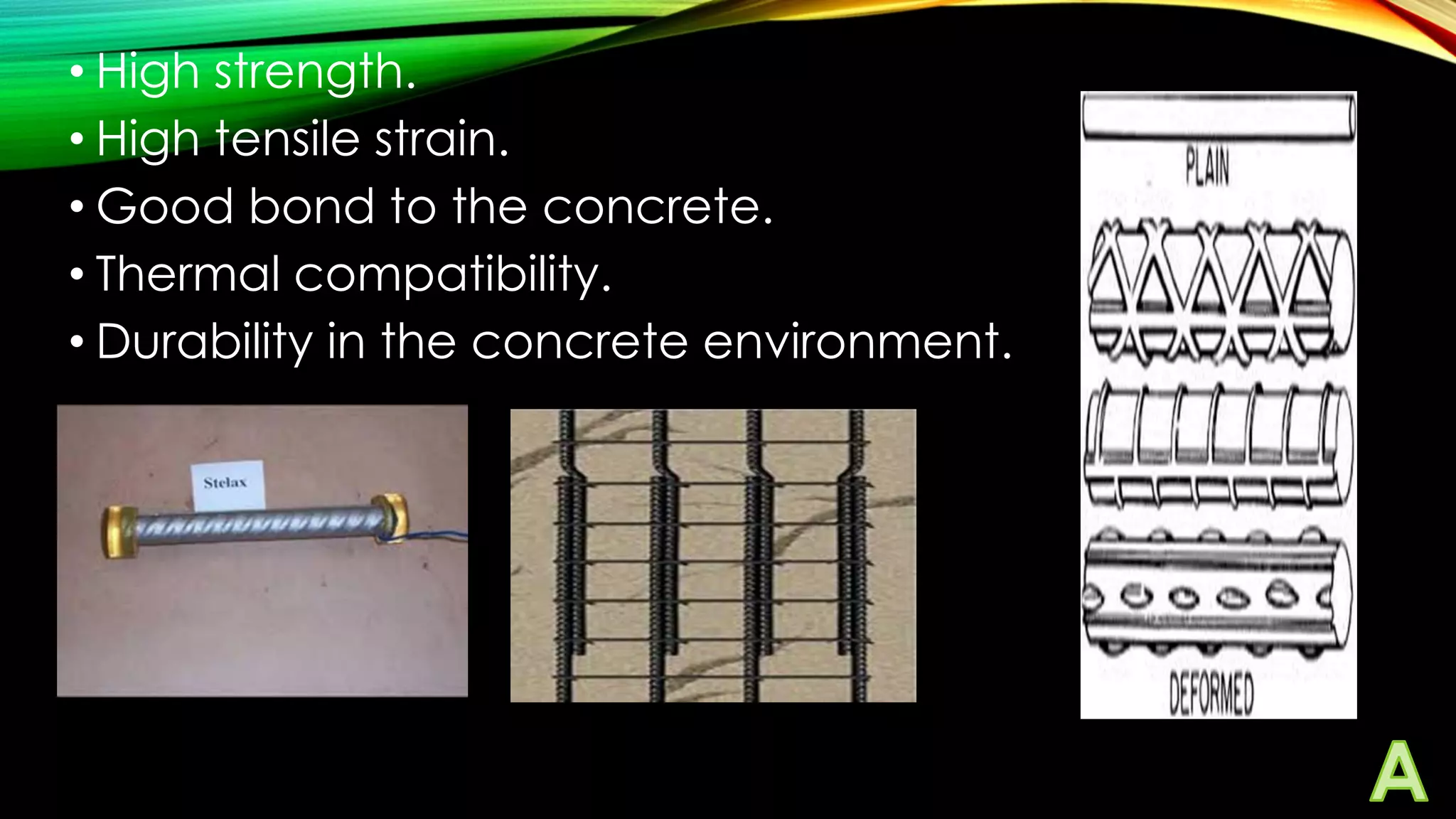

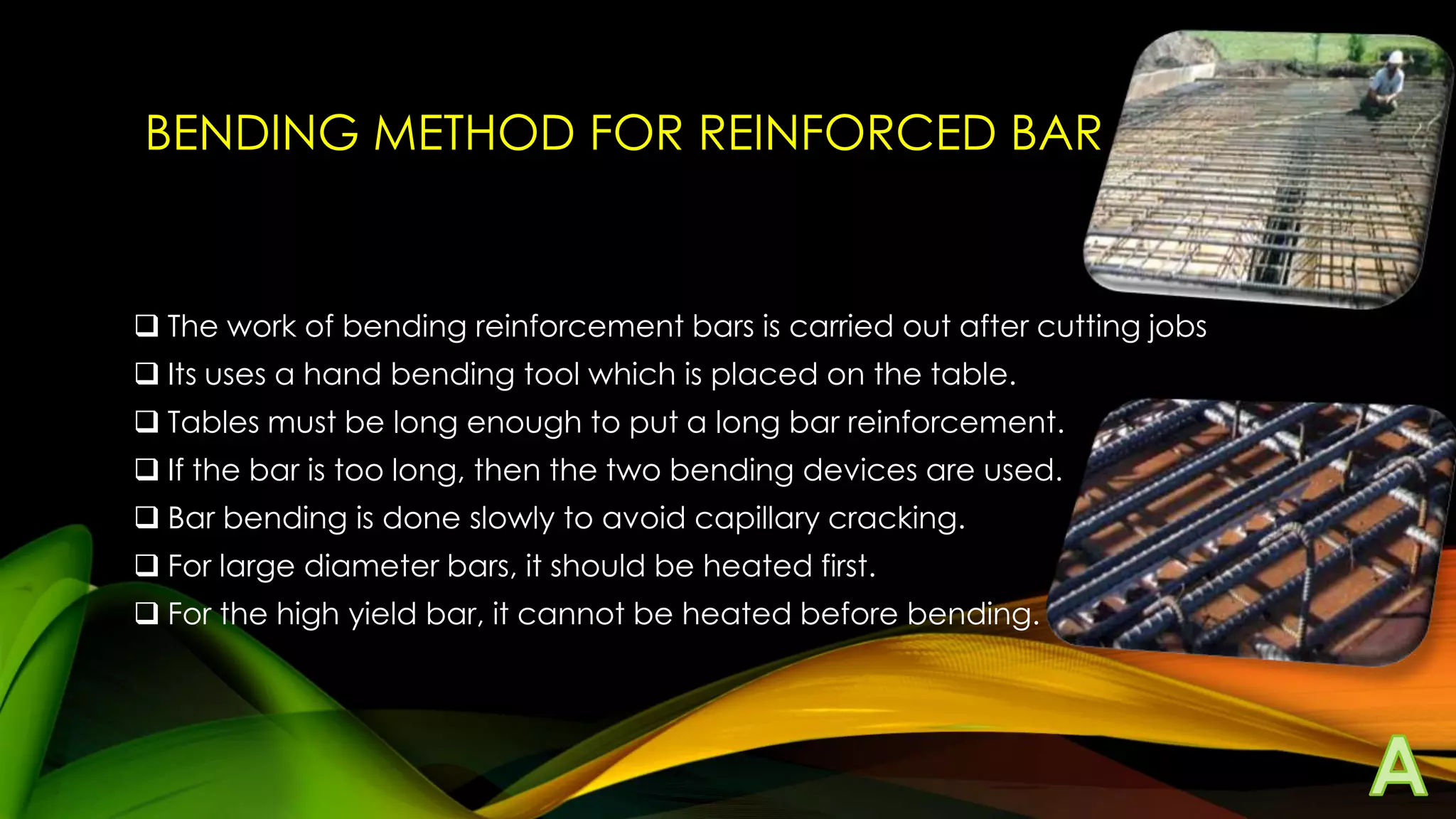

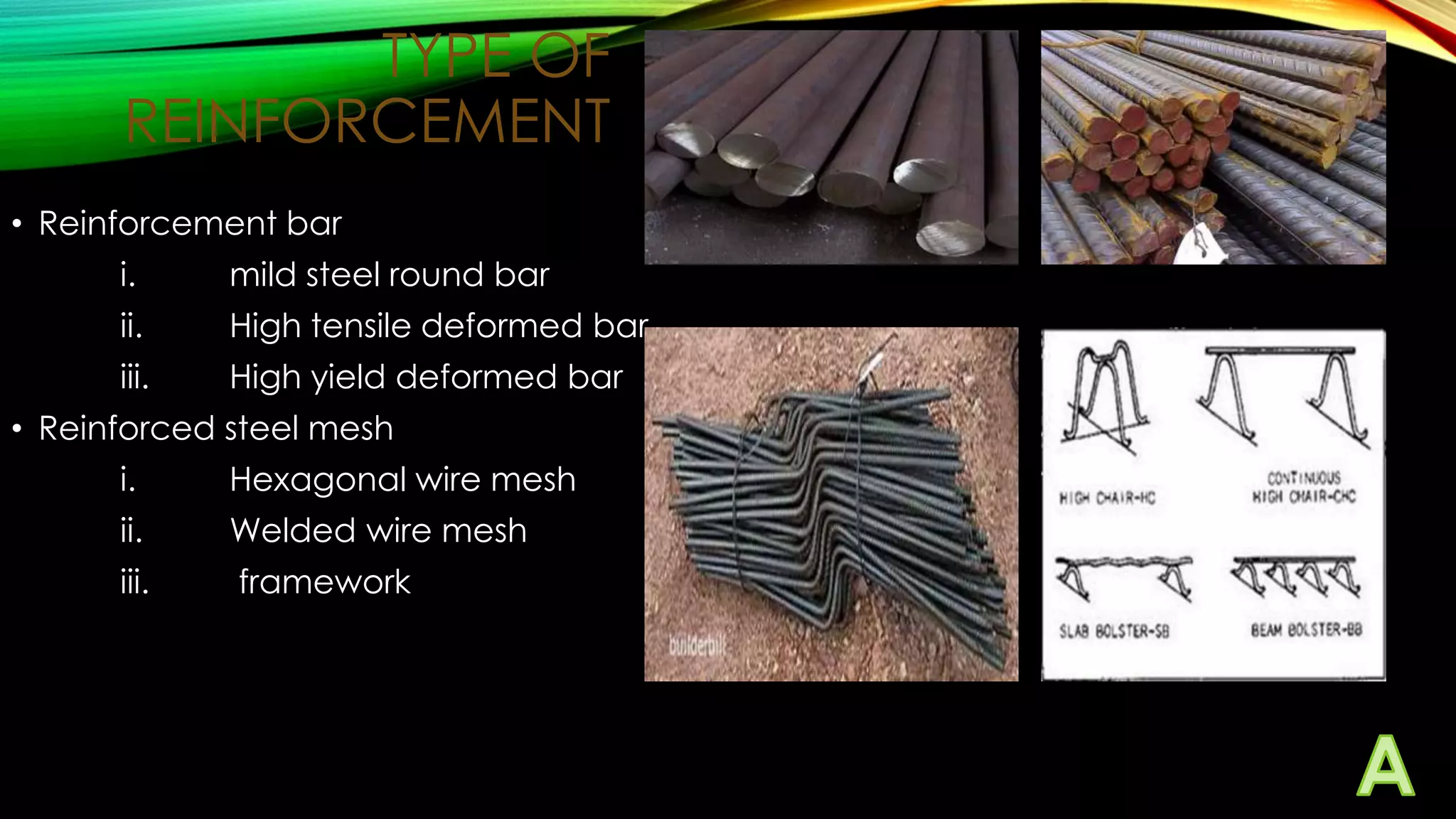

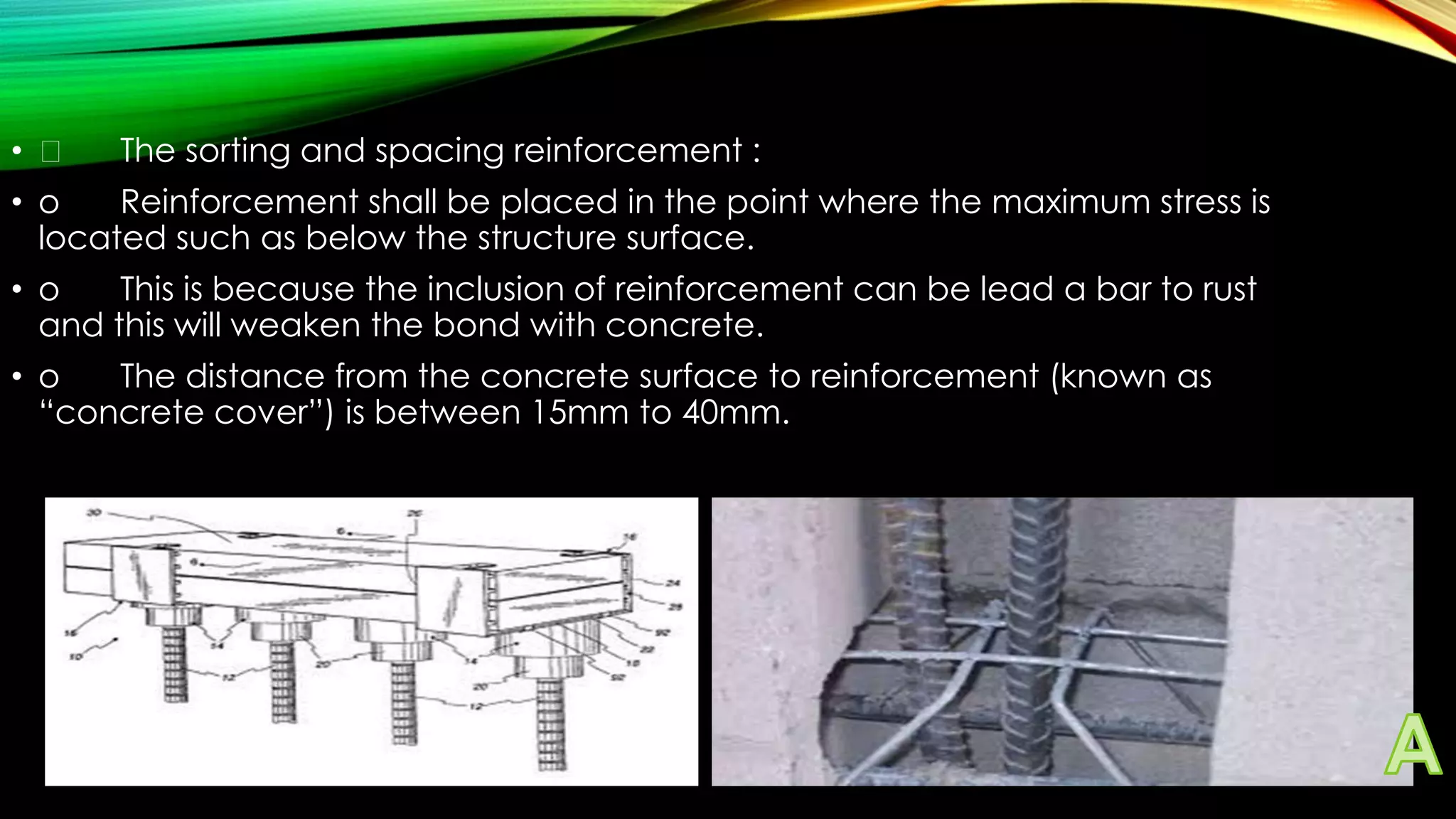

This document discusses reinforced concrete and its properties. It explains that concrete is weaker in tension than compression, while steel has high tensile strength and bonds well with concrete. When combined, they form reinforced concrete which is strong and durable. The steel carries tensile forces while the concrete resists compression. Proper placement of reinforcement during construction is important for bond. Methods of bending, tying, and installing rebar are also outlined.