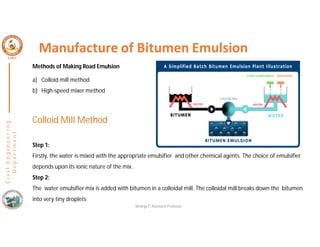

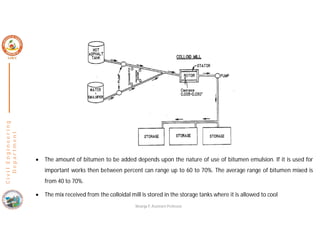

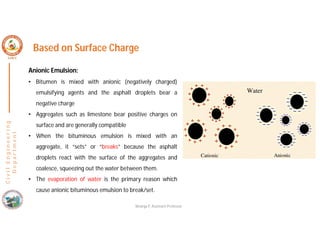

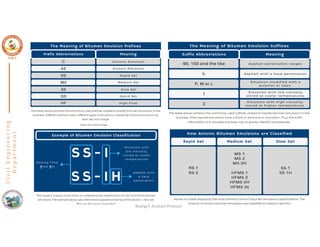

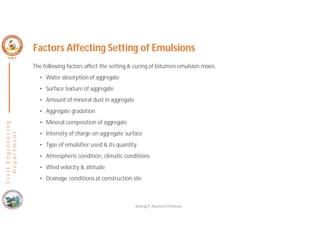

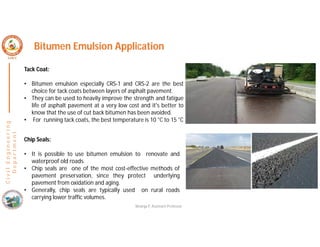

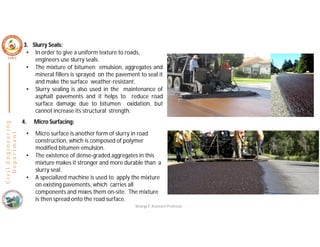

This document discusses bituminous emulsions and cutbacks. It describes the components, production methods, classification, properties, applications and testing of bitumen emulsions. The key production methods covered are the colloid mill method and high-speed mixer method. Bitumen emulsions are classified based on their surface charge as anionic or cationic, and also based on their setting time as rapid, medium or slow setting. Common applications include tack coats, chip seals, slurry seals and microsurfacing. Factors affecting the setting of emulsions and properties tested are also outlined.