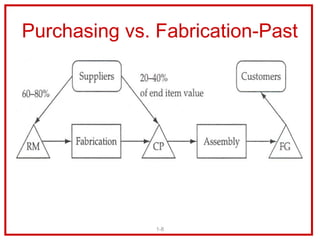

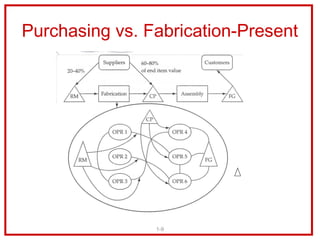

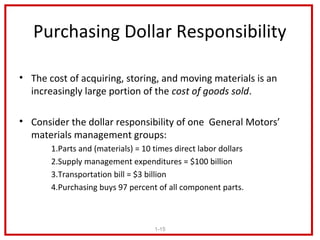

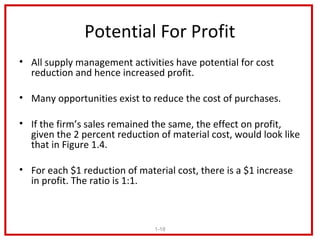

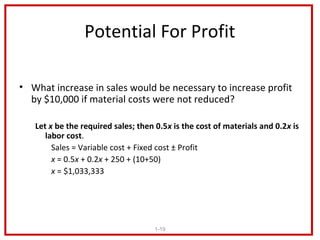

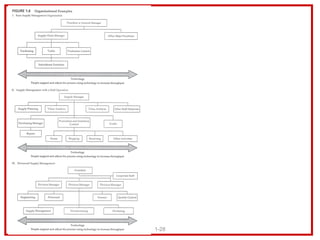

The document discusses the evolution and importance of purchasing and supply management, highlighting its contribution to profitability and relationships with other functional areas. It outlines the historical context, current practices, and future trends, emphasizing the role of technology and centralized purchasing in enhancing efficiency. The text also examines the growing significance of supply management as a professional career and its impact on profit margins.