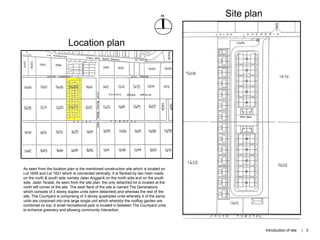

The document provides information about a low density housing development called Ramal Villa located in Kajang, Malaysia. It consists of 71 units including single detached homes and semi-detached homes. The development emphasizes modern design with flat roofs and simple facades. Each unit also has a rooftop garden. The site is well connected to major highways near LDP and Sungai Besi Highway, making it easily accessible. The document includes a location plan and site plan showing the layout of the different housing types.