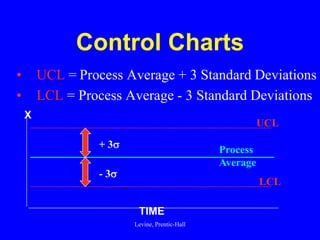

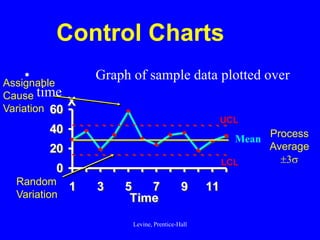

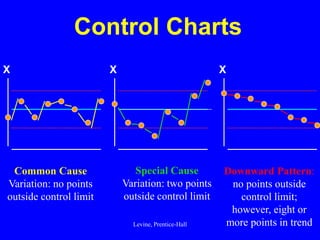

Control charts are statistical tools used for monitoring variation in product or service characteristics over time. They can evaluate past performance and improve processes using upper and lower control limits, and can be applied to both categorical and interval/ratio data through various chart types. Overall, control charts help identify common and special cause variations to ensure quality control.

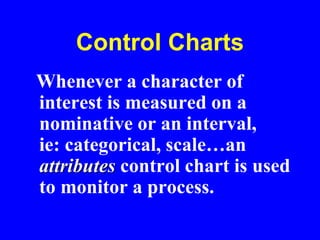

![Control Charts

Charts may

be used for

categorical

variables.

[i.e.: attributes]](https://image.slidesharecdn.com/controlcharts1-221020155117-fd1feec3/85/ControlCharts1-ppt-10-320.jpg)

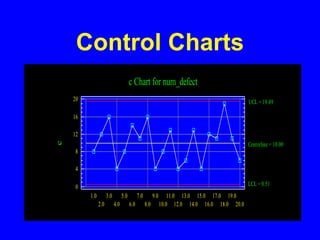

![Control Charts

• Attributes Control Charts

counts [c-chart]

proportion [p-charts]](https://image.slidesharecdn.com/controlcharts1-221020155117-fd1feec3/85/ControlCharts1-ppt-12-320.jpg)

![Control Charts

• Attributes Control Charts

when sample size are not constant

and/or are unknown

use counts charts

[c-charts]](https://image.slidesharecdn.com/controlcharts1-221020155117-fd1feec3/85/ControlCharts1-ppt-13-320.jpg)

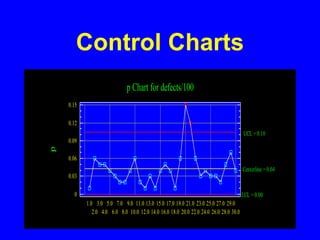

![Control Charts

• Attributes Control Charts

when sample size are constant

and are known

use proportion charts

[p-charts]](https://image.slidesharecdn.com/controlcharts1-221020155117-fd1feec3/85/ControlCharts1-ppt-15-320.jpg)

![Control Charts

Charts may

be used for

interval or

ratio data

[i.e.: variables ]](https://image.slidesharecdn.com/controlcharts1-221020155117-fd1feec3/85/ControlCharts1-ppt-17-320.jpg)

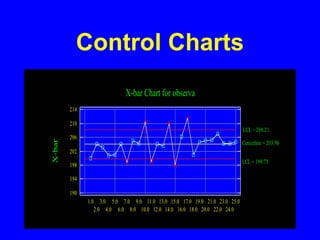

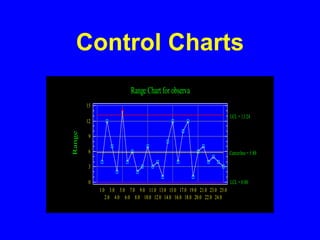

![Control Charts

• Variables Control Charts

Mean and Range charts

[x-bar & R charts]](https://image.slidesharecdn.com/controlcharts1-221020155117-fd1feec3/85/ControlCharts1-ppt-19-320.jpg)