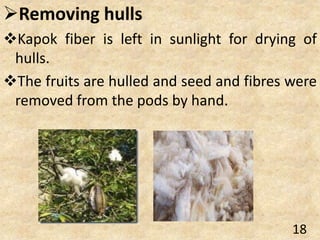

The document discusses kapok, a fibrous substance derived from the ceiba tree, comparing it with cotton and detailing its properties, processing, and end uses. Kapok is primarily used for stuffing in pillows and mattresses but has seen a decline in market demand due to synthetic alternatives. Despite its advantages, such as being lightweight and biodegradable, kapok is fragile and has limitations in weaving and spinning.