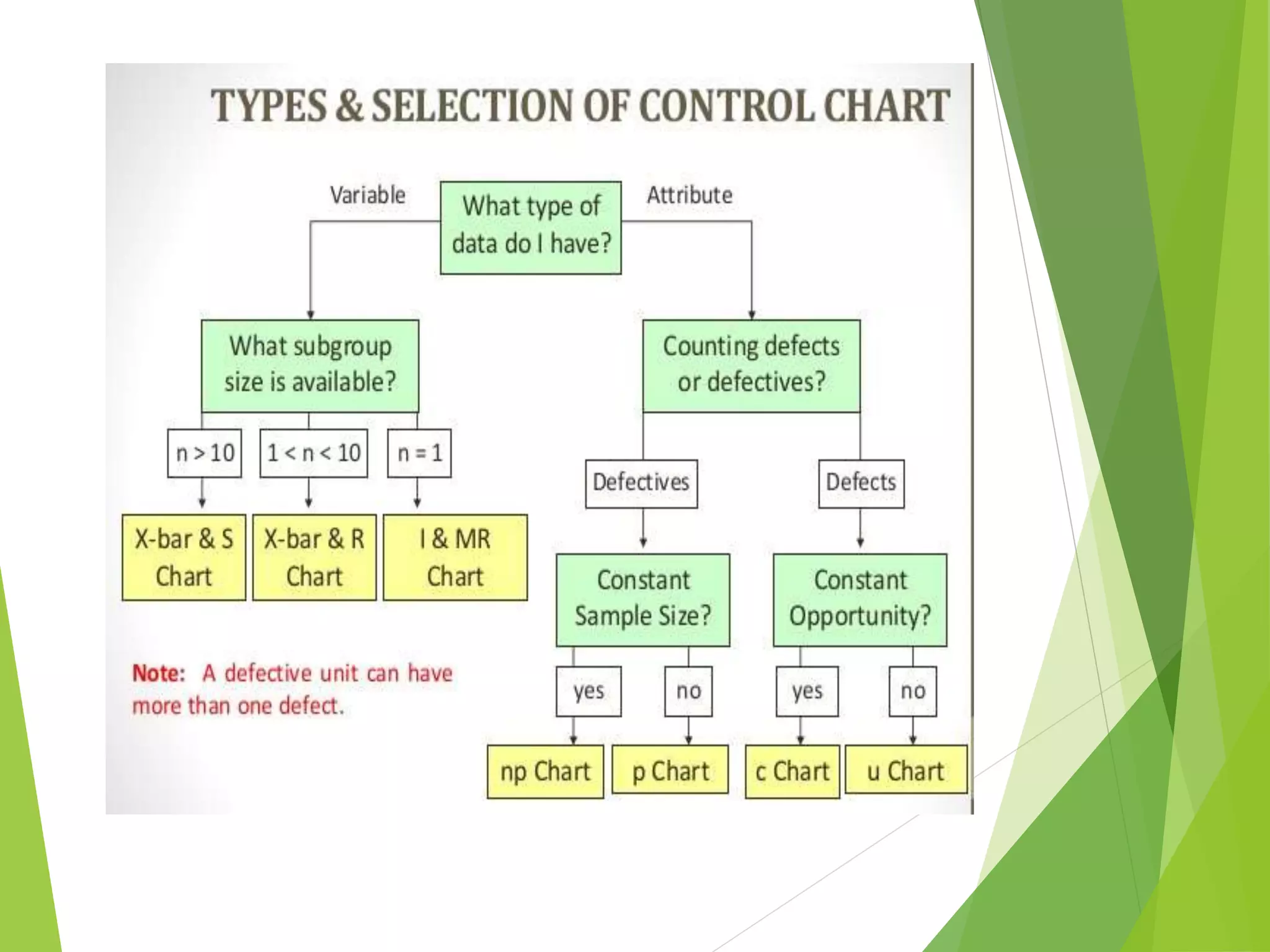

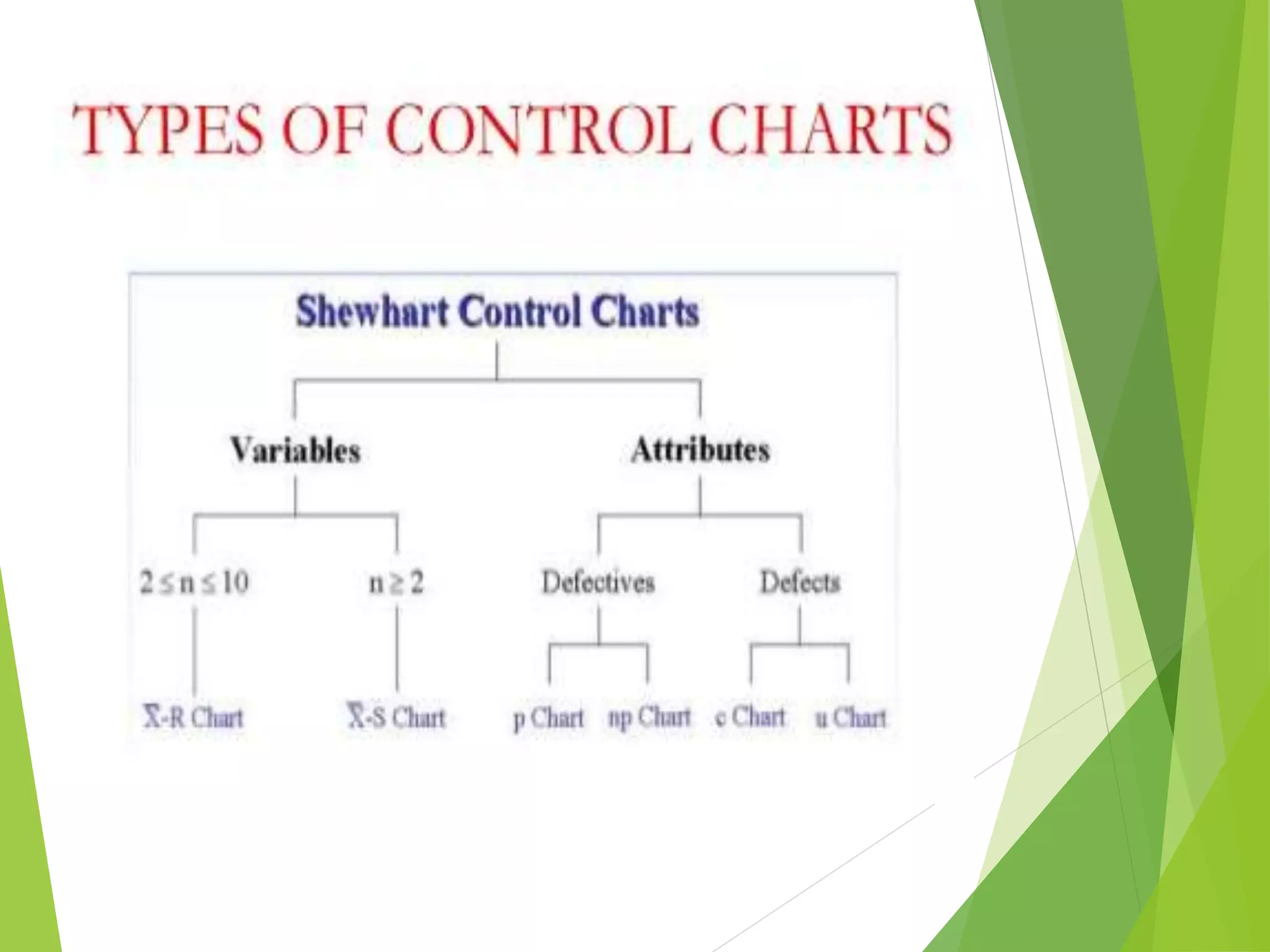

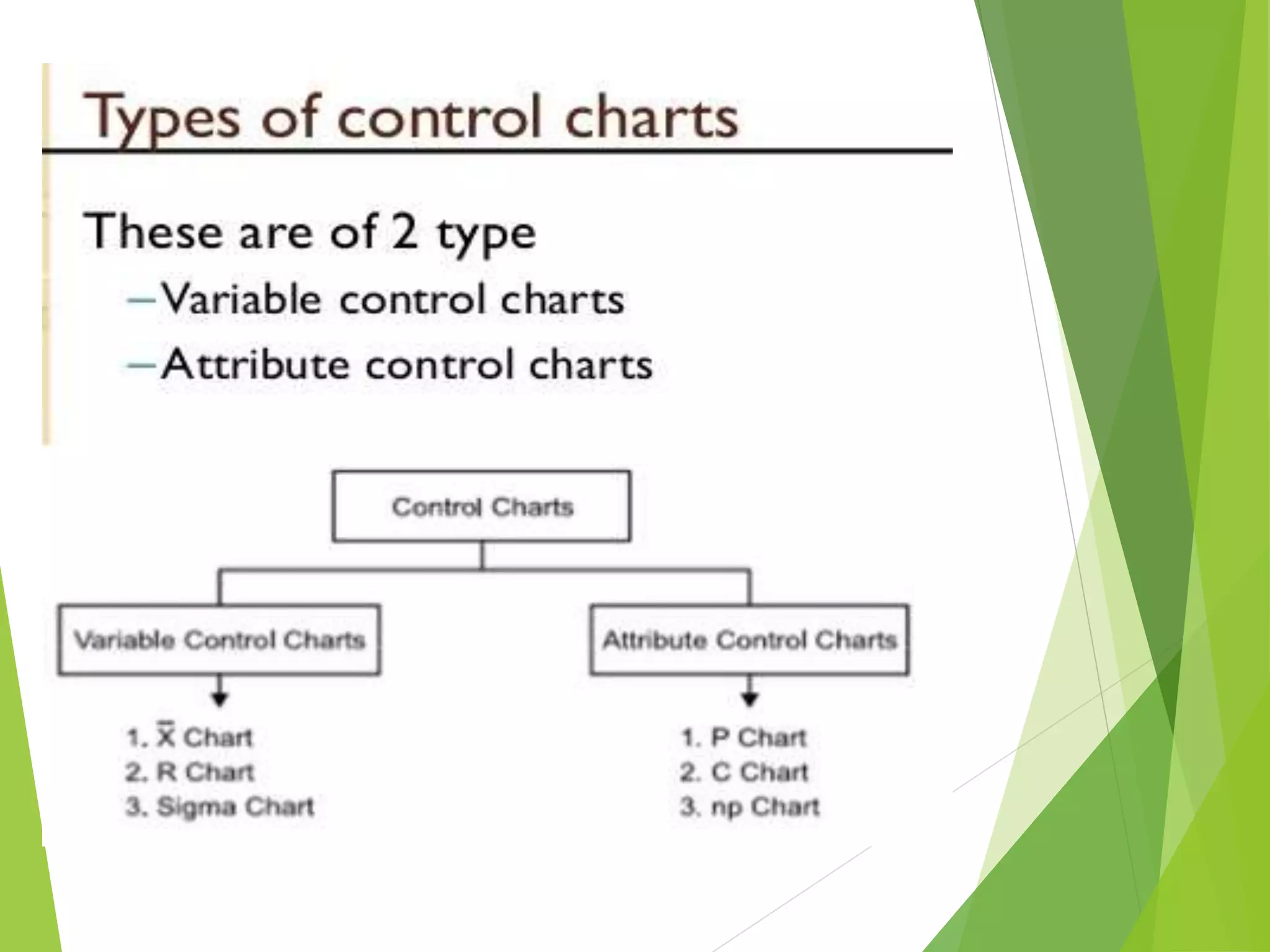

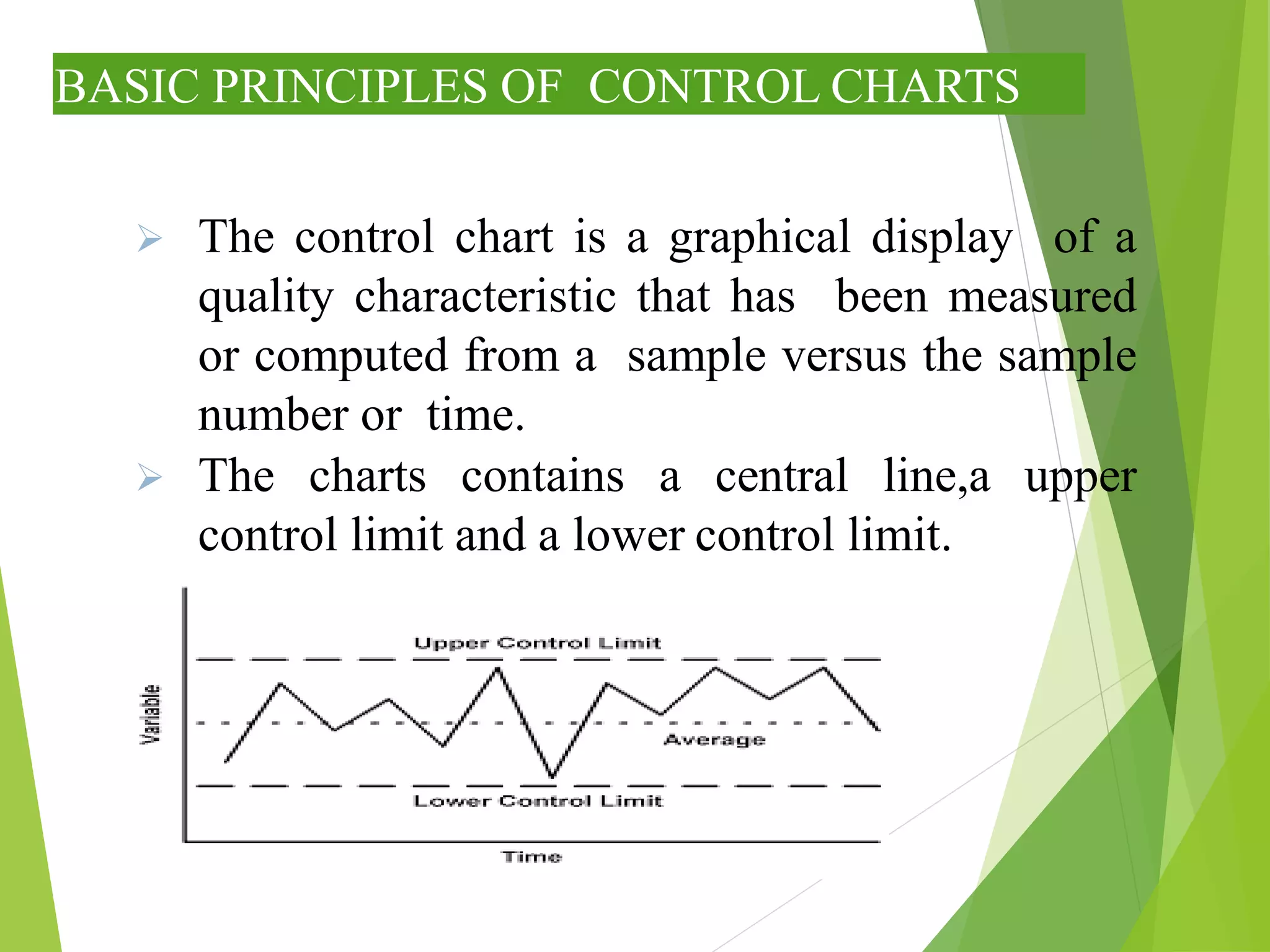

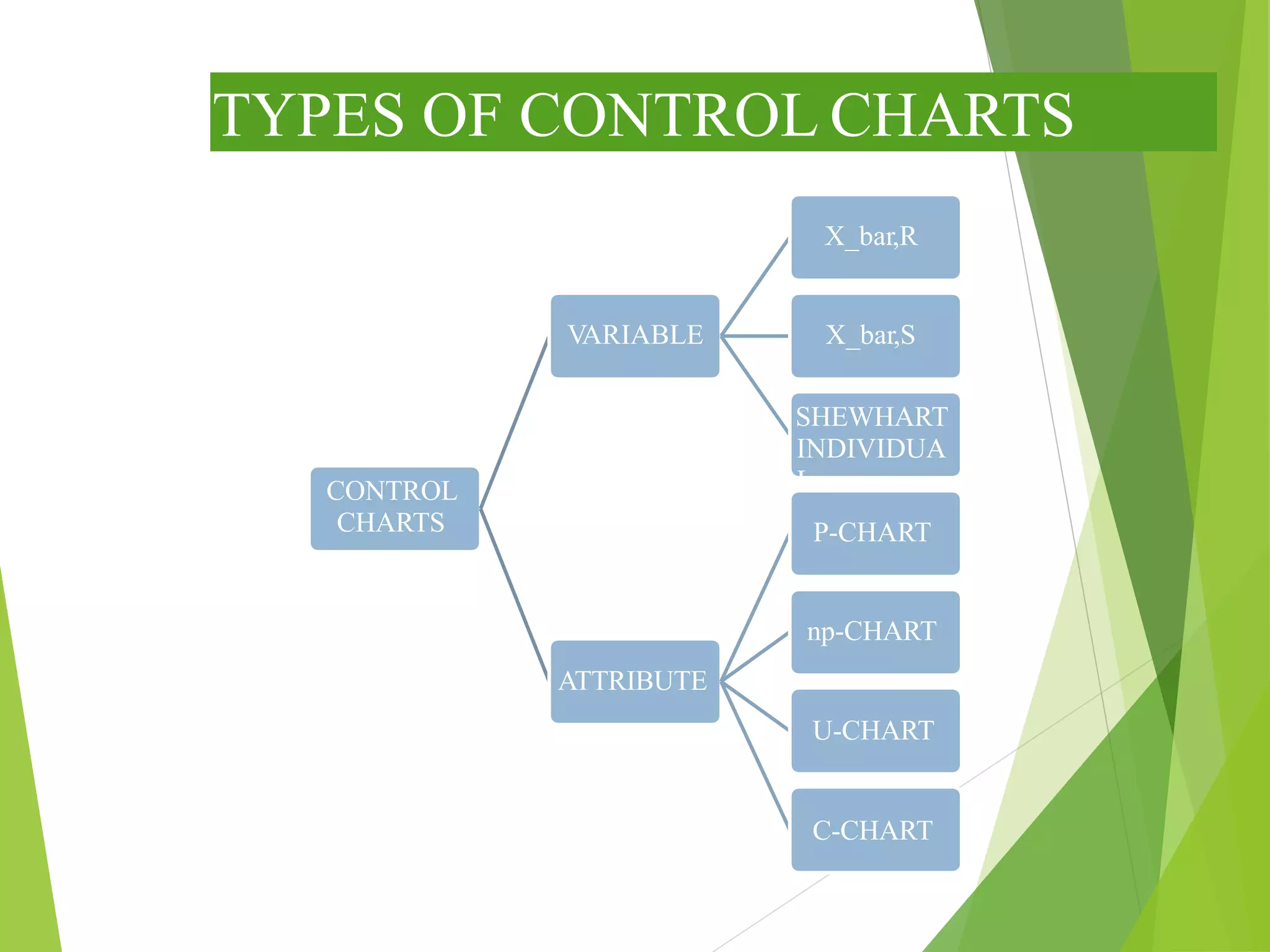

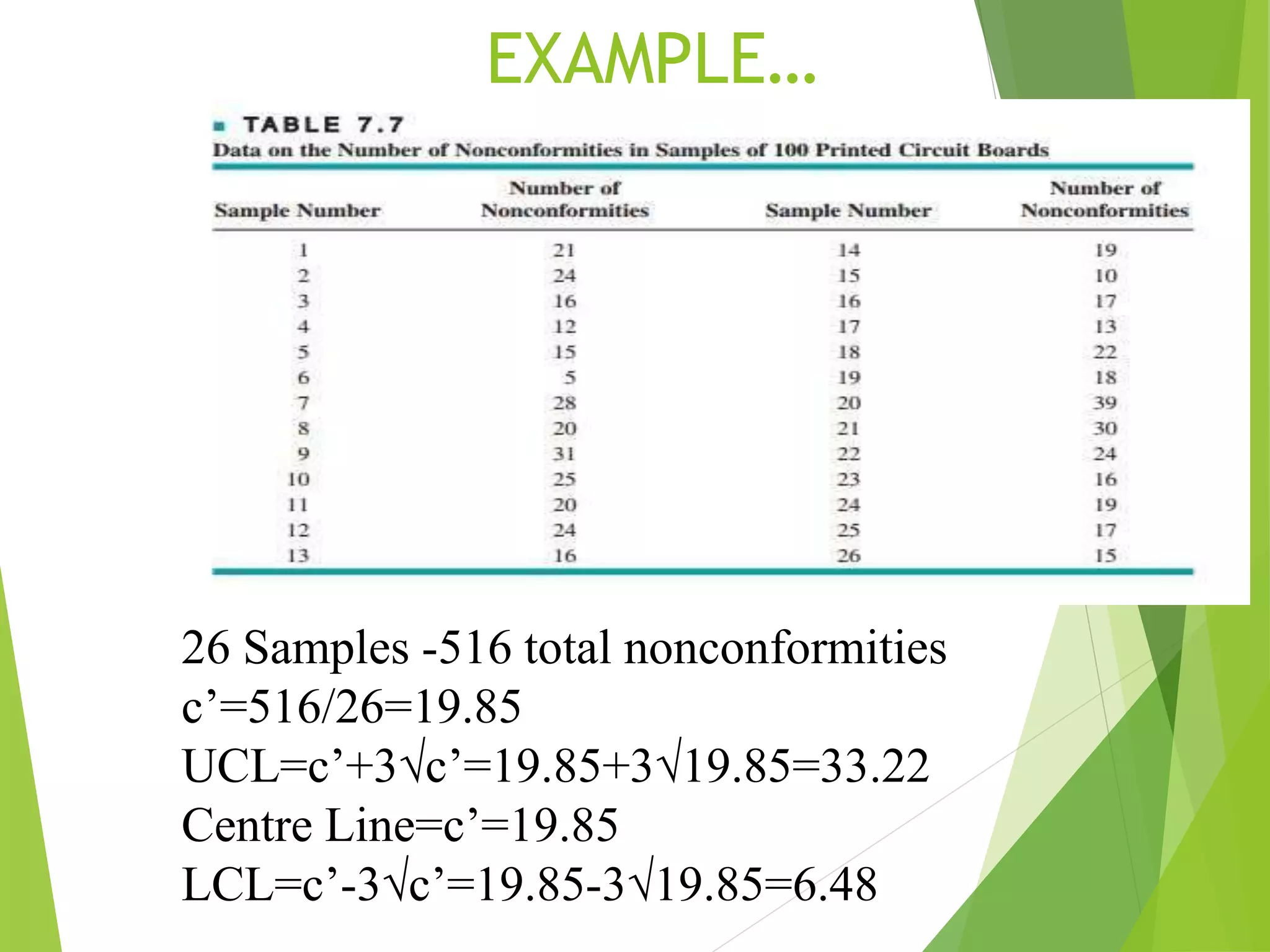

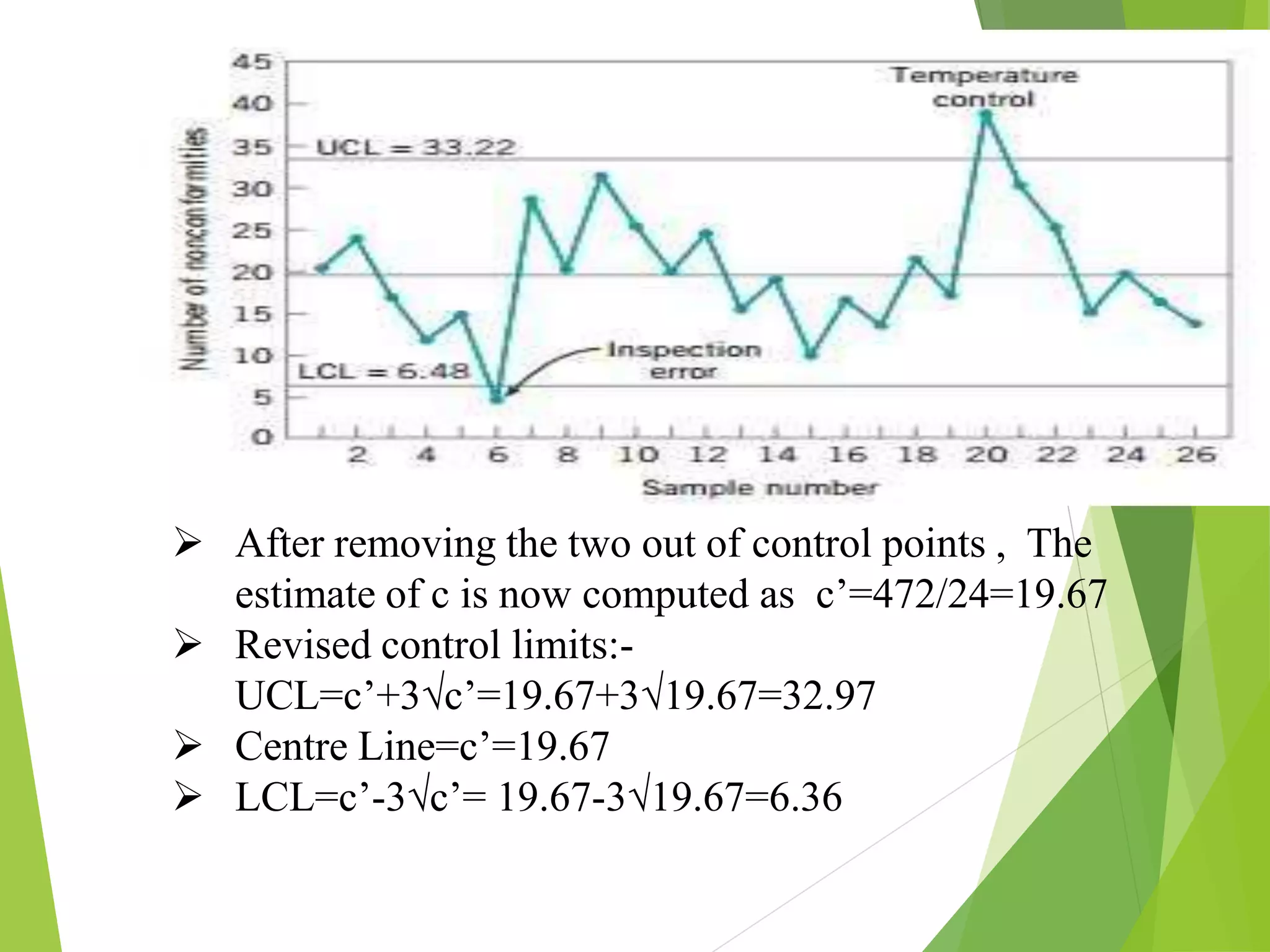

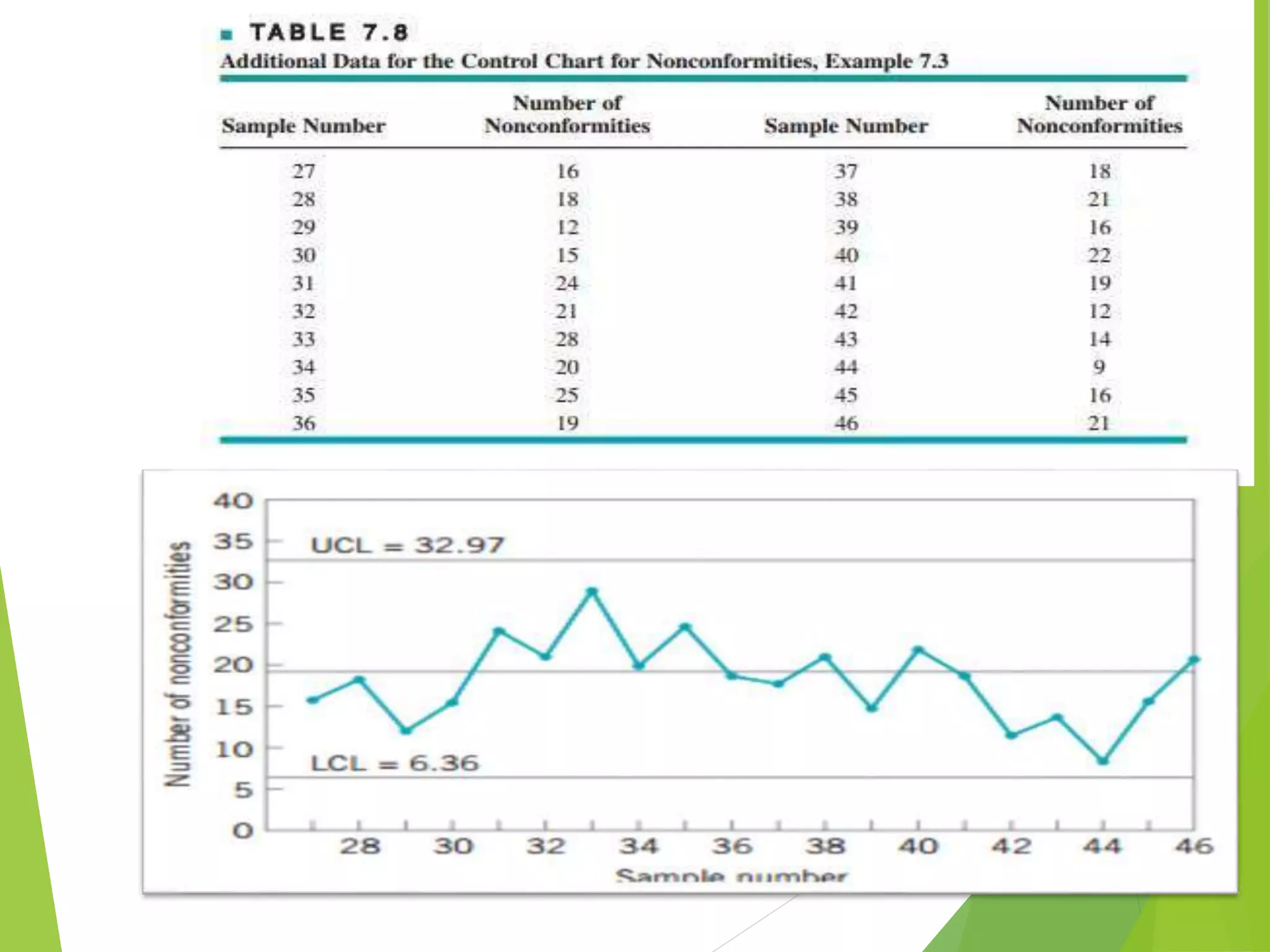

This document discusses C-charts, which are control charts used for nonconformities. C-charts can be used when a standard for nonconformities is given or not given. The chart contains an upper control limit, center line, and lower control limit. C-charts follow a Poisson distribution and are useful for healthcare process improvement and quality control. Examples are provided to demonstrate how to calculate control limits for a C-chart.