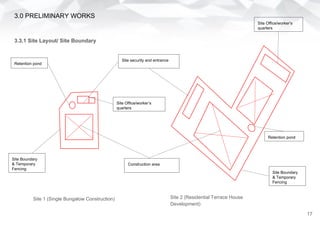

This document provides an overview of construction site safety and machinery used at a construction site in Bangi, Malaysia. It discusses personal protective equipment, site security measures, welfare facilities, and hazards/safety procedures for machinery, elevated work areas, scaffolding, and fall protection. Specific machinery covered include earth moving equipment like loaders, backhoes, excavators, and trucks. For each construction element, the associated hazards and solutions are outlined. The document aims to identify and properly manage safety aspects at the construction site.