kenaf CE presentation.pdf

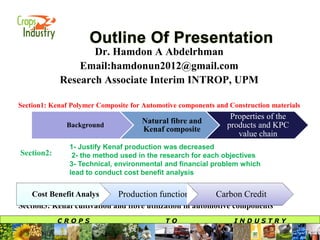

- 1. C R O P S T O I N D U S T R Y Dr. Hamdon A Abdelrhman Email:hamdonun2012@gmail.com Research Associate Interim INTROP, UPM Section1: Kenaf Polymer Composite for Automotive components and Construction materials Section2: Section3: Kenaf cultivation and fibre utilization in automotive components Background Natural fibre and Kenaf composite Properties of the products and KPC value chain Cost Benefit Analysis Production function Carbon Credit 1- Justify Kenaf production was decreased 2- the method used in the research for each objectives 3- Technical, environmental and financial problem which lead to conduct cost benefit analysis

- 2. C R O P S T O I N D U S T R Y Kenaf (Hibiscus cannabinus) • Asia • Africa • America • Europe Diameter of elementary fibre: 13 – 20 [µm]:

- 3. C R O P S T O I N D U S T R Y Fibre Kenaf Morphology & anatomy 3 Seed Stem (morphology and anatomy) Leaf Root system Inflorescence, Flower Fruits

- 4. C R O P S T O I N D U S T R Y Environmental conditions needed for fibre kenaf growing • temperature, •water (precipitation, soil, air humidity) •soil •forecrop - (position in the Rotation Cycle) Fibre flax Linseed (oil flax) Growing conditions of bast plants – input requirements

- 5. C R O P S T O I N D U S T R Y 5 BBCH 00 10 11 12 14 16 36 55 65 75 83 85 TRIPS Kenaf seedling emerge HARVESTING WEEDS DISEASES DISEASES Post emergent cultivation – plant protection

- 6. C R O P S T O I N D U S T R Y Kenaf fibre products Kenaf (Hibiscus cannabinus L.) has been recognized to be used for manufacturing of pulp production; structural materials and lightweight vehicle parts for its high yielding of fibre and impressive characteristic. Kenaf fibre has a diverse applications such as fabrics and yarns, ropes, twines, nets (Lips & van Dam, 2013).

- 7. C R O P S T O I N D U S T R Y Plastic materials which caused environmental problems Plastic polymer Characters and uses Polyethylene (PE) Tensile strength and modulus have a general correlation high density, high MW = high strength, high modulus. The usage 1. used in bearings, gears, artificial joints, films 2. used in car covers Polypropylene (PP) -Usage ranges from bumpers to carpets - used in interior, pillar and exterior trim, door panels. Polystyrene (PS) Liquid hydrocarbon that is commercially manufactured from petroleum. - High impact and explosion resistance. Polyvinyl chloride (PVCs) used as vinyl siding, window profiles, pipes - Addition of plasticizers increases flexibility for use in upholstery, tubing, and flooring. - linked to numerous health risks including cancer and -reproductive disorders due to dioxin release -The utilizing of plastic material makes the reprocessing reasonably problematic, and unacceptable for the high costs, the practical difficulties and the ecofriendly impact of final product (Miao & Finn, 2008). -The problematic of rising worldwide prices of petroleum and oil have caused the attention in renewable resources, also the pressure of the law for greener technologies, as well as customers’ request for more environmental-friendly punter goods is compelling products suppliers and industrialists to consider the environmental impact of their products at all stages of their life cycle, including processing, recycling and even their disposal (Bismarck. Etal,.2006)

- 8. C R O P S T O I N D U S T R Y General description of the material used in NFs polymer composite for automotive components and building material - Due to their best characteristic such as reduced weight and lower manufacturing costs composite are the topic of wide range of researchers concern, precisely in the construction and building industry. Currently, not only builders but also many homeowners are interested in using composite for components such as decks, fencing, and so on (FAO, 2012). - (Thamae & Baillie, 2008) did an environmental research to compare Natural Fibre Composite car door panels (manufactured from wood fiber and poly-propylene) with conventional glass fiber reinforced panels; their results indicated that, the part which made of a Natural Fibre Composite material reduced the environmental impacts of the panels.

- 9. C R O P S T O I N D U S T R Y Comparison of advantages between natural and glass fibers (Sreenivasan, Sulaiman, Baharudin, Ariffin, & Abdan, 2013) Properties Natural fibre E-glass Density Low Twice that of NF Renewability yes No Recyclability yes NO Energy consumption low high Distribution Wide Wide Co2 Neutral Yes No Abrasion to machines No Yes Installation health risk No Yes Disposal Biodegradable Not biodegradable

- 10. C R O P S T O I N D U S T R Y Cont. The manufactured properties of the natural fibre composite light and heavier weight depend on the fibre and the matrix used addition as well as the treatments applied to the natural fibre, these treatment will improve the natural fibre composite by enhance the adhesion between the natural fibre and the matrix. -There two groups of composites based on type of fibre added: short-fibre and long fibre composite(Ticoalu, Aravinthan, & Cardona, 2010) and (Shah, 2013). -The common usage of short fibre in saleable of composites is sawdust; these are characteristically referred to as Wood Plastic Composites (WPCs). The usage of long fibers of NFCs can outcome with brilliant mechanical properties, mostly when fibers are coated at an angle or woven (Hull & Clyne, 1996). These sorts of fibres more valued and expensive than other fibre owing to their appropriateness for further uses (Baillie et al., 2011).

- 11. C R O P S T O I N D U S T R Y Cont. NFC • Natural fiber composites appeared to be as replacements to glass-reinforced composites in several industrial usages. 1- for example hemp fiber-epoxy, flax fiber-polypropylene (PP), and china reed fiber-PP are mostly used by the customers in automotive applications due to their lower price and lower density. 2- Glass fibers used for composites have density of 2.6 g/cm3 and cost between $1.30 and $2.00/kg. In comparison, flax fibers have a density of 1.5 g/cm3 and cost between $0.22 and $1.10/kg (Foulk, Akin, & Dodd, 2000)

- 12. C R O P S T O I N D U S T R Y (Joshi, Drzal, Mohanty, & Arora, 2004) concluded that, natural fiber composites environmentally seen to be better than the glass fiber composites because of the subsequent advantages: (1) when produced natural fiber has lower impact in environment when compared to glass fiber production; (2) natural fiber composites contains higher fiber, these decreases more littering base polymer contents; (3) the light-weight of natural fiber composites mend fuel efficiency and lessen emissions in the use phase of the component, particularly in automobile applications; and (4) end of life burning of natural fibers results in a healthier energy and carbon esteems

- 13. C R O P S T O I N D U S T R Y The importance of Kenaf as bast fibre plant Kenaf grows speedily, attainment to 4-5m in height and 25-35 mm in diameter in a 4-5 month growing season. Kenaf has high biomass output, a broad growth area, strong adaptability to environment (Li and Mai, 2006). Kenaf has a very high carbon dioxide amalgamation rate (1 ton Kenaf biomass absorbs 1.5 tons of atmospheric CO2), and is a good plant for alleviating the global warming (IJSG, 2012). Kenaf entails fewer water to grow than other fibrous plants such as ( Jute, hemp, flax, ramie, etc.), can adapt to a wider variety of soils and climates (Alexopoulou, Papatheohari, Christou, & Monti, 2013).

- 14. C R O P S T O I N D U S T R Y Chemical composition of Kenaf fibers The chemical constituents: cellulose, hemicelluloses, and lignin. Also, there are three principal component, kenaf consist about 2% of negligible constituents: fats and waxes (0.4-0.8%), inorganic matter (0.6-1.2%), nitrogenous matter (0.8-1.5%), and traces of pigments (Monti & Alexopoulou, 2013).

- 15. C R O P S T O I N D U S T R Y The properties of kenaf and other bast fibres Mechanical properties of different bast fibrous crop (Monti & Alexopoulou, 2013) Fibre crop Tensile strength (MPa) Young’s modulus (GPa) Elongation at break (%) kenaf 580– 750 - 1.3–2.3 Jute 393–773 26.5 1.5–1.8 Ramie 400–938 61.4–128 3.6–3.8 Hemp 690 - 1.6–2.2

- 16. C R O P S T O I N D U S T R Y Cont. properties -The properties of individual fibres differ due to their shapes, sizes, and orientations, and the thickness of the cell walls (Salman et al., 2015) . -Some important physical elements must be known about each cultivation of variety before it utilized into composite. The fibre length as well as diameter are very crucial elements to determine the strength of natural fibre (Bavan & Kumar, 2010). The fiber’s strength is an important factor when choosing a fibre that is specific for a certain usage.

- 17. C R O P S T O I N D U S T R Y Properties of kenaf yarns and plain weave kenaf fabrication (Salman et al., 2015). Properties Kenaf yarn Yarn fineness (Tex) 942 Yarn type 1 ply spun Twist direction Z-twist Fibre diameter (mm) 1 ± 0.1 Yarn breaking load (N) 79 Average breaking strength (MPa) 100.64 Average maximum strain (%) 17.3 Characterization Woven kenaf Thickness (mm) 2 ± 0.2 Weight (g/m2) 890 Density (g/cm3) 1.2 Warp density (warp/inch) 12 Weft density (weft/inch) 12 Wavelength, ƛ (mm) 4.2 Interyarn fabric porosity (𝜀) 0.274 Moisture content (%) 8.353 Water uptake (%) 148.86

- 18. C R O P S T O I N D U S T R Y The usage of natural fibres for vehicle parts in Germany (Monti & Alexopoulou, 2013)

- 19. C R O P S T O I N D U S T R Y In Brazil the average consumption of natural fibre reinforcement in the automotive industry amounts to (Leao, 2010) • Front door liners [1.2-1.8 kg] • Rear door liners [0.8-1.5 kg] • Boot liners [1.5-2.5 kg] • Parcel shelves [2 kg] • Seat backs [1.6-2.0 kg] • Sunroof interior shields [0.4 kg] • Headrests [2.5 kg]

- 20. C R O P S T O I N D U S T R Y Non-deseeded raw straw Biomass for bio-fuel Deseeded raw straw Seeds Dew-retted straw Shives & dust Technical fiber Short fiber scutched tows Short fiber matted tows Special carded yarn Weaving Carded yarn Bedlinen fabrics Decorative fabrics Cottonized fiber Special carded yarn Weaving carded yarn Ropes Long scutched fiber Special carded yarn Cleaning material Combing waste fiber Carded yarn Bedding material Insulating matarial Paper production Felts Threads Technical and decorative fabrics Nets and others Ropes Long combed fiber Special combed yarn Spinning waste material Weaving carded yarn Paper production Bedding material Nonwovens Nets and other Sowing seed 20

- 21. C R O P S T O I N D U S T R Y Kenaf pultrusion

- 22. C R O P S T O I N D U S T R Y Why selecting Natural fibres for Industrial Applications (FAO, 2012). 1- Low density: which may lead to a weight reduction of 10 to 30%; 2- Acceptable mechanical properties, good acoustic properties; 3- Favorable processing properties, for instance little wear on tools, etc.; 4- Options for new production technologies and materials; 5- Favorable accident performance, high stability, less splintering; 6- Favorable Eco balance for part production; 7- Favorable Eco balance during vehicle operation, due to weight savings; 8- Occupational health benefits (compared to glass fibres) during production; 9- No off-gassing of toxic compounds (in contrast to phenol resin-bonded wood and recycled cotton fibre parts); 10- Reduced fogging behavior; 11- Price advantages regarding both fibres and applied technologies.

- 23. C R O P S T O I N D U S T R Y Section2 1- Justify Kenaf production was decreased 2- Technical, environmental and financial problem which lead to conduct cost benefit analysis. 3- the method used in the research for each objectives

- 24. C R O P S T O I N D U S T R Y

- 25. KENAF PRODUCTION IN MALAYSIA ECER(2010) States/year 2008 2009 2010 Tonne Rm Tonne Rm Tonne Rm Kelantan 58 114,000 1,970 985,000 5,000 2,500,000 Terengganu 30 9,000 941 470,500 5,100 2,550,000 Kedah 5 118,650 35 875 500 250,000 Perlis 1 2,500 19 475 500 250,000 Pahang - - - - 10,000 5,000,000 Total 94 244,150 1,456,850 1,456,850 21,150 10,555,00 0 2009a 2012 2015 Production target/Tonne 2,911 48,000 105,000 Productivity (per hectare/Tonne) 8,5 12 15 Planted area hectare 343 4,000 7,000

- 26. C R O P S T O I N D U S T R Y Technical, environmental and financial problems which lead to conduct cost benefit analysis. The production and usage of kenaf have more beneficial than harmful effects on the environment. Some of research results indicate that kenaf crop have benefit to environment over other annual energy crop systems, specifically, regarding pesticides and fertilizers inputs; Though, a negative impact of kenaf may rendered due to acidifying emission resulted from using of pesticides and fertilizers during kenaf cultivation (Fernando., etal2014). Kenaf has high potential manufactured products, but there is a paucity of studies evaluated both technical feasibility together with economic feasibility; Previous studies focused more on the problem with the production yields and the potential of Kenaf as a dry land crop, also there is lack of awareness and knowledge on the crop agronomy (Matata, Ajay, Oduol, & Agumya, 2010).

- 27. C R O P S T O I N D U S T R Y Cont. problem -Most of the research attentive on the characterizations of Kenaf accessions (Balogun, Raji, & Akande, 2008), the technical performance of the fibre (Muir, 2002), and the feasibility for pulp and paper manufacturing (Szabó, Soria, Forsström, Keränen, & Hytönen, 2009). (KPMG, 2013)”, stated many issues and problems from kenaf upstream, midstream and downstream faced kenaf industry in Malaysia, such as farmers knowledge with kenaf cultivation, the seed varieties of V36 which they cultivated has been weakened, slow developing of kenaf industry and other financial problems, these issues will consider to be one of the most motivated problems to study the cycle of kenaf industrialization in Malaysia.

- 28. C R O P S T O I N D U S T R Y Cont. kenaf is a quietly new crop in Malaysia, the local knowledge and experience is an inadequate and there is encouragement to create significant commercial processing and manufacturing capacities. There is a demand for non-wood renewable fibre for use in the industrial, construction, papers and automotive part industries as well as an increasing the demands of Malaysia kenaf stem locally and internationally from several companies such as Panasonic Electric work kenaf Malaysia SDN BHD and KEFI Italy (Junejo, Abdu, Hamid, Ahmed, & Akber, 2014).

- 29. C R O P S T O I N D U S T R Y Methodology Data collection Primary data Focus group discussion Interview Secondary data

- 30. C R O P S T O I N D U S T R Y

- 31. C R O P S T O I N D U S T R Y

- 32. C R O P S T O I N D U S T R Y Thank you very much Questions and Comments.