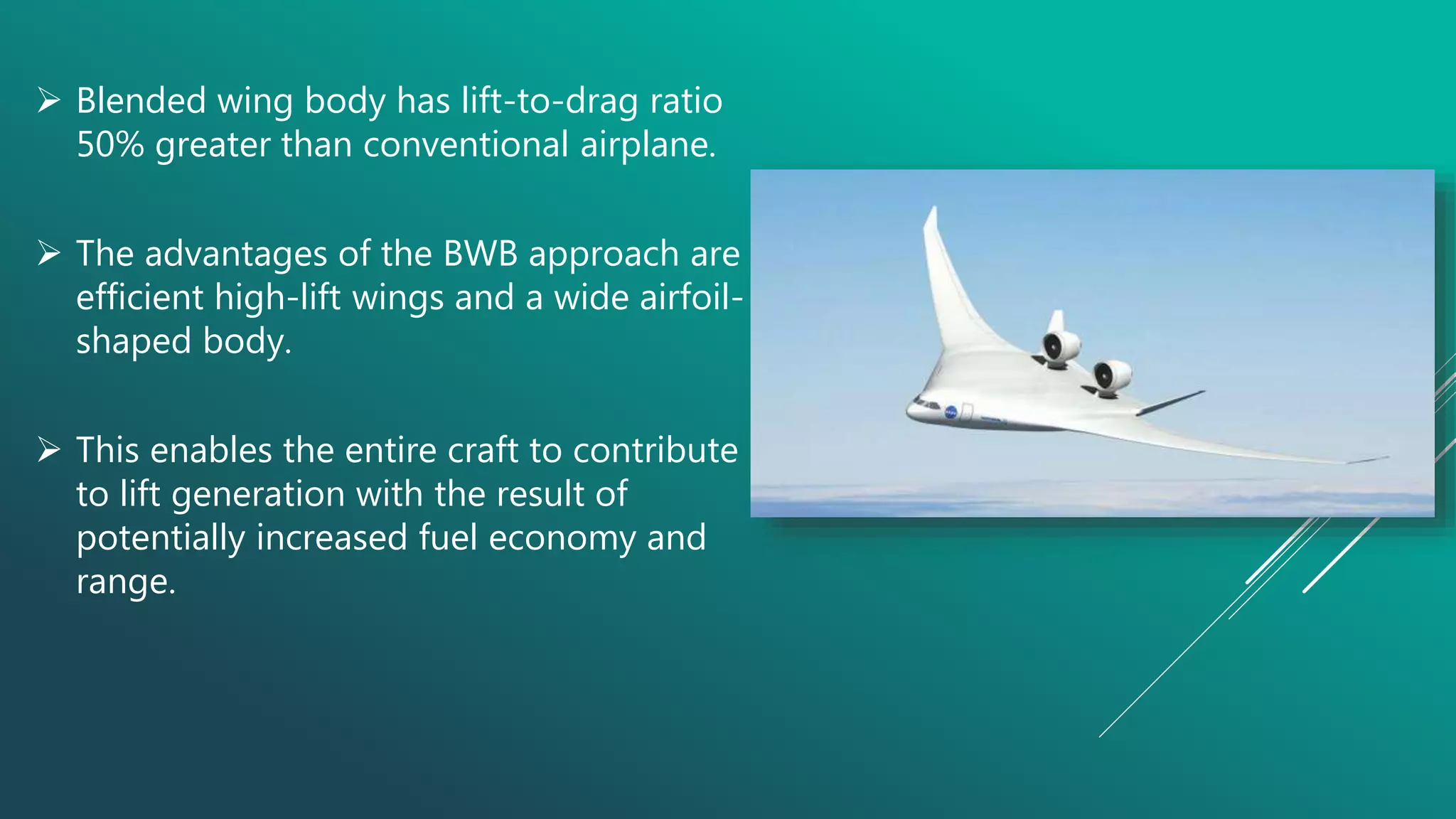

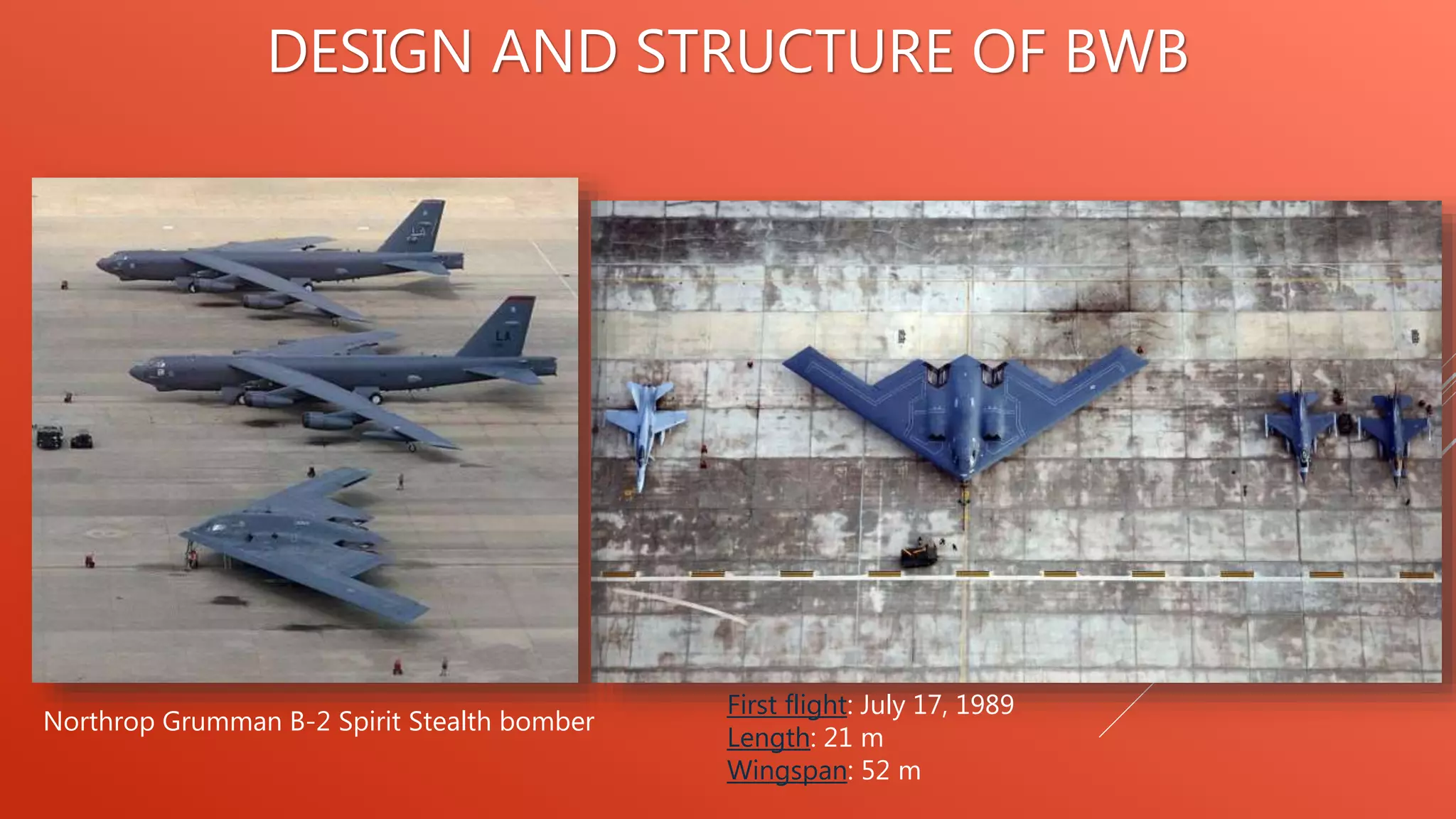

The document discusses the Blended Wing Body (BWB) aircraft, which integrates wings and fuselage to enhance lift and fuel efficiency, potentially accommodating up to 800 passengers. It outlines the historical context, design advantages, and disadvantages of BWB compared to conventional aircraft, emphasizing its aerodynamic benefits and challenges related to structural integrity and passenger safety. The future scope suggests BWB could address rising air traffic demands with innovative thrust mechanisms and reduced environmental impact.

![Northrop N1M “Jeep”, by Northrop Corporation, USA

The concept of Blended Wing

body was introduced almost

27 years ago.

The idea was to build a new type of

aircraft that would allow the aircraft

to carry more passengers.

[1]](https://image.slidesharecdn.com/blendedwingbody1-161122055539/75/Blended-Wing-Body-BWB-Future-Of-Aviation-5-2048.jpg)

![The wake of a Boeing 767

disrupts the top

of a cumulus cloud and clearly

shows the

counter-rotating trailing

vortices.[2]](https://image.slidesharecdn.com/blendedwingbody1-161122055539/75/Blended-Wing-Body-BWB-Future-Of-Aviation-14-2048.jpg)

![DESIGN AND STRUCTURE OF BWB

[3]

[4]

[5]](https://image.slidesharecdn.com/blendedwingbody1-161122055539/75/Blended-Wing-Body-BWB-Future-Of-Aviation-23-2048.jpg)

![VELA 2 baseline

concept[6]](https://image.slidesharecdn.com/blendedwingbody1-161122055539/75/Blended-Wing-Body-BWB-Future-Of-Aviation-24-2048.jpg)

![DESIGN AND STRUCTURE OF BWB

Cambridge MIT silent aircraft concept

(Source: The Cambridge-MIT Institute). [7]

The ACFA BWB configuration

The project called Active Flight Control for Flexible

Aircraft is the design of an innovative ultra efficient 450

passenger capacity BWB aircraft with highly swept back

center-body and 2 podded turbofan engines [8]](https://image.slidesharecdn.com/blendedwingbody1-161122055539/75/Blended-Wing-Body-BWB-Future-Of-Aviation-25-2048.jpg)

![DESIGN AND STRUCTURE OF BWB

CONCEPT OF WINDOWLESS

AIRCRAFT[9]

BWB CONCEPTUAL SEATING

ARRANGEMENT[10]

BOEING X48C PROTOTYPE (2011)[11]](https://image.slidesharecdn.com/blendedwingbody1-161122055539/75/Blended-Wing-Body-BWB-Future-Of-Aviation-26-2048.jpg)

![CONVENTIONAL AEROPLANES VS BWB

Transformation of a 650m2

ball into a conventional and

BWB aircraft [12]](https://image.slidesharecdn.com/blendedwingbody1-161122055539/75/Blended-Wing-Body-BWB-Future-Of-Aviation-27-2048.jpg)

![PERFORMANCE COMPARISON

BETWEEN A CONVENTIONAL

AND BWB CONFIGURATION[14]

[13]](https://image.slidesharecdn.com/blendedwingbody1-161122055539/75/Blended-Wing-Body-BWB-Future-Of-Aviation-28-2048.jpg)

![LIFT Vs WEIGHT

DISTRIBUTION

[15]

[16]

[17]](https://image.slidesharecdn.com/blendedwingbody1-161122055539/75/Blended-Wing-Body-BWB-Future-Of-Aviation-29-2048.jpg)

![NO WINDOWS!!!

Each seat will have a multifunctional

LCD screen on the seat in front of them. A

selector will allow the passenger to select from a

number of views, including looking to the rear

and straight down.

It can be used as a cargo plane as it has large

space and there is no problem of internal

pressurization.

[18]](https://image.slidesharecdn.com/blendedwingbody1-161122055539/75/Blended-Wing-Body-BWB-Future-Of-Aviation-30-2048.jpg)

![ADVANTAGES AND DISADVANTAGES OF BWB

ADVANTAGES :-

Aerodynamics: The aerodynamic benefits of the

BWB are derived from the integration of its

‘fuselage’ and wings to obtain ‘low wetted

surface area to volume ratio’ and reduced

interference drag.

This lowers total drag and provides higher L/D

ratio compared to conventional configuration

DOC- direct operating costs includes

Fuel

Landing fees

Maintenance

Annual inspection

[19]](https://image.slidesharecdn.com/blendedwingbody1-161122055539/75/Blended-Wing-Body-BWB-Future-Of-Aviation-31-2048.jpg)

![ADVANTAGES AND DISADVANTAGES OF BWB

DISADVANTAGES :-

High bending stresses resulting from

the effect of pressure on the box-like

shape of the BWB

High bending stress associated

with a non-cylindrical pressure

vessel.

typical aircrafts have a cylindrical shape which requires less strength and is

easier to pressurize as opposed to the interior shape of a BWB.

[20]](https://image.slidesharecdn.com/blendedwingbody1-161122055539/75/Blended-Wing-Body-BWB-Future-Of-Aviation-33-2048.jpg)