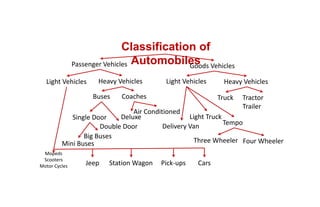

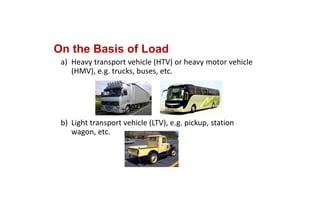

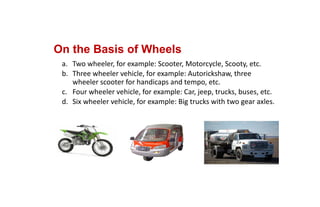

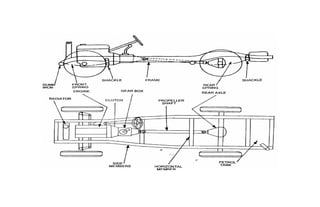

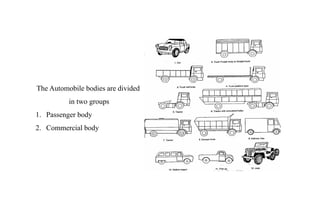

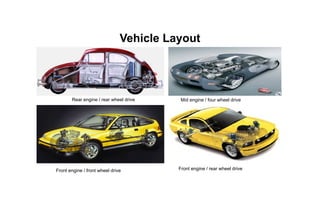

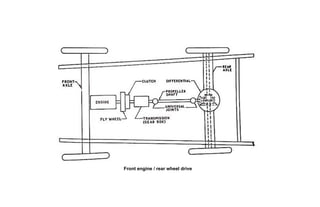

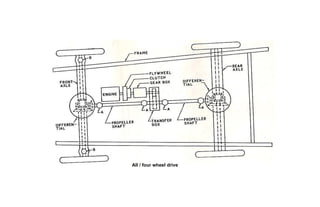

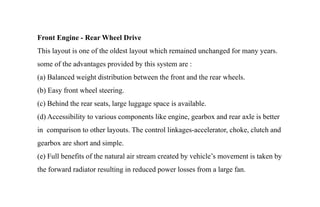

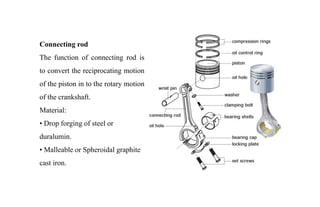

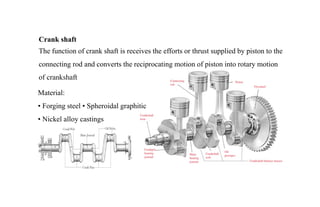

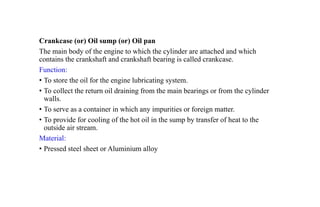

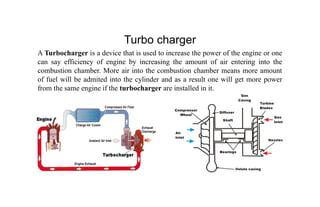

This document discusses the classification and layout of automobiles. It categorizes vehicles based on factors such as load, number of wheels, fuel used, body style, transmission, drive, suspension system, engine position, and chassis type. Common passenger vehicle layouts include front-engine/front-wheel drive, front-engine/rear-wheel drive, and all-wheel drive. Components like the engine, drivetrain, and suspension are described along with their functions and materials. Methods of forced induction like turbocharging and supercharging are also introduced.