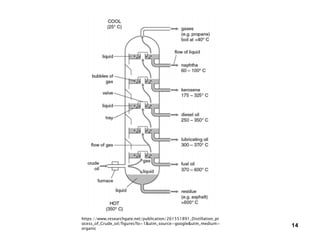

This document provides an overview of materials used for road construction including soils, aggregates, and binders. It discusses the necessary testing of these materials to determine quality, suitability, and prevent construction faults. Specific materials are described in detail such as soils, aggregates like sand and gravel, and binders like cement and different types and grades of bitumen. Refining and manufacturing processes for bitumen and asphalt are outlined. Important tests for materials are highlighted.