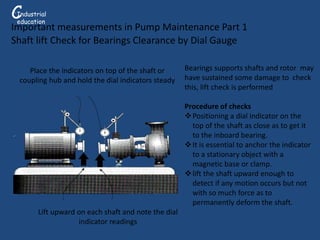

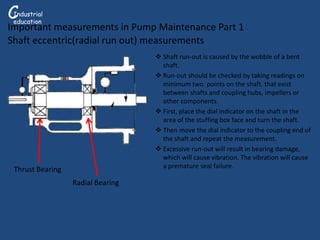

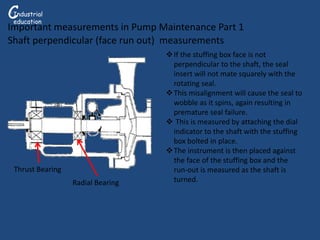

The document outlines key measurements and checks necessary for pump maintenance, focusing on bearing clearance and shaft measurements. It details methods for conducting shaft lift checks, using dial gauges, plastic gauges, and blue matching techniques, as well as measuring shaft deflection and run-out. This is part 1 of a series that will cover additional measurement techniques in future parts.