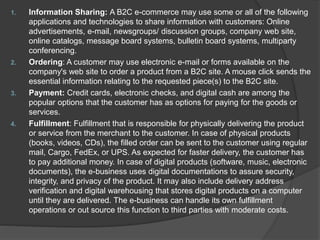

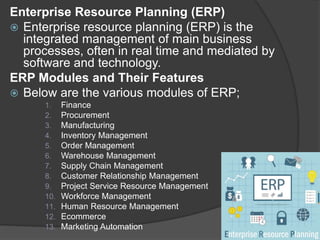

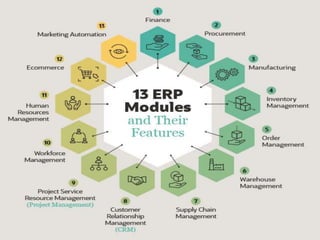

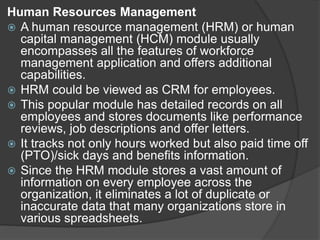

![Ecommerce

Certain ERP vendors offer an ecommerce module for

businesses that want to sell online. This module allows

companies to quickly launch a business-to-business

(B2B) or business-to-consumer (B2C) ecommerce

website.

Leading commerce applications include user-friendly

tools that allow employees to easily add new items,

update product content (item descriptions, titles, specs,

images, etc.) and change the look and feel of the

website.

When the ecommerce application is integrated with other

ERP applications, all payment, order and inventory

information feeds [from the ecommerce module] into the

shared database.

That ensures all transactions are added to the ledger,

out-of-stock items are removed from the site and orders

ship on time.](https://image.slidesharecdn.com/purchasingsupplychainmanagement-210405084332/85/Purchasing-supply-chain-management-153-320.jpg)