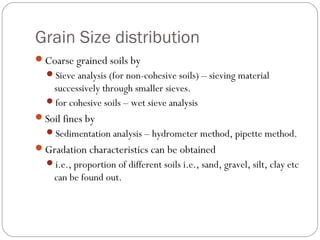

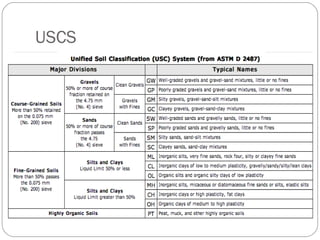

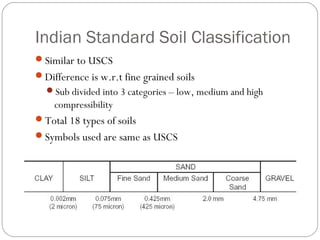

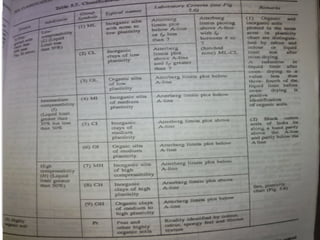

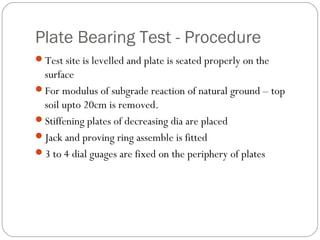

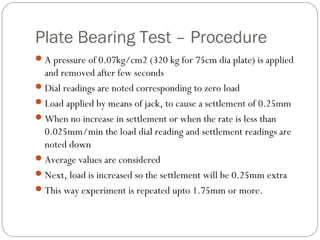

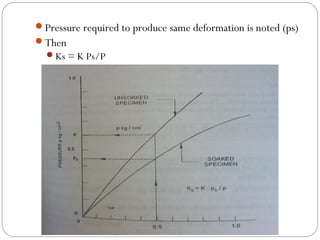

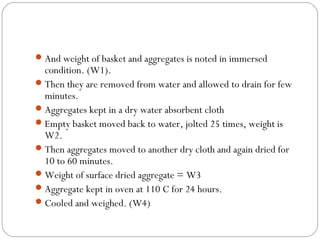

The document discusses the essential aspects of pavement materials, including the requirements for soil properties, types of aggregates, and various tests for evaluating their characteristics. It emphasizes the importance of soil stability and compaction in pavement construction to prevent failures like cracking and rutting, and outlines various classification systems for soils. Additionally, it details testing methods such as shear, bearing, and California Bearing Ratio tests to assess the quality and suitability of materials used in pavements.