The document discusses key topics in purchasing management including:

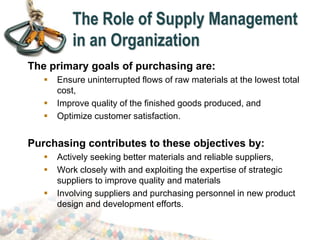

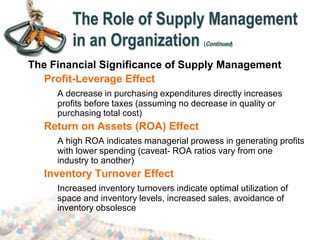

- The role of supply management in ensuring cost efficiency, quality products, and customer satisfaction. Effective supply management can provide competitive advantages.

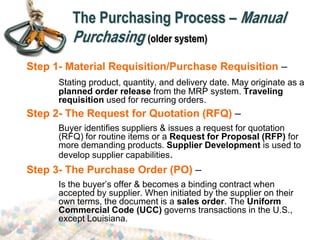

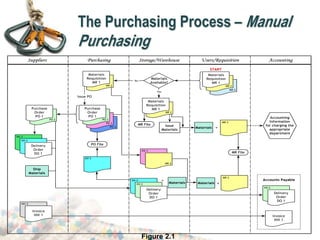

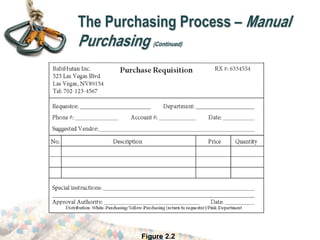

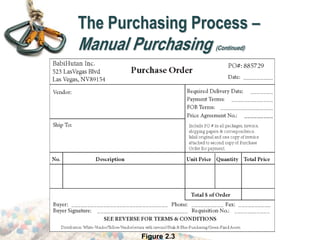

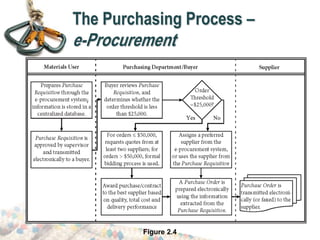

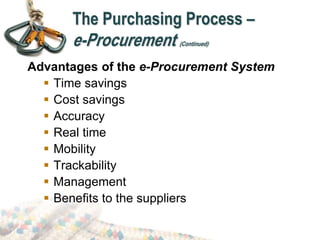

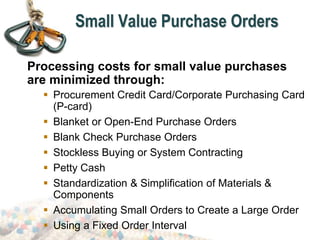

- An overview of the purchasing process, from requisitions to purchase orders. Both manual and e-procurement processes are covered.

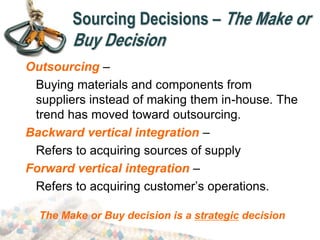

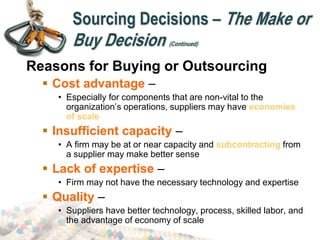

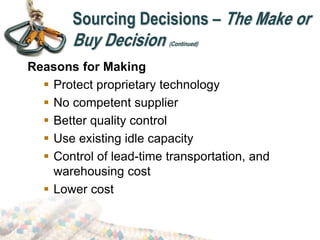

- Factors to consider in sourcing decisions including whether to make or buy materials. Reasons for both insourcing and outsourcing are discussed.

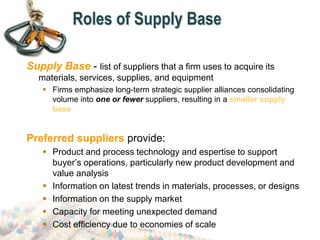

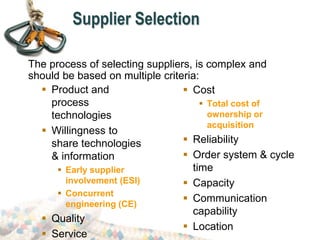

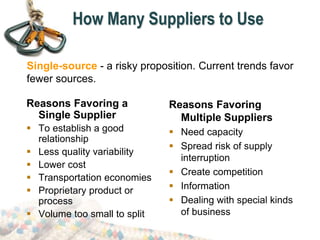

- Criteria for supplier selection focus on cost, quality, service, capacity, technologies, and reliability. Developing strategic supplier partnerships is emphasized.