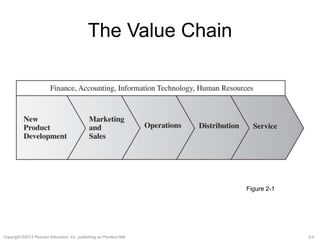

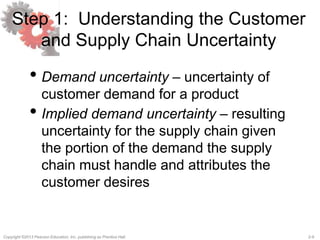

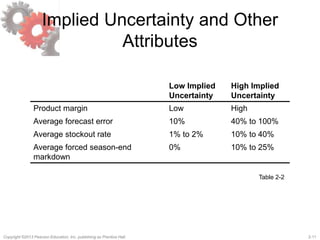

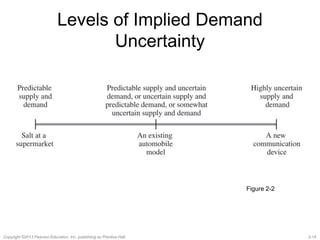

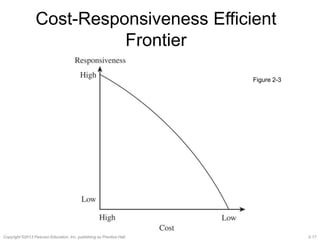

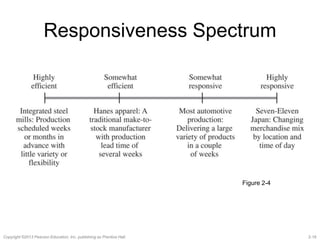

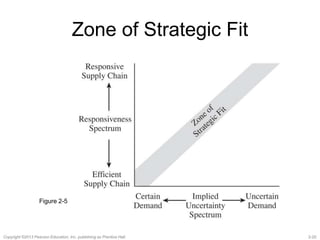

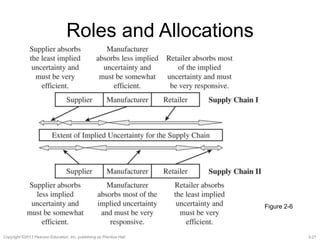

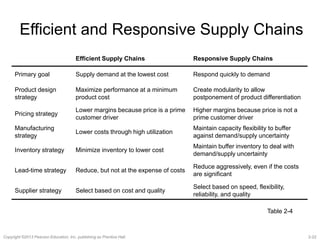

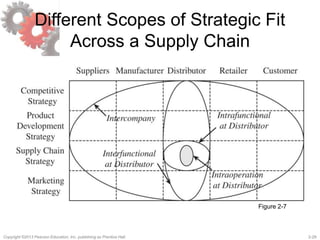

This document discusses achieving strategic fit in supply chain management. It defines strategic fit as having aligned competitive and supply chain strategies. It describes three steps to achieving strategic fit: 1) Understanding customer needs and implied demand uncertainty, 2) Understanding supply chain capabilities, and 3) Aligning supply chain responsiveness with demand uncertainty through strategic roles. The document emphasizes that all functions and stages of the supply chain must work together to execute strategies that support the overall competitive strategy.