The document discusses various topics related to electrical systems and illumination in buildings including:

- Basics of electricity including electrical charge, voltage, electric current, and electrical resistance.

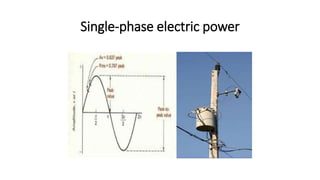

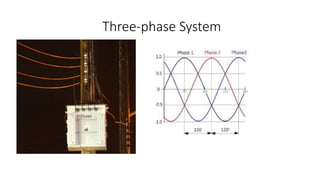

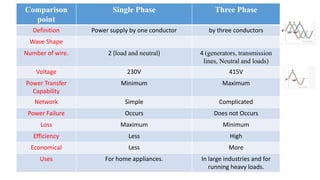

- Single phase and three phase electric power systems including their definitions, components, and comparisons.

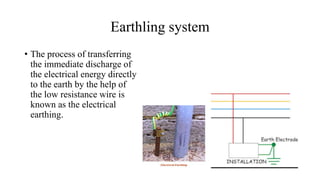

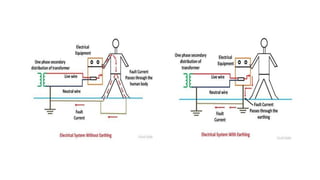

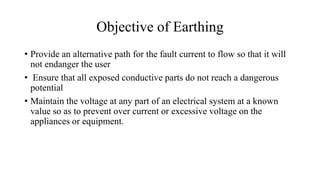

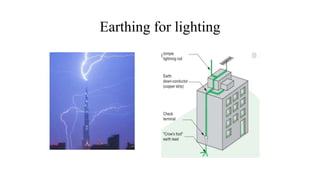

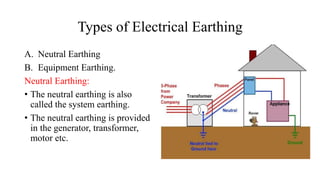

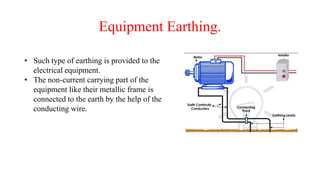

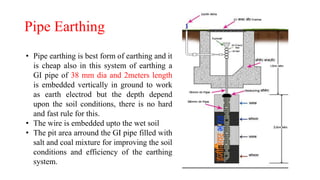

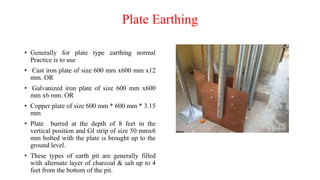

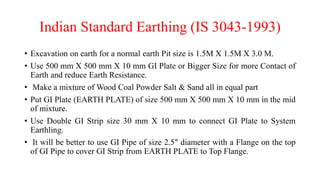

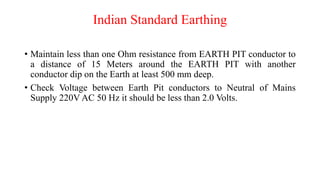

- Earthing (grounding) systems including their objectives, importance, types (neutral and equipment earthing), and construction according to Indian standards.

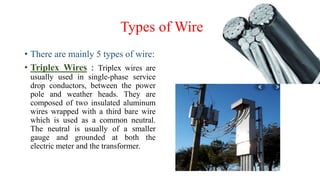

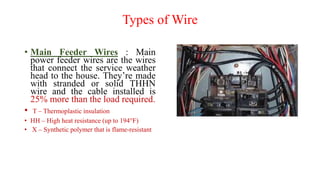

- Types of wires used in electrical systems including their considerations and common varieties like triplex, feeder, panel, non-metallic sheathed, cleat, wood casting, CTS, conduit, and metal/lead sheathed wires.