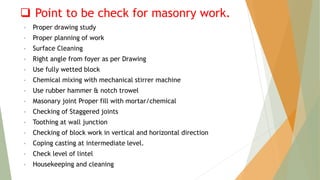

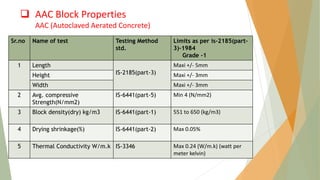

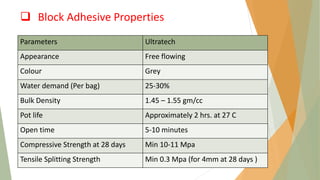

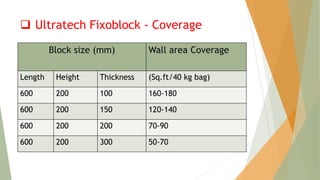

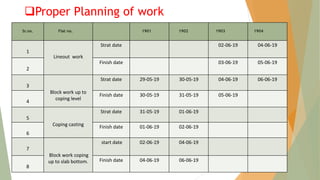

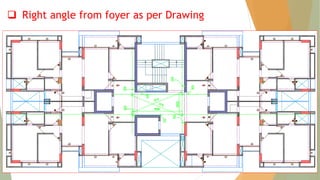

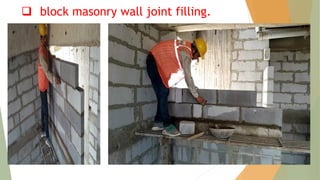

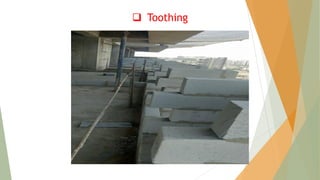

The document provides information on tools, materials, and procedures for AAC block masonry work. It lists tools needed like hammers, trowels, and measuring equipment. It outlines points to check like drawings, planning, cleaning, angles, wet blocks, and joint filling. Procedures covered include mixing mortar, using trowels and hammers, staggered joints, toothing, level checks, coping casting, and housekeeping. Product details are given for AAC blocks and adhesive properties like strength, density, shrinkage. Coverage rates per bag of adhesive are listed for different block sizes.