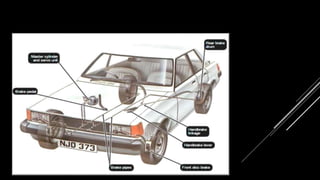

1) Modern cars use hydraulic braking systems with disc or drum brakes on all four wheels. Most cars have dual hydraulic circuits for redundancy.

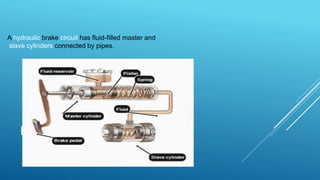

2) The hydraulic system uses a master cylinder activated by the brake pedal to push brake fluid through the lines, which activates slave cylinders at each wheel cylinder.

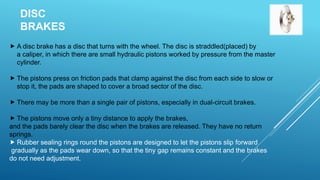

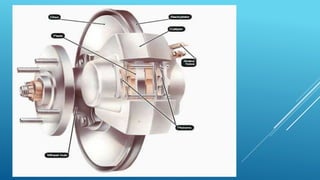

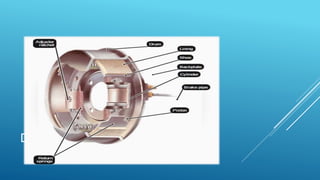

3) Disc brakes use calipers to squeeze brake pads against a rotor, while drum brakes use shoes pressed against the inner surface of a hollow drum by wheel cylinders.