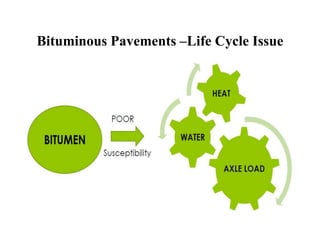

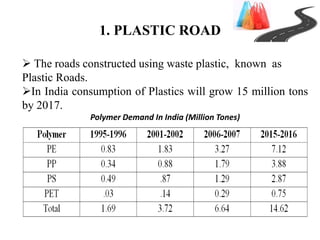

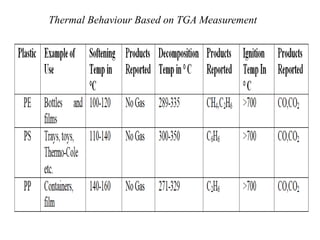

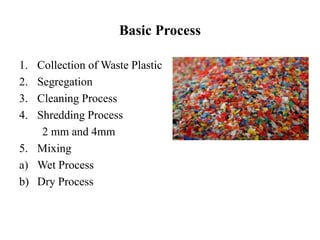

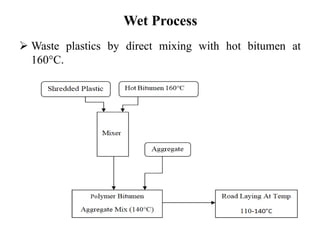

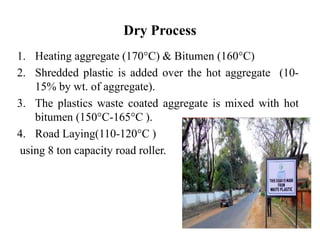

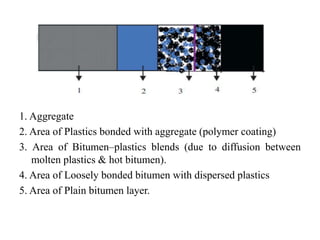

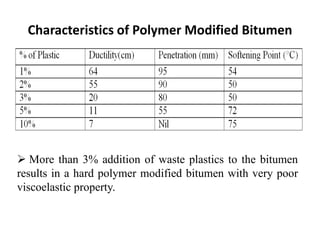

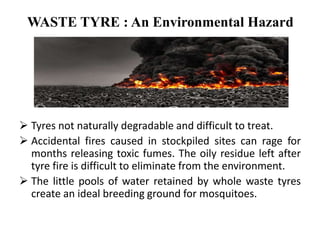

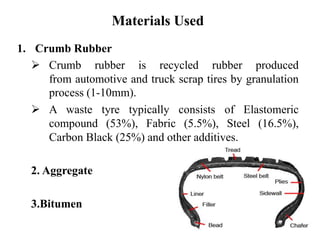

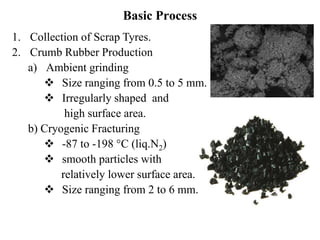

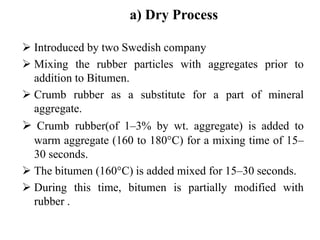

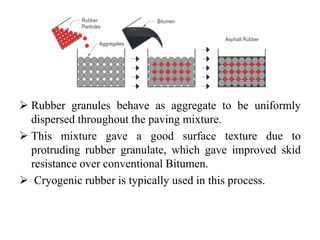

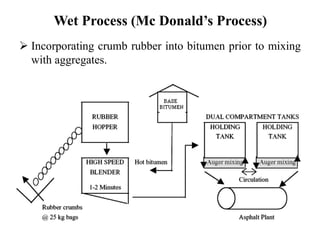

The document discusses the use of polymer modified bitumen for road construction, highlighting methods such as plastic and rubberized roads. It details the advantages and processes of modifying bitumen with waste plastics and crumb rubber, aiming to enhance road durability and reduce environmental pollution. Additionally, the document addresses the challenges and considerations in the application of these materials in the construction industry.