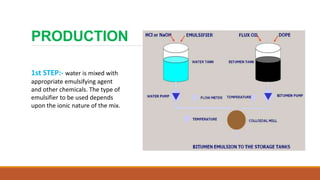

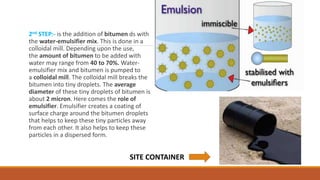

This document discusses bitumen emulsion, which is a mixture of bitumen, water, and an emulsifying agent. It defines bitumen emulsion and explains how the emulsifying agent allows bitumen to be suspended in water. The document then classifies emulsions based on surface charge and setting time. It describes the production process and lists applications such as road construction and soil stabilization. Factors affecting the setting time are outlined, and advantages like usability in wet conditions and less environmental impact are presented alongside limitations like variable curing times.