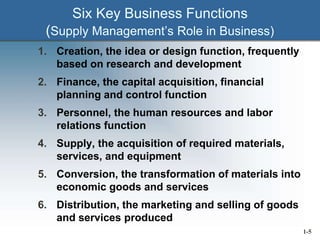

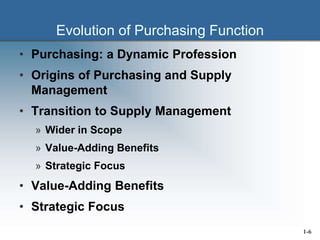

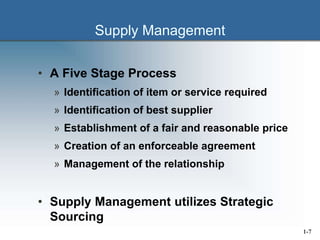

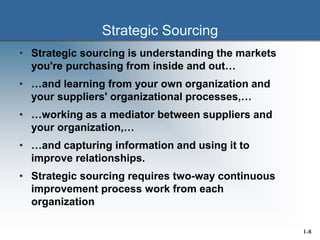

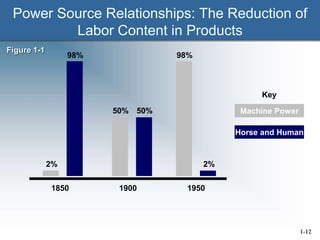

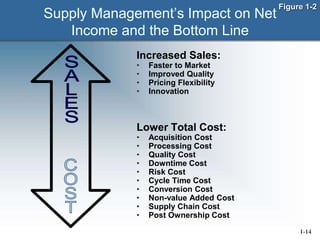

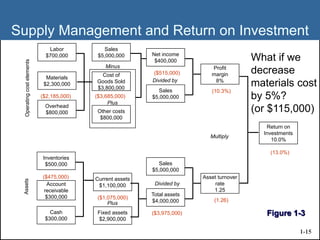

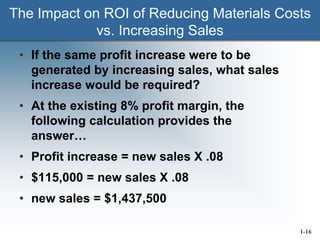

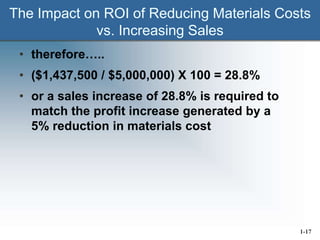

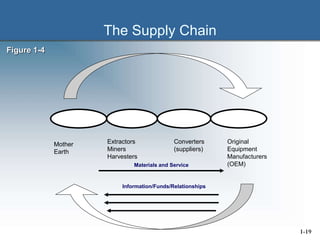

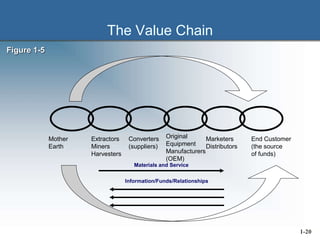

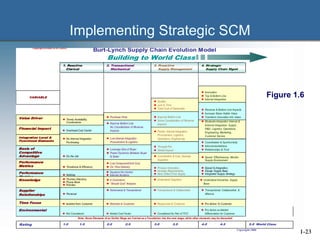

Chapter 1 discusses the evolution and importance of supply management and its impact on organizational success. It details the transition from traditional purchasing to strategic supply management, emphasizing the need for proactive approaches and continuous improvement. Key concepts include the role of supply management in enhancing profitability through cost reduction and efficient resource allocation.